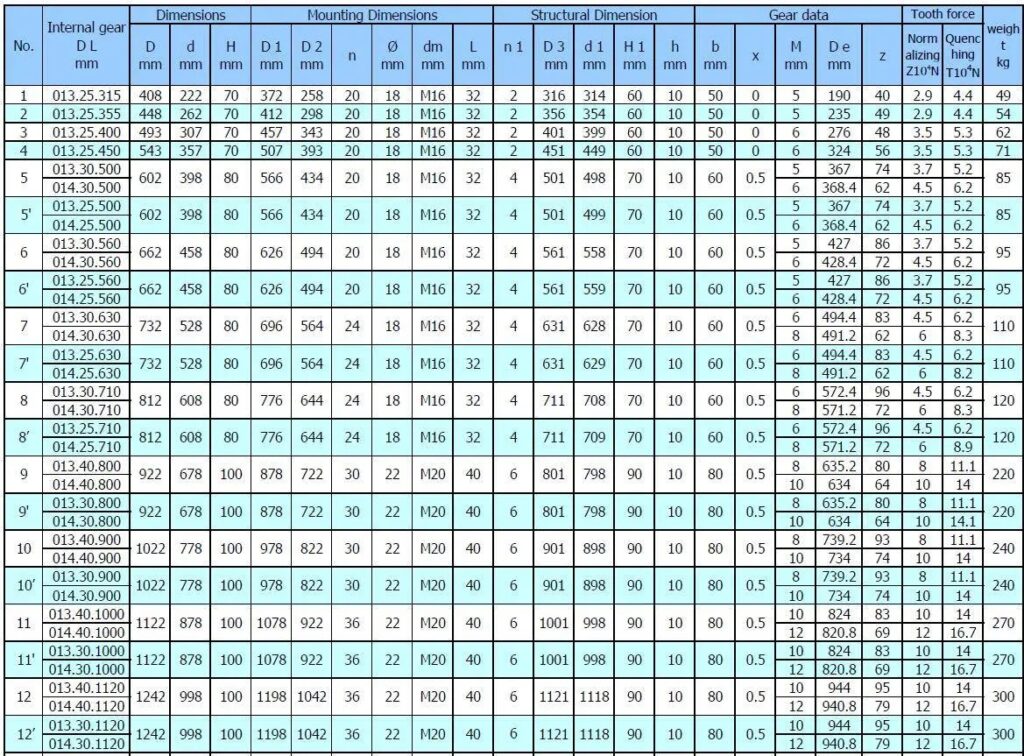

Internal tooth slewing bearing single row ball 4-point contact 013 series

The inner and outer gears of the slewing ring are directly toothed on the inner or outer ring, and are processed by a gear hobbing machine or a gear shaper. If the working environment is loaded, it needs to be quenched. The internal gear slewing ring: the overall appearance is relatively neat, There is no need to install a safety cover at the meshing part of the gear and the slewing ring. The gear has better dust resistance, longer retention time by adding lubricant, and lower transmission contact stress of internal gear meshing, less wear and longer service life.

Note:

- n1 is No. of lube holes, the user can specify the lube hole position.

- n-φ can be changed to threading holes, hole diameter M, thread depth 2M.

- There are standard products in the catalog, and the inner and outer diameters are random tolerances. If there is a locating requirement for slewing bearing, please indicate the site and tolerance.

- It is standard type of our products, if you need more please contact with engineer.

