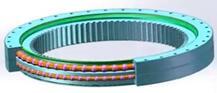

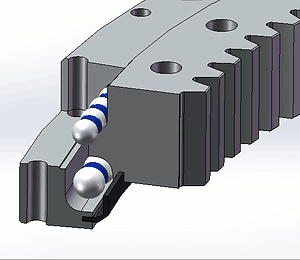

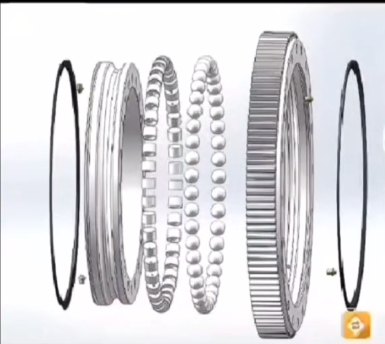

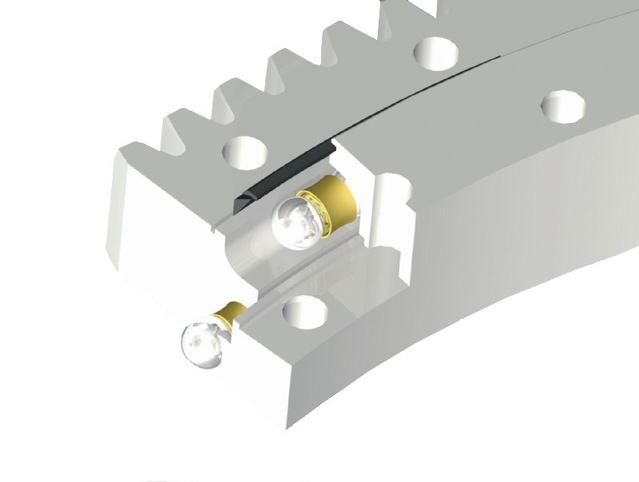

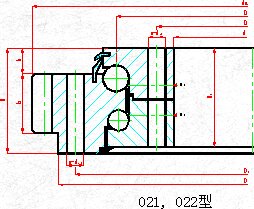

The double-row four-point contact ball slewing bearing structure is similar to the single-row ball slewing bearing, except that it uses two rows of steel balls as rolling elements, the two rows of steel balls have the same size, and a single isolation block is set between the steel balls. The inner and outer rings are integral, and the steel balls are inserted by plugging the holes. It is the first choice for the main engine with heavy load and limited radial structure size.

If you need heavy duty slewing bearing, we recommend you our Double-row ball slewing bearing.

They could bear huge axial loading and radial loading. It is especially suitable for heavy machinery requiring larger diameters.

Such as bucket wheel excavators and wheels type cranes, ship cranes, port cranes, molten steel running platforms and large-tonnage truck cranes and other machinery.

he double-row reducing ball double-row ball slewing bearing has three races. The steel balls and spacers can be directly discharged into the upper and lower raceways. According to the stress conditions, two rows of steel balls with different diameters are arranged. This kind of open assembly is very convenient. The load-bearing angle of the upper and lower arc raceways is 90°, which can bear great axial force and tilting moment. When the radial force is greater than 0.1 times the axial force, the raceway must be specially designed. The axial and radial dimensions of the double-row reducing ball slewing ring are relatively large and the structure is tight. It is especially suitable for loading and unloading machinery such as tower cranes and truck cranes that require medium or larger diameters.

