Slewing bearings play a vital role in various industries, providing rotational movement and stability to large-scale machinery and equipment. Understanding what slewing bearings are and their significance is essential for businesses looking to optimize their operations. In this comprehensive guide, we will delve into the world of slewing bearings, exploring their functionality, types, applications, and benefits. By the end of this article, you will have a solid understanding of slewing bearings and their importance in the industrial landscape.

Table of Contents

Definition of Slewing Bearing

Slewing bearings, also known as slewing rings or turntable bearings, are large-diameter bearings designed to handle axial, radial, and moment loads. They enable rotational movement between two components, such as a shaft and a fixed structure, while supporting heavy loads and providing stability. Slewing bearings are crucial for machines that require smooth and controlled rotation, allowing them to operate efficiently and safely.

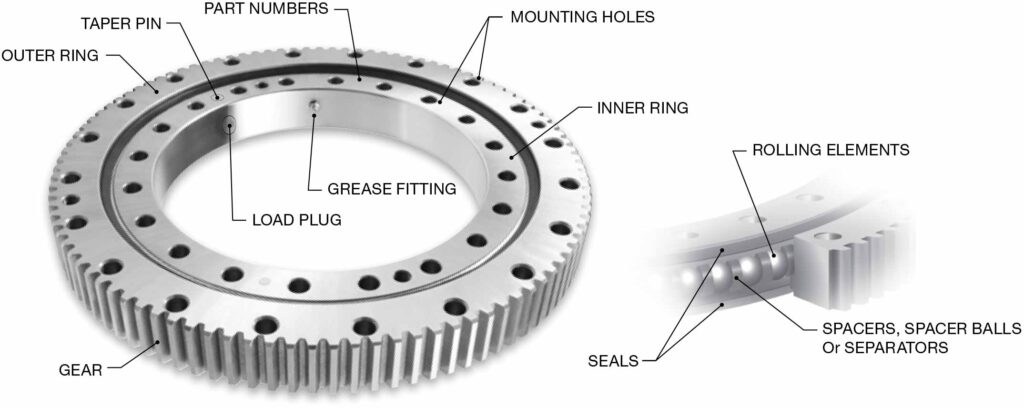

What Are the Parts of a Slewing Ring?

A slewing ring typically consists of several key parts that work together to facilitate controlled rotation and support various loads. The main parts include:

Outer Ring:

The outer ring is the stationary part of the slewing ring. It is usually attached to the stationary structure of the machinery or equipment.

Inner Ring:

The inner ring is the rotating part of the slewing ring. It is connected to the moving part of the machinery or equipment and rotates within the outer ring.

Rolling Elements:

Between the outer and inner rings, there are rolling elements, which can be either balls or cylindrical rollers. These elements facilitate smooth and controlled rotation by reducing friction between the two rings.

Raceways:

The raceways are the tracks or grooves along which the rolling elements move. There are typically two raceways on both the inner and outer rings, allowing for axial, radial, and moment load support.

Seals:

Seals are used to protect the internal components of the slewing ring from contaminants such as dust, dirt, and moisture. Effective sealing helps maintain the performance and longevity of the bearing.

How Do Slewing Bearings Work?

Two concentric rings make up the main structure of a slewing bearing. The outer ring usually lies flat against a motionless surface and is screwed into place via evenly spaced mounting holes.

The inner ring is usually affixed to a turning object via an adapter plate or bracket. It usually moves in a rotational manner while the outer ring stays affixed to the mounting surface.

Relative rotation between rings is facilitated either by rolling or sliding elements. For slewing rings that operate with ball bearings, parts that facilitate greasing of the system are included, such as seals, load plugs, grease fittings and taper pins.

For slewing rings that are based on sliding elements, replaceable plastic liners lie between the inner and outer rings.

Because slewing rings based on ball bearings have very small contact points (ball bearings touching the inner and outer ring surfaces), they are able to move with very low friction.

Slewing rings that are based on plastic liners to facilitate movement (with a larger inner ring surface to better handle heavier loads) work better for flat, horizontal applications . Vertical applications are better suited for ball bearing-based slewing rings.

Both slewing ring types can include gears on the outer ring OD or the inner ring ID to facilitate different application requirements.

Benefits of Slewing Bearings

excellent carrying capacity

These bearings can accommodate axial and radial loads, making them suitable for applications requiring heavy-duty performance. Additionally, slewing rings provide rotational precision, ensuring smooth and accurate movement even under heavy loads.

takes up minimal space

Its compact design allows efficient integration into machines and plants, optimizing space utilization. Additionally, slewing rings help reduce weight and increase energy efficiency by providing load carrying capacity in a relatively lightweight design.

can save costs

These bearings can withstand harsh operating conditions and require minimal maintenance. By minimizing downtime and reducing the need for frequent repairs, businesses can experience increased productivity, increased reliability and cost-effective operations.