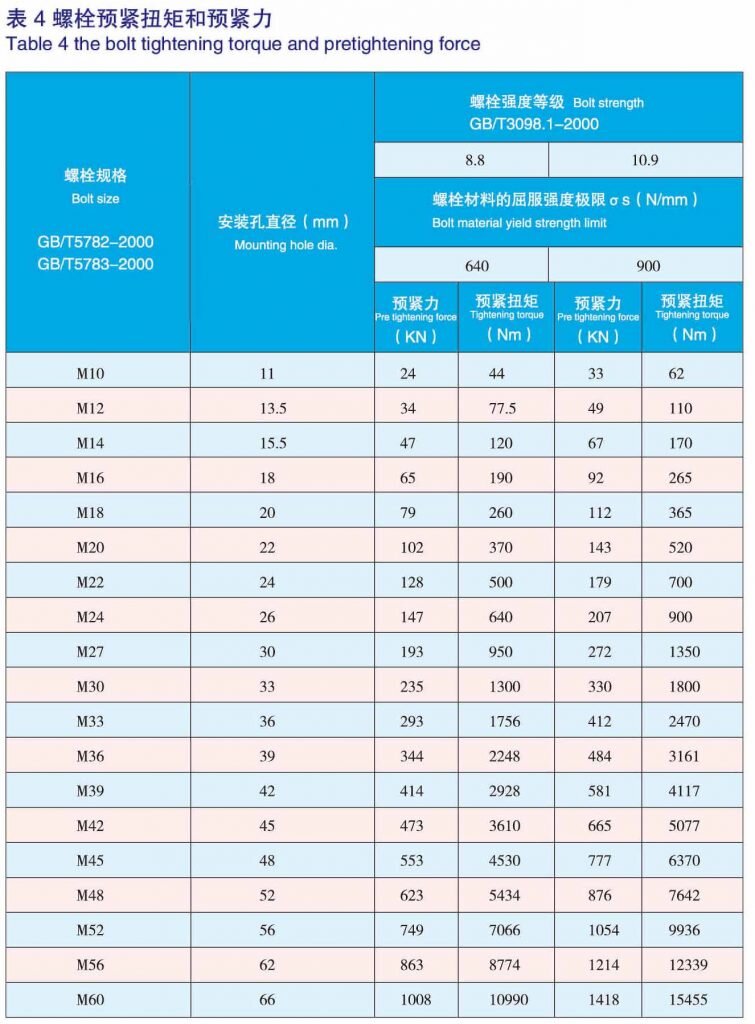

If it is an internal gear type, the outer gear ring should be fixed with bolts of appropriate strength grade. The bolts and nuts should meet the standards of GB3098.1 and GB3098.2. Then the pinion gears mesh with the inner teeth to drive the inner ring to rotate to achieve the purpose of transmission.

One of the most common applications is excavators. Generally, excavators need to use internal tooth slewing bearings, and the internal teeth need to be quenched to increase the hardness of the teeth.

SLEWING BEARING SELECTION

How to Purchase Slewing Support, many new contacts do not know how to choose, want to buy or customize the slewing bearing but do not know which model to use, do not know how to do the initial selection.

Method 1 BY slewing ring bearing selector

slewing ring bearing selector allows engineers and designers to easily search ‘s slewing bearings catalog by bearing type, gear type, external and internal dimensions, static loads, and other parameters. Results include the option to download PDF drawings.

SEARCH BY REQUIREMENTS

Longwei transmission Slewing Bearing Co.,Ltd

Choose inch or metric, select an application from the drop-down menu, and specify one or all of the factors below. Required fields are indicated.

If needed ,you can also download our slewing ring design guide downlaod Slewing bearing selection PDF

LONGWEI TRANSMISION SLEWING BEARING CO., LTD Slewing Bearing Selection

| |||||||||||

Company: Add.: | |||||||||||

Contact Person: Dept.: | |||||||||||

Tel: Fax: | |||||||||||

Application: | Shaft Position | Slewing Bearing Mounting Method | |||||||||

| Horizontal □ Vertical □ | Seat type □ Suspended □ | |||||||||

Tooth type: | Movement: | Speed (RPM): | |||||||||

External Tooth □ | Positioning only□ | Normal working speed: | |||||||||

Internal Tooth □ | Intermittent rotation □ | Max speed: | |||||||||

Without Tooth □ | Continuous rotation □ |

| |||||||||

Load data | |||||||||||

Bearing load

Loading type | A | B | C |

| |||||||

max. working load | max. test load e.g. 25% overload condition | Extreme load e.g. shocks or out of operation |

| ||||||||

Axial loads parallel to axis of rotation |

|

|

| KN | |||||||

Radial loads at right angle to axis of rotation (without gear loads) |

|

|

| KN | |||||||

Tilting moment generated by axial load |

|

|

| KN·m | |||||||

Tilting moment generated by radial load |

|

|

| KN·m | |||||||

Final tilting moment |

|

|

| KN·m | |||||||

Driving Torque on Slewing Bearing [KN] Normal: Max: | No. of Driving Pinions: Position: ° (distribution) | ||||||||||

