Application of slewing bearing

The main structural form of the slewing bearing used by the wood grabber is a single-row ball slewing bearing or a slewing drive. The use position

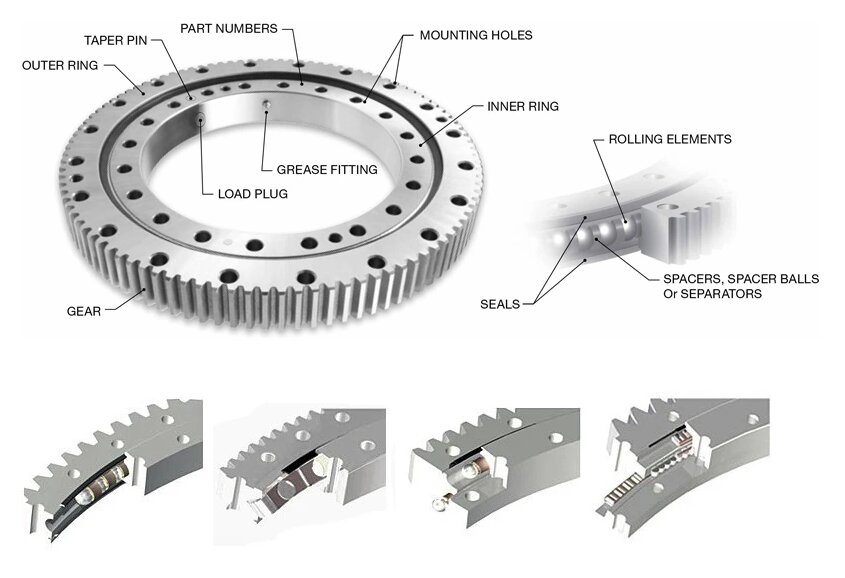

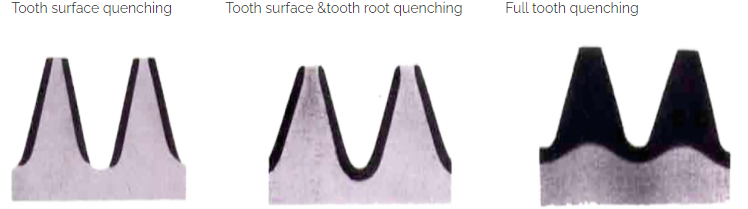

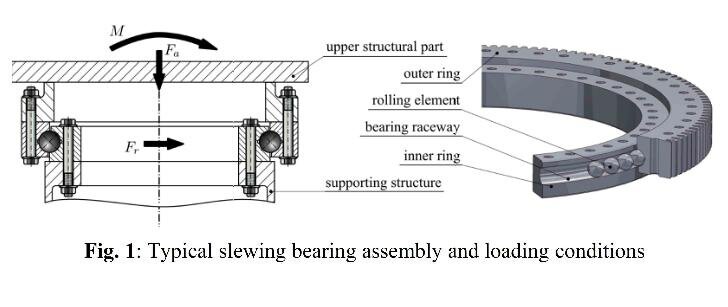

① is the connection part between the base and the upper mechanism, and② is the connection part between the gripper and the mechanical arm. ①The slewing bearing is an internal gear slewing bearing, which requires tooth quenching treatment to carry a certain axial force and overturning moment; ②The slewing bearing is an external gear slewing bearing or slewing drive, which bears a certain axial force and impact force.

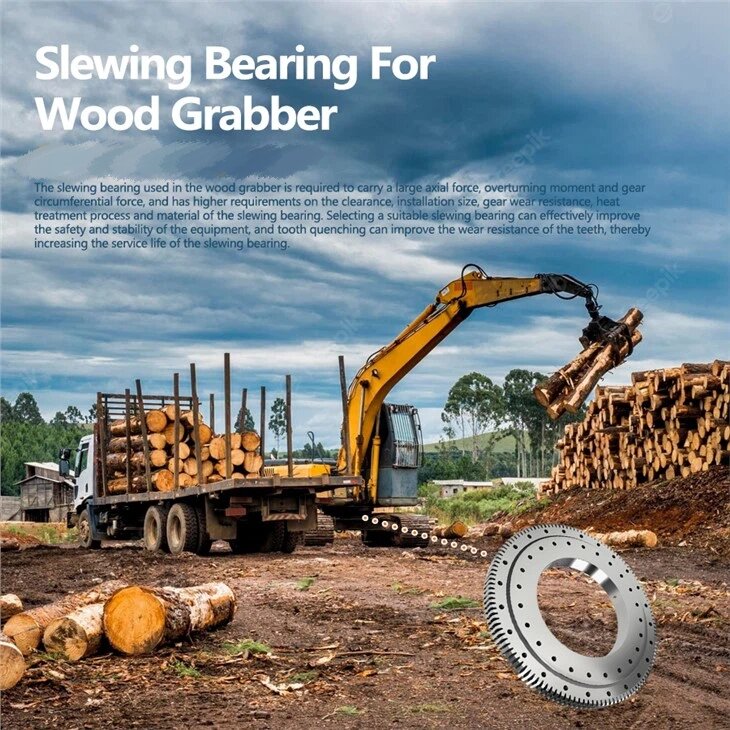

Why use a slewing bearing?

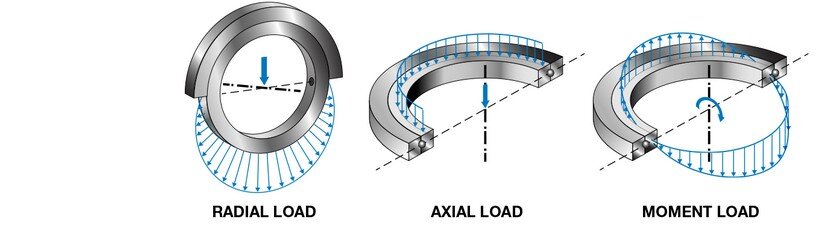

The slewing bearing used in the wood grabber is required to carry a large axial force, overturning moment and gear circumferential force, and has higher requirements on the clearance, installation size, gear wear resistance, heat treatment process and material of the slewing bearing. Selecting a suitable slewing bearing can effectively improve the safety and stability of the equipment, and tooth quenching can improve the wear resistance of the teeth, thereby increasing the service life of the slewing bearing.

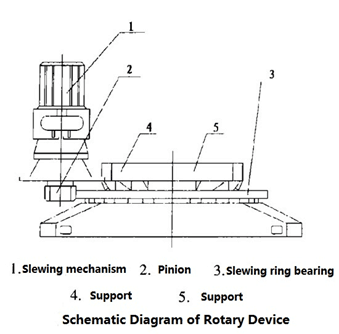

Application principle of slewing bearing

The motor or reducer drives the pinion or worm to rotate, and the pinion or worm drives the slewing bearing to rotate, so that the mechanism connected to it rotates, so as to control the steering of the cab, the mechanical arm and the gripper.

Longwe Transmission slewing bearing team is committed to keep the spirit of continuous improvement and focus our strategy of strict quality control standards, quick response, prompt delivery and low price.We look forward to working on all of our customers’ growing demands. Our ability to optimize the bearing design for your specific needs is unparalleled and we will assist you throughout the design, manufacturing and implementation process.

Products type | 1.single – row four – point contact ball |

Special services | 1.slewing bearing design |

Business type | manufacturer,trading company |

Advantages | 1.ISO 9001:2008 certificate,12 years experience2.High qualified material,low MOQ,excellent quality,competitive prices, |

Material | 50Mn/42CrMo or as your requirements |

Package | 1.First lubricated, Second circled with plastic film,kraft paper,blue belt,then packaged inwooden case,last gathered in Wooden pallet.2 According to your requirements

|

Delivery time | 1.For general product , our delivery time need only 5 days is enough (goods in stock).2.If you have special technical requirements or need additional processing,we first rder need only 45 ys, if that is roller continuous order, our delivery time only need 35 ys.

|

Application ields | Mine machine, port hoisting machine, port oil transfer equipment onshore and offshorecrane,excavator,concrete machine,paper machine, plastic and rubber machine, weavemachine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipment.

|

We supplied high quality product & good service to every end user and valued distributors all over the world. We’ve enjoyed a very good reputation up to now.

Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements and has acquired certificate of China Classification Society .

If you have any questions, pls do not hesitate to contact us.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.