Slewing ring bearings, or turntable bearings, are ball or roller style bearings composed of two concentric rings either of which may include a gear. This type of bearing enhances load support and power transmission in all directions, and is typically employed to support heavy loads for slow applications and large equipment such as earth excavators and construction cranes. The unique power and versatility of slewing ring bearings has made them increasingly valuable in a wide array of industries, including construction, industrial, robotics, machine tooling, and medical applications.

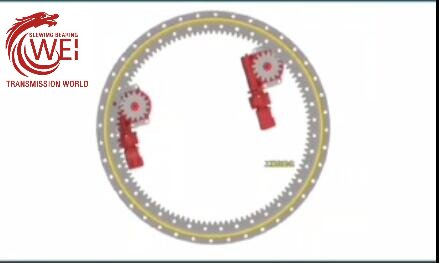

Application principle of slewing bearing

The motor or reducer drives the pinion to rotate, and the pinion drives the slewing bearing to rotate, so that the upper mechanism connected to it rotates accordingly.

Slewing ring bearings, or turntable bearings, are ball or roller style bearings composed of two concentric rings either of which may include a gear. This type of bearing enhances load support and power transmission in all directions, and is typically employed to support heavy loads for slow applications and large equipment such as earth excavators and construction cranes. The unique power and versatility of slewing ring bearings has made them increasingly valuable in a wide array of industries, including construction, industrial, robotics, machine tooling, and medical applications.

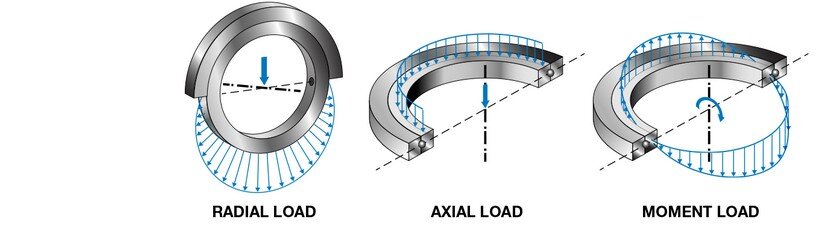

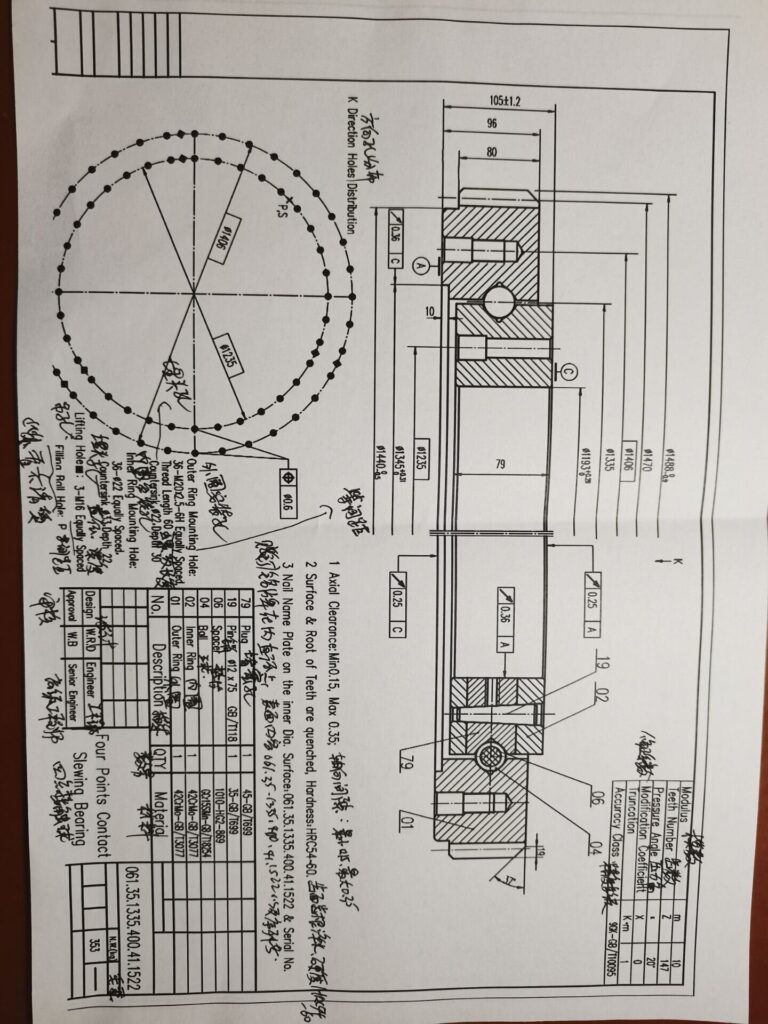

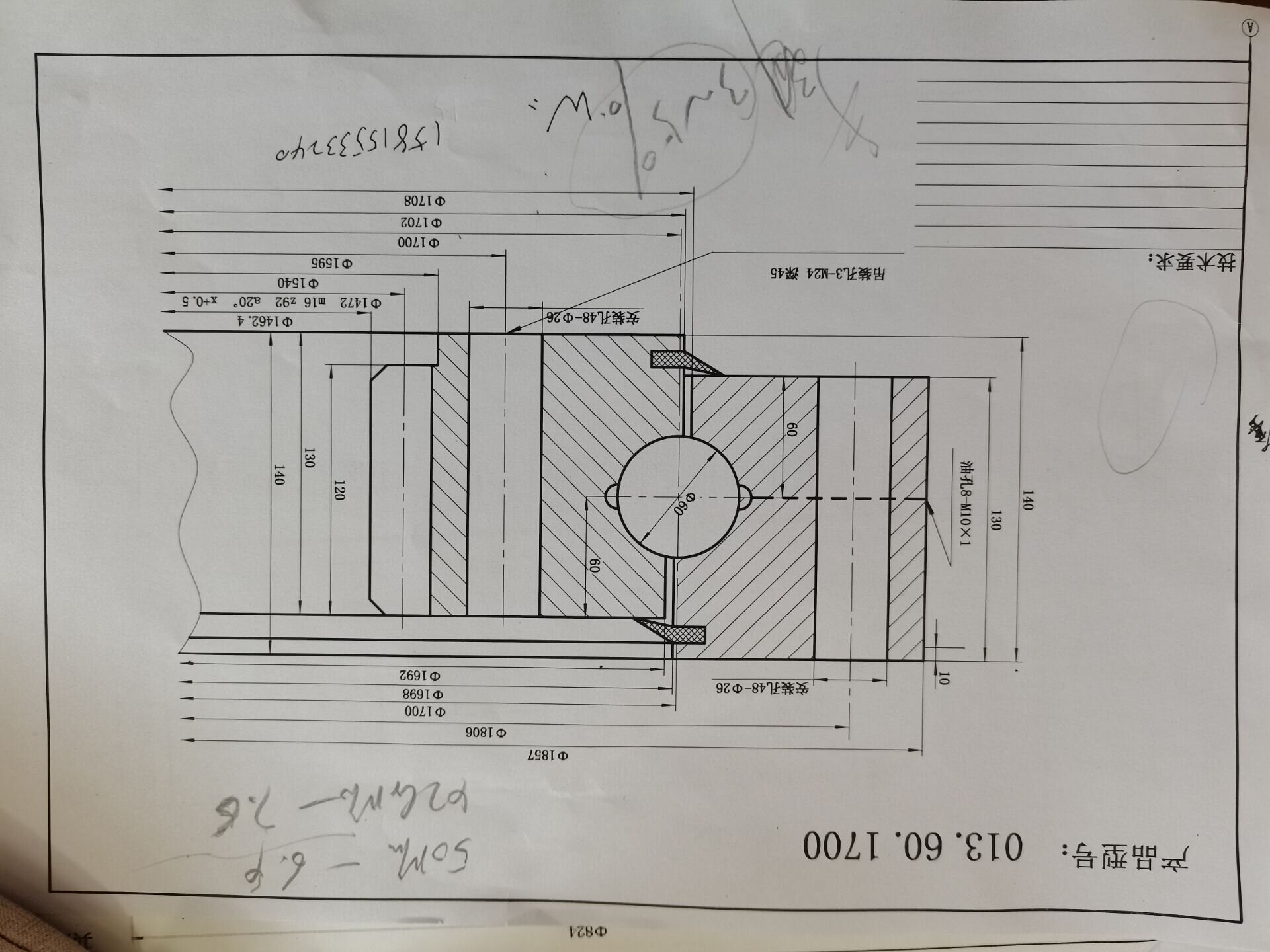

The single row four point contact ball slewing bearing is composed of two seat rings, which design in compact structure and light weight, steel ball contact with the circular raceway at four point, it can bear the axial force, radial force and the tilting moment at the same time.

