Note

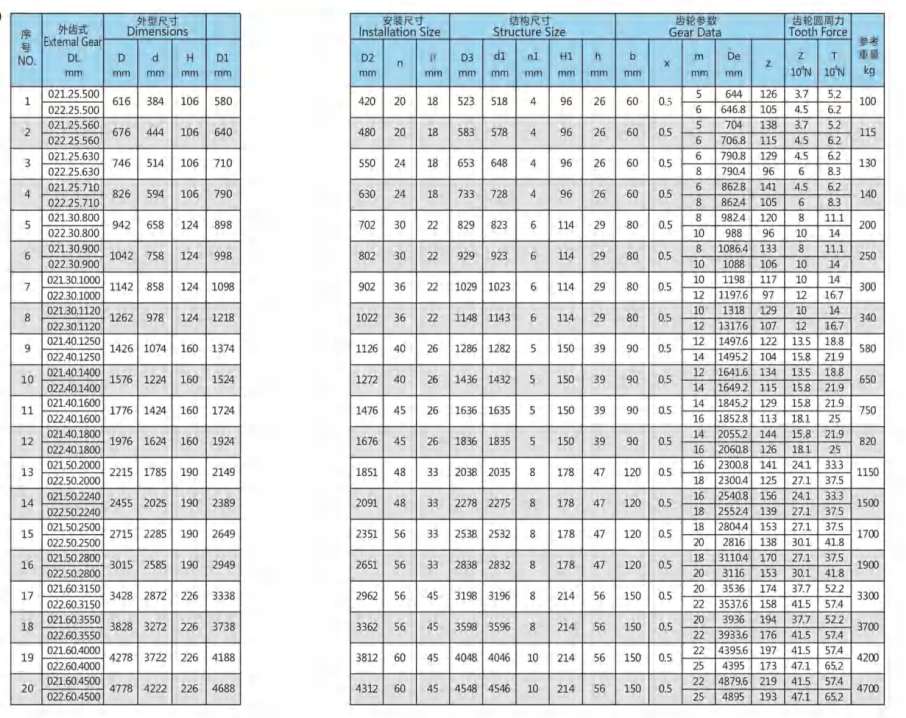

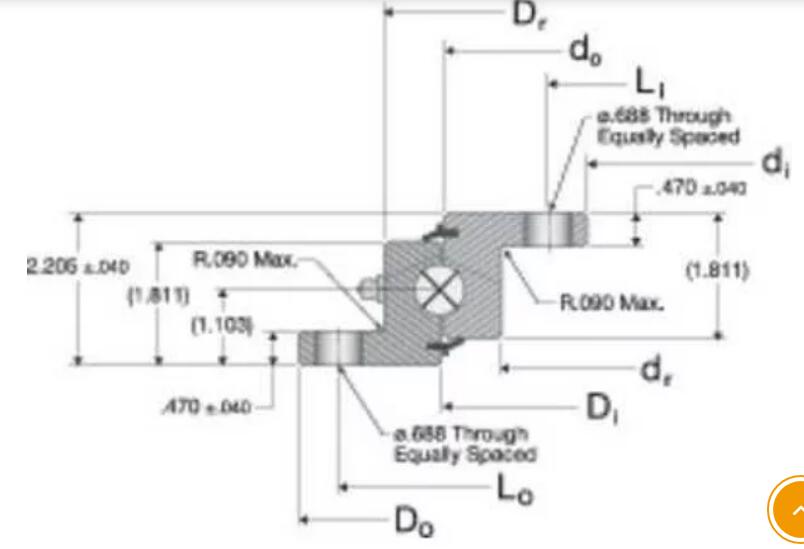

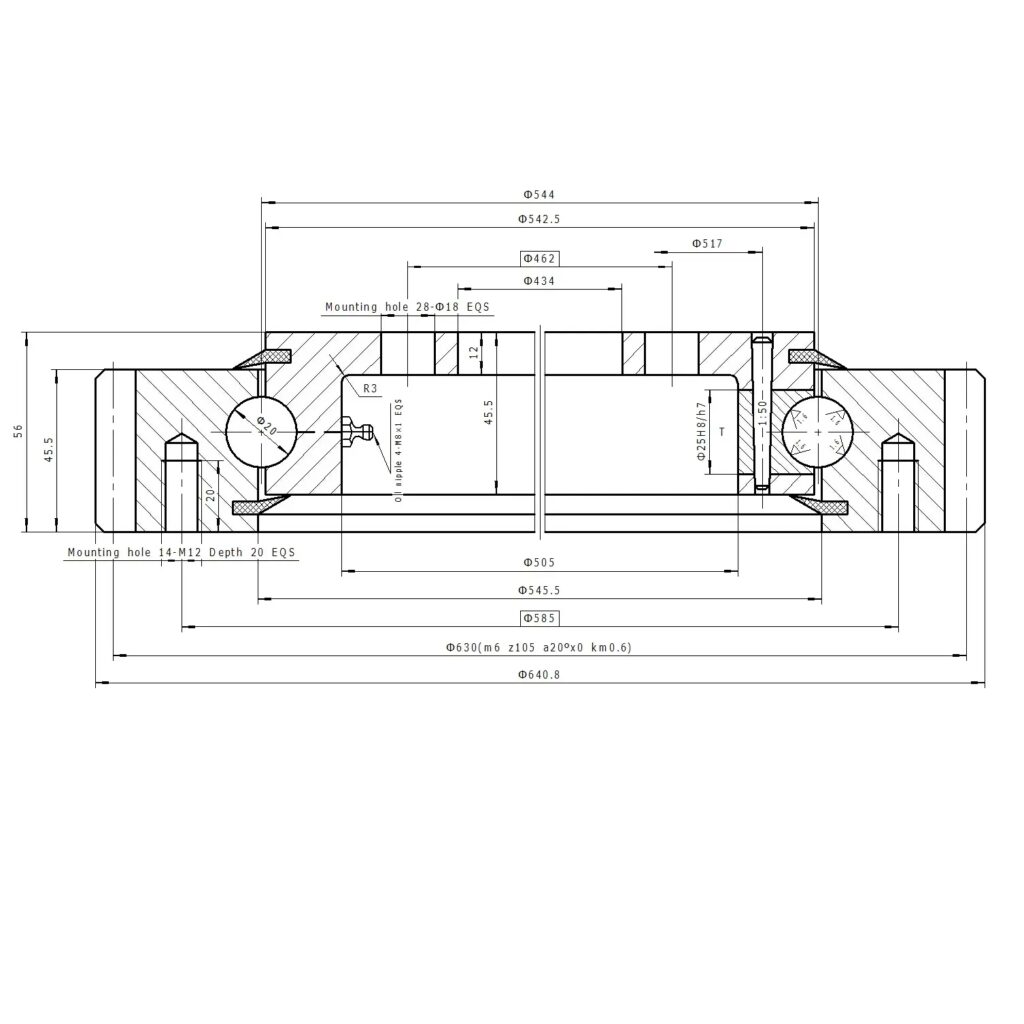

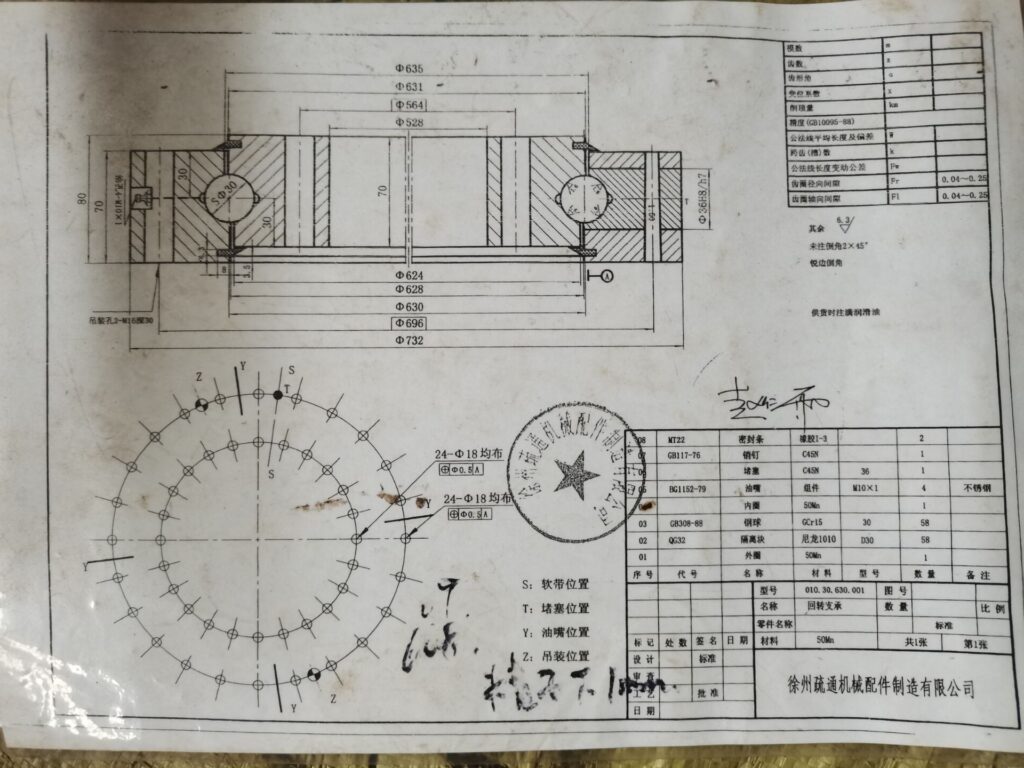

1. n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2.The Oil nipple’s location can be change according to the user’s application.

2. n-φcan change to tapped hole,the diameter of tapped hole is M,depth is 2M.

3. The tangential tooth force in the form is the max tooth force,the nominal tangential tooth force is 1/2 of the max one.

4. “K” is addendum reduction coefficient.