What Are the Dimensions of Slewing Bearings?

The dimensions of slewing bearings can vary widely, but here’s an approximate numerical range for common specifications:

- Diameter: Common outer diameter range: 200 mm to 6,000 mm

- Inner Diameter: Common inner diameter range: 100 mm to 5,000 mm

- Height/Thickness: Common height/thickness range: 20 mm to 600 mm

What Are the Characteristics of Slewing Bearings?

Depending on their design, slewing bearings have the following features:

- High load carrying capacity

- High stiffness for rigid bearing application

- Low friction

- Long service life

- Surface protection and corrosion resistance

- Integration of additional features, including: Driving mechanism, Control devices, Lubrication systems, Monitoring systems, Sealing cassettes

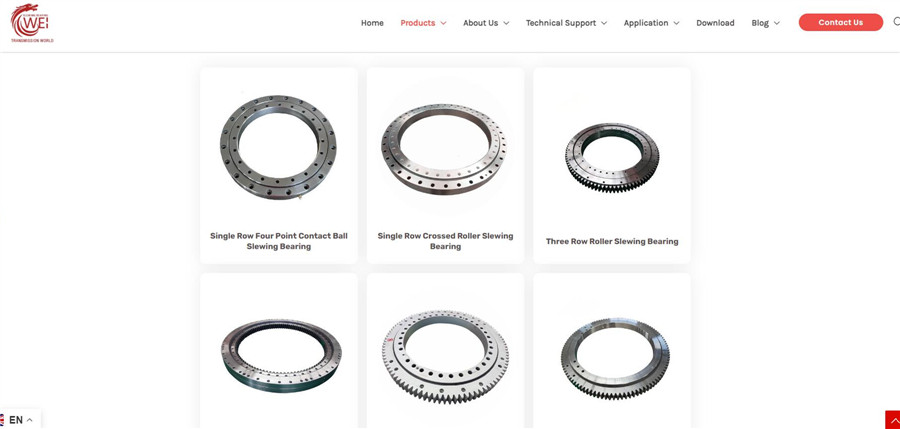

What Are the Types of Slewing Bearings?

The most common types include:

Single Row Ball Slewing Bearings: These bearings consist of a single row of balls mounted in a raceway, providing low friction rotation and excellent axial and radial load capacity.

Double Row Ball Slewing Bearings: These bearings have two rows of balls for higher load-carrying capacity and greater stability.

Crossed Roller Slewing Bearings: These bearings use cylindrical rollers arranged in a crossed configuration for high rigidity, precision, and shock resistance.

Three-Row Roller Slewing Bearings: These bearings have three rows of rollers and are ideal for handling heavy loads and moments.

Slewing Bearings in Industrial Applications

Construction and Heavy Machinery

In the construction and heavy machinery industries, slewing rings are widely used in excavators, cranes and concrete pumps.

wind power generation

The renewable energy sector relies heavily on slewing bearings for wind turbine applications. These bearings enable the rotation of the turbine blades, ensuring optimal wind capture and power generation.

Material Handling Equipment

Slewing bearings are widely used in material handling equipment, including conveyors, stackers and cranes.

Robotics and Automation Equipment

In robotics and automation, slewing bearings are used in robotic arms, turntables and other motion control systems.

How Much Does a Slewing Bearing Cost?

To get an accurate cost estimate, it’s advisable to contact slewing bearing manufacturers or suppliers directly. Provide them with detailed specifications, including size, load capacity, precision requirements, and any other specific features needed for your application.

Keep in mind that prices can vary between suppliers, so obtaining quotes from multiple sources is recommended for comparison.

Details: What is the price of the slewing bearing? How to estimate?

How Are Slewing Ring Bearings Made and Checked?

Like all bearings, slewing rings must be designed and built to stand up to repeated movement, consistent friction, and wear, high temperatures due to friction, and long-term, uninterrupted use.

In an excavator, even though the slewing ring might be very large, it must still be built to operate under precise and specific specifications. A poorly manufactured slewing ring bearing or heavily worn slewing ring will lead to inefficiencies in movement and even cascading adverse effects on a machine.

Since a slewing ring is mounted directly to upper and lower structures the mounting positions need to be flat and exact. Mechanics and operators consistently test the input needed to perform actions (as this indicates issues inside of the slewing ring) and measure the tolerance (play) of the slewing ring using a tool to check the distances of the parts as they rotate.

How to Choose High-Quality Slewing Bearings?

Choosing high-quality slewing bearings is crucial to ensuring the reliability and performance of machinery and equipment. Here are key considerations to help you select high-quality slewing bearings:

Load Capacity:

Determine the maximum axial, radial, and moment loads the slewing bearing will need to support. Choose a bearing with a load capacity that exceeds the requirements of your application to ensure longevity and safety.

Precision and Tolerance:

Consider the level of precision required for your application. High-quality slewing bearings are manufactured with tight tolerance levels, providing smooth and accurate rotation. Precision is particularly important in applications where positioning accuracy is critical.