Slewing bearing type and dimension | |||||||||||

Type: light type□ single row ball □ double row ball□ single row cross roller□ triple row cross roller□ | |||||||||||

| |||||||||||

Dimension: OD: mm □ ID: mm □ Height: mm □ | |||||||||||

For continuous rotation, variable and life requirements, please complete annex A. | |||||||||||

Annex A is enclosed: | |||||||||||

Remarks: (e.g. special working conditions / temperatures, required accuracies, bearing dimensions, inspection- or certification requirements, material tests etc.) | |||||||||||

Please fully complete this form. Incomplete information will delay our proposal.

| |||||||||||

Tel: 86-516- 85588998 Fax: 86-516- 85819994 Email: yang788888@gmail.com | |||||||||||

Signature: date: | |||||||||||

| |||||||||||

Appendix A The percentage of working time and rotation speed under different load cases. | |||||||||||

Slewing Ring Load Data

| |||||||||||

Load cases | axial (KN) | radial (KN) | Moment (KN·m) | rotation speed (rpm) | time (%) | ||||||

1 |

|

|

|

|

| ||||||

2 |

|

|

|

|

| ||||||

3 |

|

|

|

|

| ||||||

4 |

|

|

|

|

| ||||||

5 |

|

|

|

|

| ||||||

6 |

|

|

|

|

| ||||||

7 |

|

|

|

|

| ||||||

8 |

|

|

|

|

| ||||||

9 |

|

|

|

|

| ||||||

10 |

|

|

|

|

| ||||||

|

|

|

|

| 100% | ||||||

Continuous operation: | |||||||||||

The service life(L10) : at average speed: rpm, service life is at least: /hour | |||||||||||

Intermittent operation: | |||||||||||

Working life needed: at angle+/- °, the least recycle number: | |||||||||||

Signature: date: | |||||||||||

Appendix B | |||||||||||

Gear data | |||||||||||

External tooth □ Internal tooth □ Involute tooth □ | |||||||||||

Tooth Data | |||||||||||

Definition | Slewing ring tooth | Pinion tooth | |||||||||

Module (m)

|

|

| |||||||||

Number of teeth (z)

|

|

| |||||||||

Pressure angle (α)

|

|

| |||||||||

Helix angle (β)

|

|

| |||||||||

Modification coefficient (x)

|

|

| |||||||||

Coefficient of top clearance ©

|

|

| |||||||||

Teeth width (b)

|

|

| |||||||||

Precision grade (l)

|

|

| |||||||||

Gear center distance is adjustable | yes □ no □ | ||||||||||

Please attach the drawing of pinion.

|

| ||||||||||

Other requirements

|

| ||||||||||

Signature date: | |||||||||||

| |||||||||||

Method 2 : According to the catalog of slewing bearing products provided by our company and relevant calculation formulas, calculate on your own,Then discuss and confirm with our engineers。

- Determine the large load (axial load, radial load, overturning moment) that the slewing bearing is subjected to when it is in a static state according to the use environment. Use this large load as a static rating. . 2. Determine the static safety factor based on the type of machine installed

- Refer to the slewing bearing catalogue of the extension slewing bearing to initially select the slewing bearing model and determine which formula is used to calculate the static reference loads Fa’ and M’.

- Calculate the static reference loads Fa’ and M’.。

- Find the static load-bearing curve corresponding to the slewing bearing of the selected model in the Slewing Bearing Product Catalogue, marked in the graph (Fa’, M’)

- Check if the coordinate point is within the static bearer authority.

- Check the bolt bearing capacity.