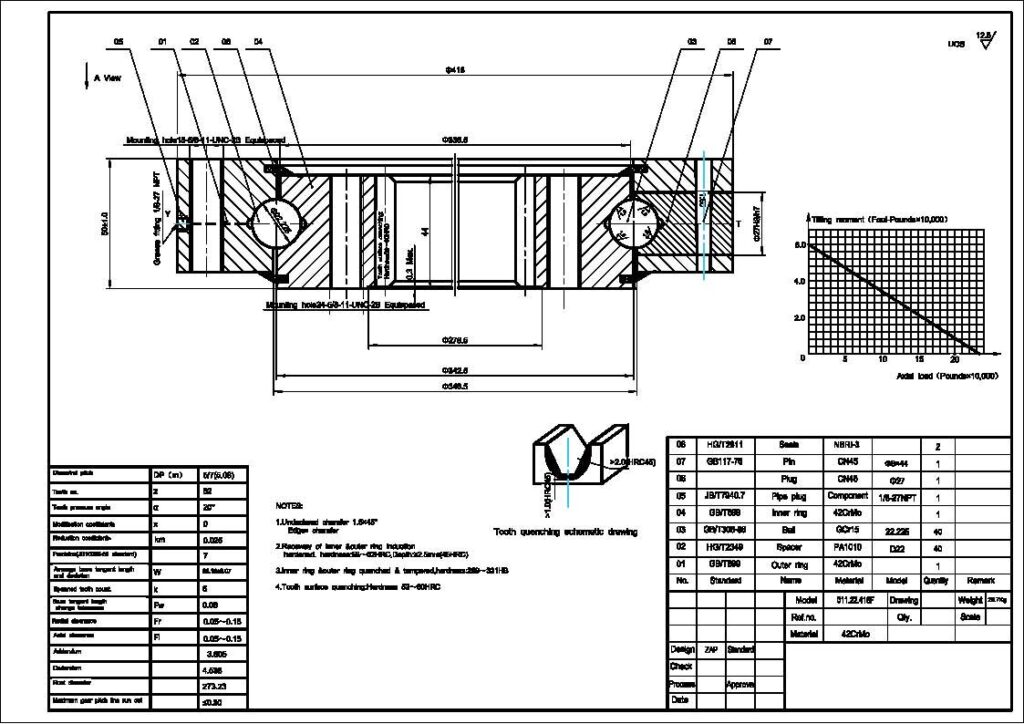

Slewing ring bearings are comprised of two rings, each of which contains a precision raceway that is induction hardened on the surface to a specified depth. Each ring is made from a medium carbon steel forging.

Series bearings have raceways constructed in a four-point contact configuration, with 45° contact angles as standard. Other raceway configurations are available, such as crossed roller and eight-point contact. These other options are often considered in cases where very high loads or special stiffness requirements are needed.

Mounting holes are generally spaced around the faces of the inner and outer ring along a uniform bolt circle and equal spacing. These holes can be thru holes, tapped holes, blind tapped holes, counter-bored holes, etc. Sometimes bolt circle or spacing requirements need to be customized to meet the demands of a specific application, in which case custom options are available. In the case of either the standard part numbers listed in this catalog, or other custom versions provided the equipment designer, manufacturer, or user is responsible to determine that the mounting design is adequate.

Slewing ring bearings can be supplied as ungeared, or with gears on either the ID of the inner ring or the OD of the outer ring. Gears are typically a standard stub involute spur gear with backlash provisions and AGMA Q8 quality minimum.

Details for each bearing can be found in the enclosed dimensional tables, and drawings are available. Custom gear configurations are also available.

At least one grease fitting is included in one of the rings. The quantity may increase with the diameter of the bearing. For bearings with gears, the grease fitting(s) are located on either the ID or OD of the ungeared ring. For ungeared bearings,come equipped to accommodate grease fittings on either the inner or outer ring. Custom quantities, locations and configurations for grease fittings are available.

FAQ :

1 LW Slewing Bearing Heat Treatment

Heat Gear Slewing Bearings are in the majority of cases supplied with spur tooth. Stub teeth also is ok.There are two kinds of tooth hardening. They are normalizing and tempering, According to the different applications, there are two ways of quenching. They’re whole tooth quenching and single-tooth quenching. Single-tooth quenching can be divided into tooth surface & root quenching and tooth surface quenching.

2 . The Calculation of Slewing Bearing.

Static load capacity

The determined loads must be multiplied with a factor fstat allocated to the application. The product Fa’ or Mk’ must be below the static critical load curve of the selected bearing.

With regard to radial loads in load combinations

Fa = axial load

Fr = radial load

Mr = tilting moment

3 Protection Against Corrosion

We make Protection A

gainst Corrosion on surface of bearing,and make couple of packing paper.

4.Customize.

Yes,we have professional technical terms.

5.Warranty:

General 1 year.

- Reliable reputation.

Reviews

There are no reviews yet.