Material Selection:

Choose a slewing bearing made from high-quality materials, typically alloyed steel or other specialized alloys. The right material selection ensures durability, resistance to wear, and the ability to withstand environmental conditions.

Sealing and Lubrication:

Check the sealing mechanisms and lubrication systems of the slewing bearing. Effective seals protect the bearing from contaminants, while proper lubrication ensures minimal friction and extends the bearing’s operational life.

FAQ

A1: A slewing bearing, also known as a turntable bearing, is a rotational component that supports axial, radial, and moment loads simultaneously. Its primary function is to enable smooth and controlled rotation between two connected structures, commonly used in heavy machinery and equipment.

A2: Slewing bearings find applications in various industries, including construction (cranes and excavators), renewable energy (wind turbines), mining, industrial machinery, robotics, and more. They are used wherever controlled rotation and load support are crucial.

A3: Consider factors such as the required load capacity, outer and inner diameter, height/thickness, and any specific dimensional requirements for your application. Consult with the manufacturer or use engineering calculations to ensure proper sizing.

A4: The cost is influenced by factors such as size, load capacity, material, precision, gearing (if applicable), customization, supplier reputation, and quantity. It’s important to balance cost with the specific requirements of your application.

A5: To ensure quality, consider factors such as load capacity, precision, material quality, sealing and lubrication, adherence to manufacturing standards, supplier reputation, customization options, and testing and inspection processes. Choose a reputable supplier with a history of delivering high-quality products.

A6: Yes, many manufacturers offer customization options for slewing bearings. This can include adjustments to dimensions, materials, sealing, gearing, and other features to meet the specific requirements of your application.

A7: Gearing in slewing bearings allows for controlled and synchronized rotation. It is necessary for applications where precise positioning or controlled movement is required, such as in cranes, robotics, and certain industrial machinery.

A8: Regular maintenance includes checking and replenishing lubrication, inspecting seals for damage, monitoring for unusual noise or vibration, and addressing any signs of wear. Follow the manufacturer’s guidelines for maintenance intervals and procedures.

A9: Look for certifications such as ISO 9001, which indicates that the manufacturer follows international quality management standards. Other industry-specific certifications may also be relevant, depending on your application.

A10: Yes, some slewing bearings are designed with corrosion-resistant materials or coatings to withstand harsh environments. It’s important to specify your environmental conditions when selecting slewing bearings for corrosive applications.

Conclusion

Choosing a suitable slewing bearing is not an easy task, especially when there are strict technical, reliability or economic requirements.

longwei is a professional slewing bearing manufacturer and exporter. We provide a wide range of slewing bearing value-added services around the world, including remanufacturing. We can provide the best solution for your project, if you need slewing bearings, then please contact us.

Recommended related content

How to Find Slewing Bearing Suppliers in China?

In today’s globalized world, finding a reliable slewing bearing supplier is crucial for companies. In particular, China, as an important base for global manufacturing, has abundant slewing bearing production resources and supply chains. However, due to the large number of suppliers on the market, how to select suppliers with good reputation, stable quality and high-quality

Slewing Bearing Manufacturer Purchasing Strategy

In the fields of heavy machinery, wind power generation, engineering equipment, etc., slewing bearings are one of the core components, and their quality and stability are directly related to the safe operation of the equipment. Therefore, it is crucial to choose a reliable slewing bearing manufacturer. Procurement personnel are not only concerned about the quality

Slewing Bearing Complete Analysis and Purchase Guide

Slewing bearings play a vital role in modern industrial equipment and mechanical systems. Whether it is construction machinery, wind power generation, or robotics, slewing bearings can provide smooth rotational motion and high load capacity to ensure efficient operation of equipment. However, faced with a wide range of bearing types on the market, how to

Top 10 Slewing Bearing Manufacturers in China 2025

Are you looking for China High Quality Slewing Bearing Company? Look no further! In this article, we’re going to discuss 10 of the best suppliers in the country. Each of these companies offers quality slewing bearing products and services, so you’re sure to find one that fits your needs. Read on to learn more about

Top 10 Slewing Bearing Manufacturers & Supplier 2025

Are you looking for a reliable slewing bearing manufacturer or supplier to customize slewing bearings for your project? Then you’ve come to the right place! No matter what you need is in industrial slewing bearings, agricultural slewing bearings, you can find suitable manufacturing here. Next, we mainly recommend the top 10 slewing bearing manufacturers in

8 Key Tips for Understanding Slewing Bearing Inspection Standards

How can you assess the quality of a slewing bearing after purchasing it? What are the inspection standards for slewing bearings? Today, the slewing bearing manufacturer, Longwei Slewing Bearings, will guide you through our slewing bearing inspection standards. Generally, the inspection of slewing bearings requires adherence to the following 17 slewing bearing inspection standards: