Four-point Contact Ball Swing Bearing with Deformable Rings.In general, the slewing bearing rolling elements are integrally hardened carbon-chromium bearing steel. The grade is made of GCr15 or GCr15SiMn steel; the slewing bearing ring is made of surface hardened steel. When the user has no special requirements, it is generally made of 50Mn steel, but sometimes it can be provided according to the needs of some special applications. For the specific conditions of use, other grades of surface hardened steel, such as 42CrMo, 5CrMnMo, etc., are selected.

How to do the initial selection

Four-point Contact Ball Swing Bearing with Deformable RingsHow to Purchase Slewing Support, many new contacts do not know how to choose, want to buy or customize the slewing bearing but do not know which model to use, do not know how to do the initial selection.

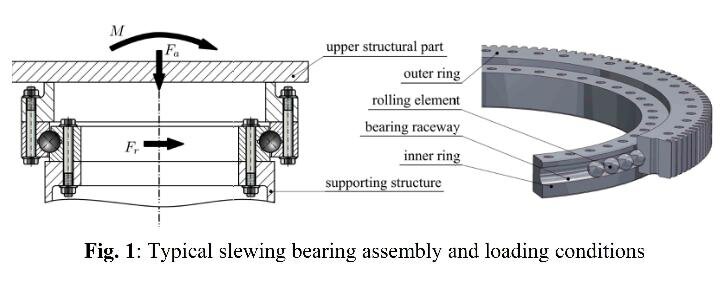

- Determine the large load (axial load, radial load, overturning moment) that the slewing bearing is subjected to when it is in a static state according to the use environment. Use this large load as a static rating.

- Determine the static safety factor based on the type of machine installed.

- Refer to the slewing bearing catalogue of the extension slewing bearing to initially select the slewing bearing model and determine which formula is used to calculate the static reference loads Fa’ and M’.

- Calculate the static reference loads Fa’ and M’.

- Find the static load-bearing curve corresponding to the slewing bearing of the selected model in the Slewing Bearing Product Catalogue, marked in the graph (Fa’, M’)

- Check if the coordinate point is within the static bearer authority.

- Check the bolt bearing capacity.

- Complete preliminary selection.

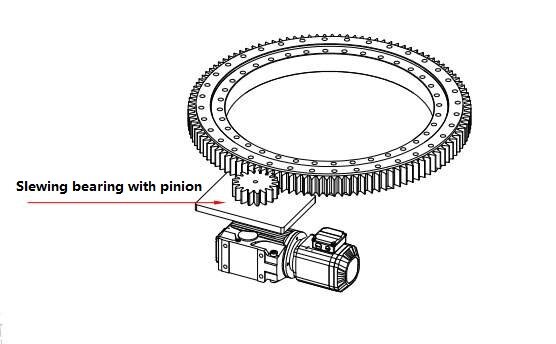

The motor or reducer drives the pinion to rotate, and the pinion drives the slewing bearing to rotate, thereby achieving the effect of driving the rotating platform to rotate.

The slewing bearing used in the carousel is required to carry a large axial force, a certain overturning moment, and has a high stability. Selecting the slewing bearing of appropriate size can effectively achieve the effect of smooth and safe operation.

Longwe Transmission slewing bearing team is committed to keep the spirit of continuous improvement and focus our strategy of strict quality control standards, quick response, prompt delivery and low price.We look forward to working on all of our customers’ growing demands. Our ability to optimize the bearing design for your specific needs is unparalleled and we will assist you throughout the design, manufacturing and implementation process.

We supplied high quality product & good service to every end user and valued distributors all over the world. We’ve enjoyed a very good reputation up to now.

Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements and has acquired certificate of China Classification Society .

If you have any questions, pls do not hesitate to contact us.

Reviews

There are no reviews yet.