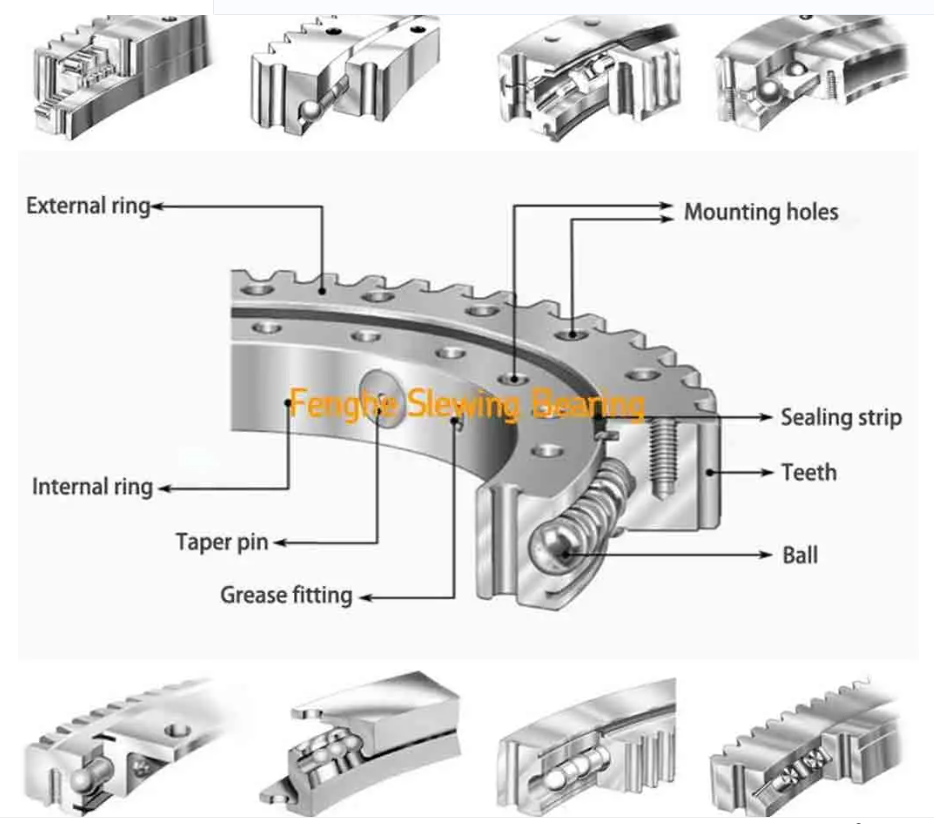

Turntable bearing, also known as slewing bearing, is a kind of large bearing which can bear large axial load, radial load and overturning moment at the same time. Turntable bearings are usually equipped with mounting holes, internal or external gears, lubricating oil holes and sealing devices, so that the main engine structure design is compact, the guide is reliable and the maintenance is convenient.

The main raw material of the slewing bearing is ring forgings, and the material is generally divided into 50Mn and 42CrMo. The process is generally divided into normalizing and quenching. In this way, the slewing bearing raw materials can

be divided into 50Mn normalizing material, 50Mn modified material, and 42CrMo positive material. Fire material,42CrMo conditioning material four kinds of combinations. In terms of cost, 50Mn is cheaper than 42CrMo, and the normalizing process is cheaper than the quenching process.

Our factory, longwei slewing bearing co.,ltd can produce both standard and non-standard products.

As meeting customers’ demand is our service principle.

We provide spot, generation processing, drawing processing, sample processing, free design and other services.

Slewing ring is a new type of mechanical parts that has gradually emerged in the world in the past 40 years. It consists of inner and outer rings, rolling elements, etc. At present, the slewing ring produced in my country is mainly designated by the Ministry of Machinery Industry in the early 1980s.

Small slewing ring bearing could be used in many area. Such as small turntables, small machine, and so on.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

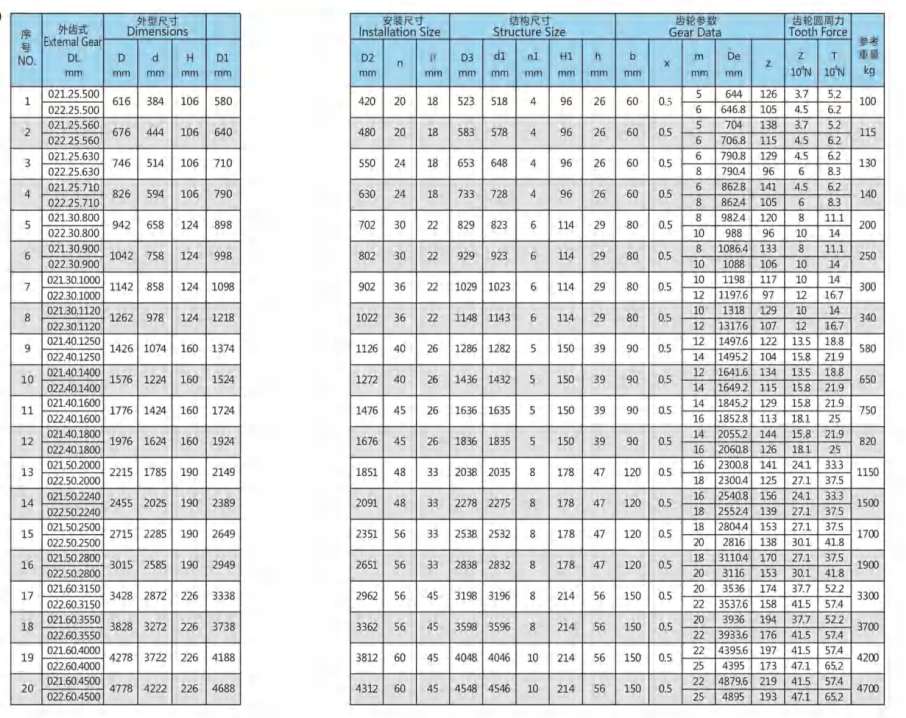

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.