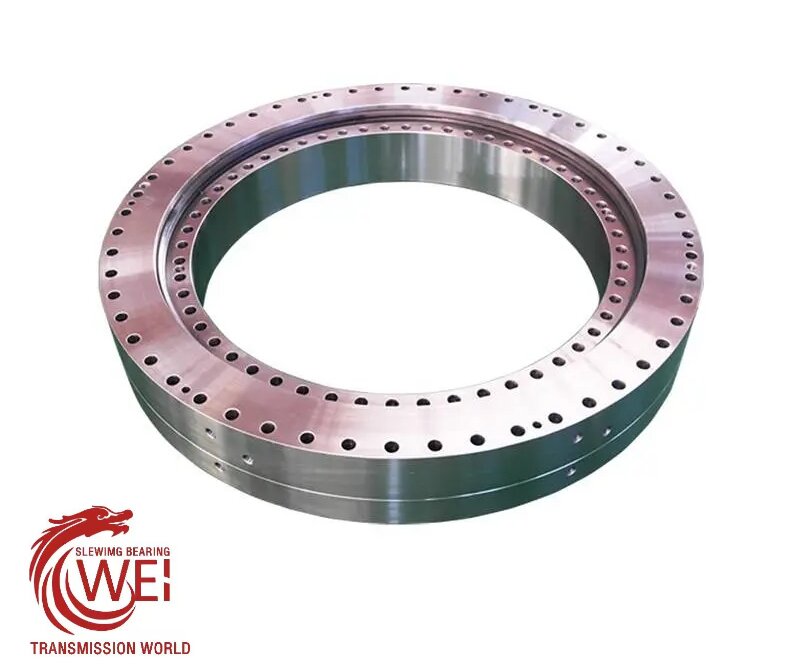

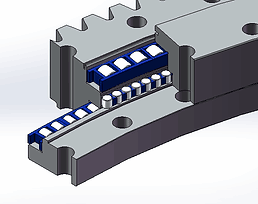

The slewing bearing has no tooth type, internal tooth type and external tooth type , four-point contact ball bearing, double row Angle contact ball, cross assistance roller support, cross cylindrical roller support and three rows of cylindrical roller combination support and other structural forms. The four-point contact ball bearing has higher static load capacity. The cross cylindrical roller bearing has higher dynamic load capacity. Cross tapered roller bearings have larger supporting rigidity and higher rotary accuracy through pre-interference, so with the development of industrial modernization, the application range of slewing bearings is gradually expanding.

Slewing bearing is also called slewing ring bearing 、 turntable bearing、slewing ring, rotation.

The three-row roller slewing ring has three races, and the upper, lower and radial raceways are separated, so that the load of each row of rollers can be accurately determined.

It can bear various loads at the same time. It is the largest of the four products. The shaft and radial dimensions are relatively large.

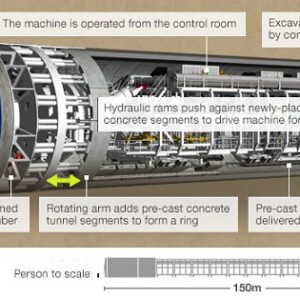

Three row roller slewing bearing is an important transmission component. In order to achieve relative rotation, it needs to bear a lot of force during the operation. With the wide use of various mechanical equipment, three row roller slewing bearing is the most important part of the equipment. Essential accessories are widely used in various construction machinery, medical machinery and industrial equipment, and have been highly recognized. The external gear of light series slewing bearing is an essential product in three row roller slewing bearing. If the equipment is worn during operation, it can be lubricated between multiple parts to reduce friction and tear. It is better to stop the equipment and conduct detailed inspection to enhance the operation of the whole mechanical equipment. Meanwhile.

In order to prolong the service life of the three row roller slewing bearing in the machine, it is usually best to pay attention to the corrosion of the product to the corrosive product and take anti rust measures. Usually, clean the surface regularly and use the cleaning effect. It is better to keep the product surface dry at the same time, pay attention to the application of anti rust oil, if you encounter special circumstances, you can choose to use antirust oil. In fact, three row roller slewing bearing is a very good product. It is better not to touch it with hands when not in use, so as not to corrode the bracket.

As an important part of industrial parts, three row roller slewing bearing is the biggest problem faced by industry. There was no improvement. Only by continuous research and development, improving product design and structure, can the industry have better development and momentum. For example, in the production process of parts, the accuracy problem is still very worthy of our attention. At present, the accuracy of the parts is about minus 0.5mm, but we should also pursue more accurate and more accurate precision, such as 0.2mm, only enough target. This product can get new development.

Another example is the material built on a three row roller slewing ring, which is also a big problem. The alloy used more than ten years ago has not been improved, so attention must also be paid to it. It should be more appropriately designed and new materials that are easy to use should be used. Finally, parts are used in the structure. Now, this support usually consists of four parts. We don’t seem to care that support can be divided into three parts or even parts. In this respect, we need to invest enough manpower and resources.

FAQ

1: How to order?

Please refer to the help under the single payment.

2.What are the shipping methods?

Ocean shipment to the port close to your city; Air shipment to the airport close to your company; Door to door service by international express.

3.When can I get the price?

We usually quote within 12 hours after we get your inquiry. If urgent to get the price, please call us or tell us by email , we will regard your inquiry priority.

4.You are a trader or a manufacturer?

We are an industry and trade integration business, our factory located on Xuzhou City.

5.How about the payment terms?

We usually accept T/T or L/Cat sight . other terms also could be negotiated.

6.What is your minimum order?

It depends on what you are buying. Normally, our minimum order is 1pcs.

7.What is your delivery time?

If there are any parts in stock , our delivery time is only 3-7 days. If our standard model,the delivery time is around 25 days,if non-standard model,the delivery time is 38~45 days.

Reviews

There are no reviews yet.