- Complete preliminary selection

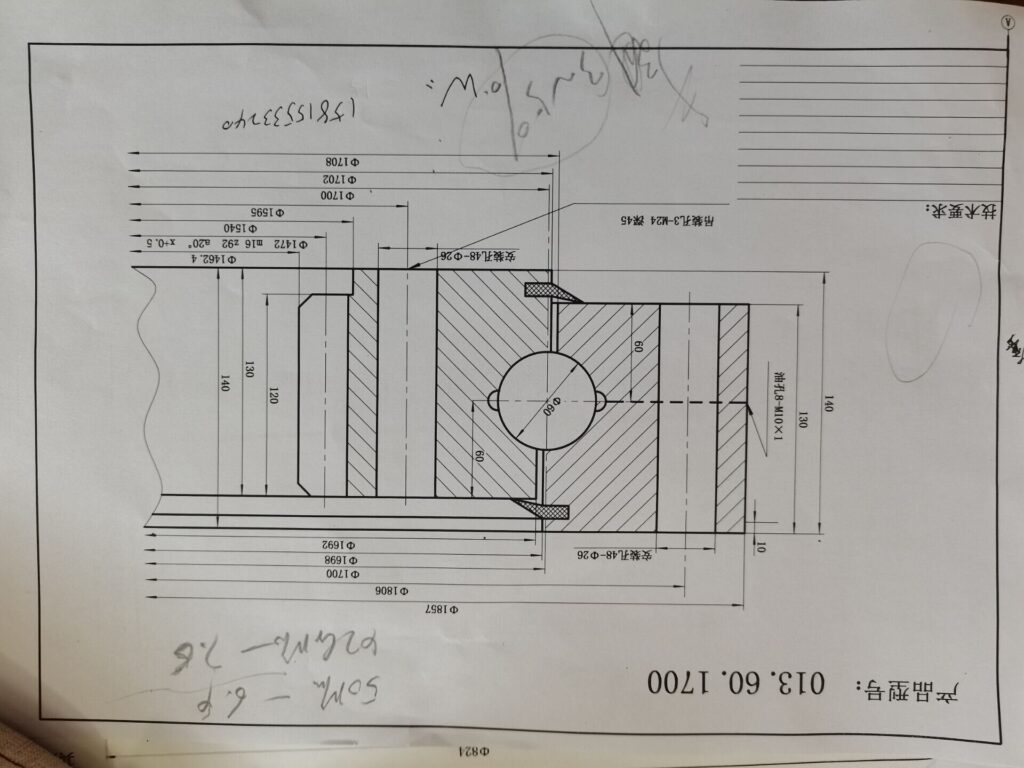

Method 3 : By the buyer‘s drawing :

For example :

Longwe Transmission slewing bearing team is committed to keep the spirit of continuous improvement and focus our strategy of strict quality control standards, quick response, prompt delivery and low price.We look forward to working on all of our customers’ growing demands. Our ability to optimize the bearing design for your specific needs is unparalleled and we will assist you throughout the design, manufacturing and implementation process.

Products type | 1.single – row four – point contact ball |

Special services | 1.slewing bearing design |

Business type | manufacturer,trading company |

Advantages | 1.ISO 9001:2008 certificate,12 years experience2.High qualified material,low MOQ,excellent quality,competitive prices, |

Material | 50Mn/42CrMo or as your requirements |

Package | 1.First lubricated, Second circled with plastic film,kraft paper,blue belt,then packaged inwooden case,last gathered in Wooden pallet.2 According to your requirements

|

Delivery time | 1.For general product , our delivery time need only 5 days is enough (goods in stock).2.If you have special technical requirements or need additional processing,we first rder need only 45 ys, if that is roller continuous order, our delivery time only need 35 ys.

|

Application fields | Mine machine, port hoisting machine, port oil transfer equipment onshore and offshorecrane,excavator,concrete machine,paper machine, plastic and rubber machine, weavemachine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipment. |

We supplied high quality product & good service to every end user and valued distributors all over the world. We’ve enjoyed a very good reputation up to now.

Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements and has acquired certificate of China Classification Society .

If you have any questions, pls do not hesitate to contact us.

FAQ :

1 LW Slewing Bearing Heat Treatment

Heat Gear Slewing Bearings are in the majority of cases supplied with spur tooth. Stub teeth also is ok.There are two kinds of tooth hardening. They are normalizing and tempering, According to the different applications, there are two ways of quenching. They’re whole tooth quenching and single-tooth quenching. Single-tooth quenching can be divided into tooth surface & root quenching and tooth surface quenching.

2 . The Calculation of Slewing Bearing.

Static load capacity

The determined loads must be multiplied with a factor fstat allocated to the application. The product Fa’ or Mk’ must be below the static critical load curve of the selected bearing.

With regard to radial loads in load combinations

Fa = axial load

Fr = radial load

Mr = tilting moment

3 Protection Against Corrosion

We make Protection Against Corrosion on surface of bearing,and make couple of packing paper.

4.Customize.

Yes,we have professional technical terms.

5.Warranty:

General 1 year.

- Reliable reputation.

Reviews

There are no reviews yet.