Gear accuracy level of slewing bearing

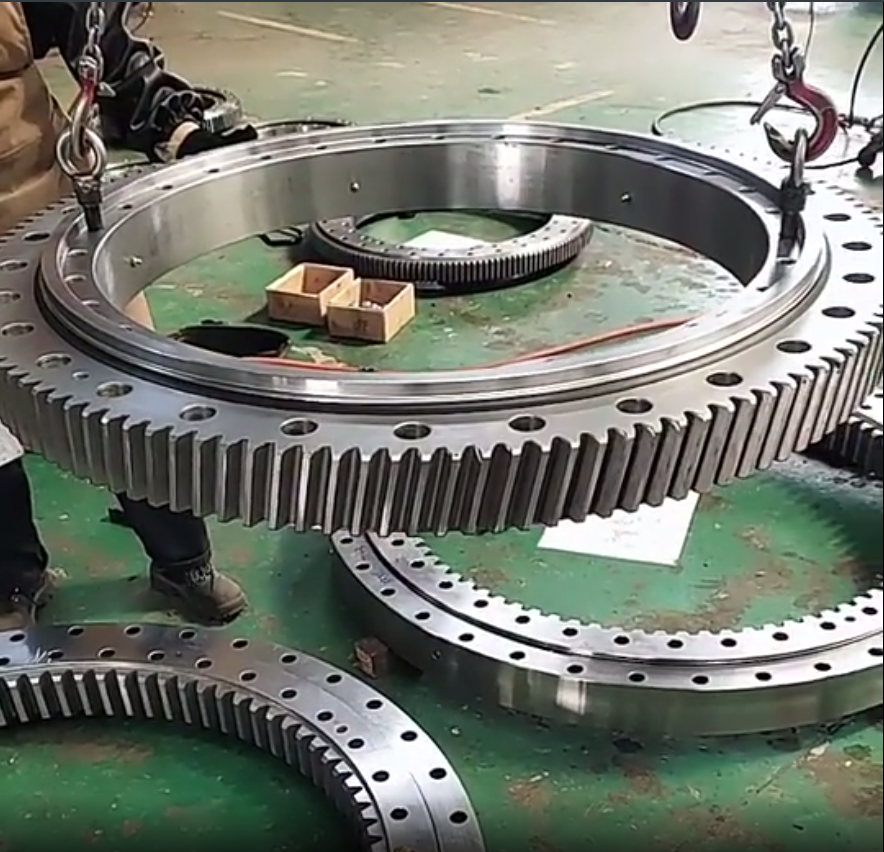

Slewing bearing its gear precision grade should be between 7 to 11, which determines the smoothness of the slewing bearing drive, load distribution uniformity and transmission accuracy. The higher the slewing bearing gear precision, the more intensive the mesh tooth surface contact spots, so that the noise value is reduced, the smoothness of operation improved.

The contact and bending strength of gears under ultimate and fatigue loads were calculated and verified according to ISO6336-1:2006, ISO6336-2:2006 and ISO6336-3:2006 respectively. Sf is 1.48 and the gear mesh clearance is adjusted for the highest point of radial run out of the slewing bearing gear pitch circle. The minimum tooth clearance is typically 0.03 to 0.04x modulus, and the gear mesh clearance of the pinion gears on the entire circumference needs to be re-checked after final fastening of the slewing bearing .

Single-row four-point contact ball slewing ring internal ball machining accuracy and internal raceway machining accuracy is not high, or there are quality defects and lack of lubricating oil in the raceway roller and spacer collision, directly affect the smooth operation of the slewing ring and noise, so when checking the slewing ring defects, sometimes by replacing the ball to reduce the frequency of failure.

Due to the gear under load after a long working time, there will be a small piece of metal or strip of metal near the pitch line, pitting or gnawing metal chips off, the formation of pitting or teeth. The slewing bearing tooth surface pitting with the increase in working time and expanding so that the slewing bearing mesh tooth damage, tower crane rotary noise and impact increases, the cycle of impact down the metal particles and accelerate the wear of the slewing ring tooth surface, forming a vicious cycle. In addition, the manufacturing and assembly of the starter motor in the slewing ring mechanism has its own defects to produce impact jitter, and the engagement process of the drive wheel with the slewing bearing is unstable, which also increases the frequency of jitter and reverberation noise decibels.

If the weld quality is not up to standard, the weld defect needs to be reworked and rewelded. In the repair welding repair will not only produce new welding stress and the flatness of the machined mounting surface will also have a great impact, at the same time the welding current generated in the slewing bearing through the internal rolling body and slewing ring raceway will also cause some damage. In addition, assembly errors in manufacturing assembly, field installation of the pin threading and bolt preload can also produce abnormal noise or chatter if the requirements are not met.

slewing ring main forms are external and internal type, the large and small gears mesh poorly, sometimes tight, sometimes loose, in the slewing ring tooth run out maximum position meshing too tight produce noise. So the manufacturing process is critical. Slewing bearing just left the factory in idling will issue a steel ball rolling uniform sound, which is normal. Such as in the uniform normal ringing accompanied by another abnormally large ringing is abnormal. There are many reasons for the failure.

FAQ

1: How to order?

Please refer to the help under the single payment.

2.What are the shipping methods?

Ocean shipment to the port close to your city; Air shipment to the airport close to your company; Door to door service by international express.

3.When can I get the price?

We usually quote within 12 hours after we get your inquiry. If urgent to get the price, please call us or tell us by email , we will regard your inquiry priority.

4.You are a trader or a manufacturer?

We are an industry and trade integration business, our factory located on Xuzhou City.

5.How about the payment terms?

We usually accept T/T or L/Cat sight . other terms also could be negotiated.

6.What is your minimum order?

It depends on what you are buying. Normally, our minimum order is 1pcs.

7.What is your delivery time?

If there are any parts in stock , our delivery time is only 3-7 days. If our standard model,the delivery time is around 25 days,if non-standard model,the delivery time is 38~45 days.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.