Note

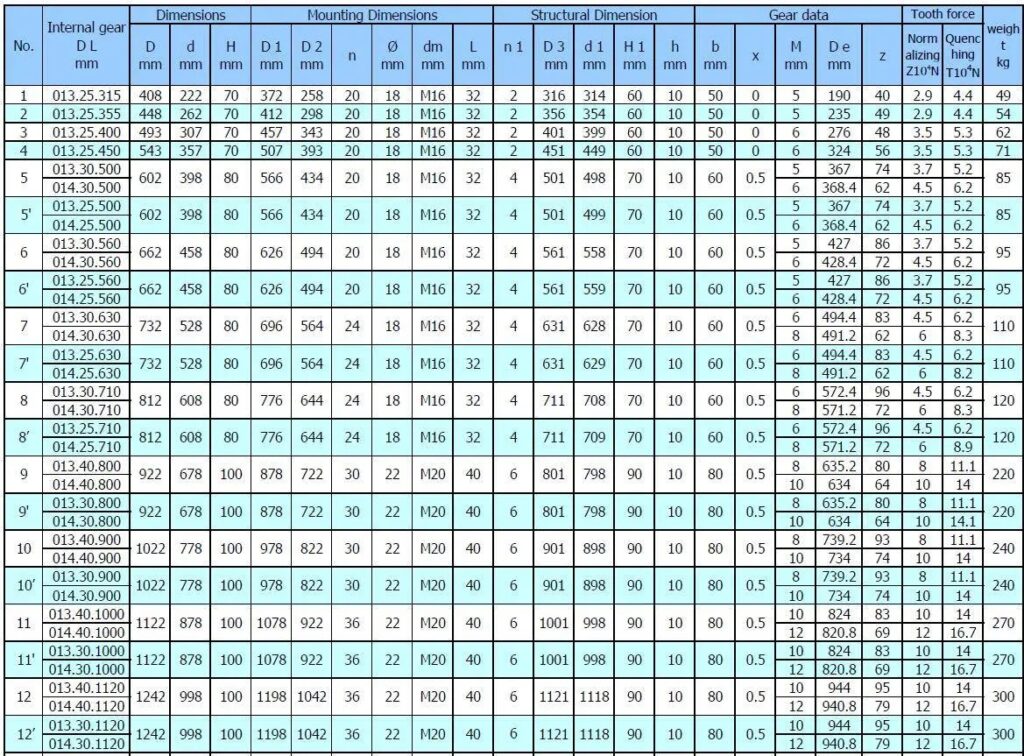

1. n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2.The Oil nipple’s location can be change according to the user’s application.

2. n-φcan change to tapped hole,the diameter of tapped hole is M,depth is 2M.

3. The tangential tooth force in the form is the max tooth force,the nominal tangential tooth force is 1/2 of the max one.

4. “K” is addendum reduction coefficient.

The slewing bearing used by the forage straw silage machine generally has a small bearing capacity. Selecting an appropriate slewing bearing can make the equipment safer and more stable.

The motor or reducer drives the pinion to rotate, and the pinion drives the slewing bearing to rotate, so as to achieve the purpose of driving the upper end mechanism to rotate.

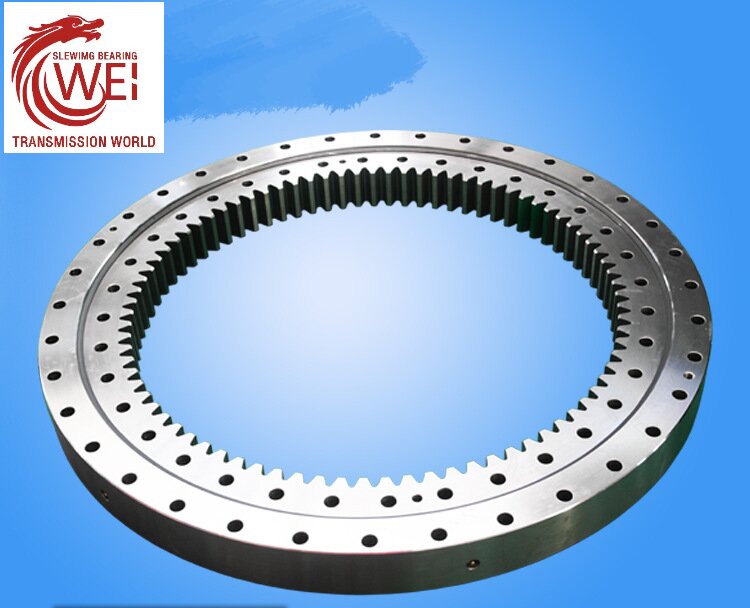

- Factory supply Inner gear slew bearing

2.Dust resistance,longer retention time

- Very competitive price for you to seize your customer!

Product Detail

Internal tooth slewing bearing single row ball 4-point contact 013 series

The inner and outer gears of the slewing ring are directly toothed on the inner or outer ring, and are processed by a gear hobbing machine or a gear shaper. If the working environment is loaded, it needs to be quenched. The internal gear slewing ring: the overall appearance is relatively neat, There is no need to install a safety cover at the meshing part of the gear and the slewing ring. The gear has better dust resistance, longer retention time by adding lubricant, and lower transmission contact stress of internal gear meshing, less wear and longer service life.

If it is an internal gear type, the outer gear ring should be fixed with bolts of appropriate strength grade. The bolts and nuts should meet the standards of GB3098.1 and GB3098.2. Then the pinion gears mesh with the inner teeth to drive the inner ring to rotate to achieve the purpose of transmission.

One of the most common applications is excavators. Generally, excavators need to use internal tooth slewing bearings, and the internal teeth need to be quenched to increase the hardness of the teeth.

FAQ :

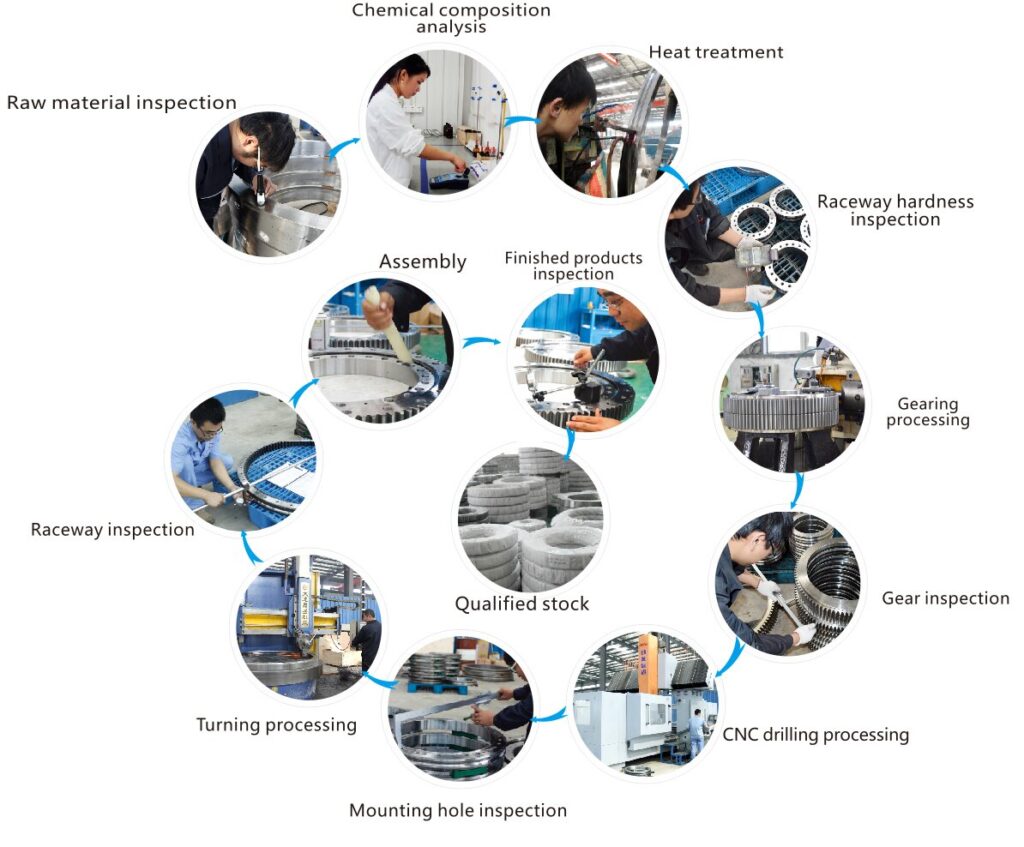

1 LW Slewing Bearing Heat Treatment

Heat Gear Slewing Bearings are in the majority of cases supplied with spur tooth. Stub teeth also is ok.There are two kinds of tooth hardening. They are normalizing and tempering, According to the different applications, there are two ways of quenching. They’re whole tooth quenching and single-tooth quenching. Single-tooth quenching can be divided into tooth surface & root quenching and tooth surface quenching.

2 . The Calculation of Slewing Bearing.

Static load capacity

The determined loads must be multiplied with a factor fstat allocated to the application. The product Fa’ or Mk’ must be below the static critical load curve of the selected bearing.

With regard to radial loads in load combinations

Fa = axial load

Fr = radial load

Mr = tilting moment

3 Protection Against Corrosion

We make Protection Against Corrosion on surface of bearing,and make couple of packing paper.

4.Customize.

Yes,we have professional technical terms.

5.Warranty:

General 1 year.

- Reliable reputation.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.