| Plane deviation of mounting bracket P (mm) | ||||

|---|---|---|---|---|

| Raceway center diameter | Plane deviation of mounting bracket P (mm) | |||

| DL(mm) | single row four ball | double row ball | cross roller | |

| ~1000 | 0.15 | 0.2 | 0.1 | |

| >1000~1500 | 0.19 | 0.25 | 0.12 | |

| >1500~2000 | 0.22 | 0.3 | 0.15 | |

| >2000~2500 | 0.25 | 0.35 | 0.17 | |

| >2500~4000 | 0.3 | 0.4 | 0.2 | |

| >4000~6000 | 0.4 | 0.5 | 0.3 | |

| >6000~8000 | 0.5 | 0.6 | 0.4 | |

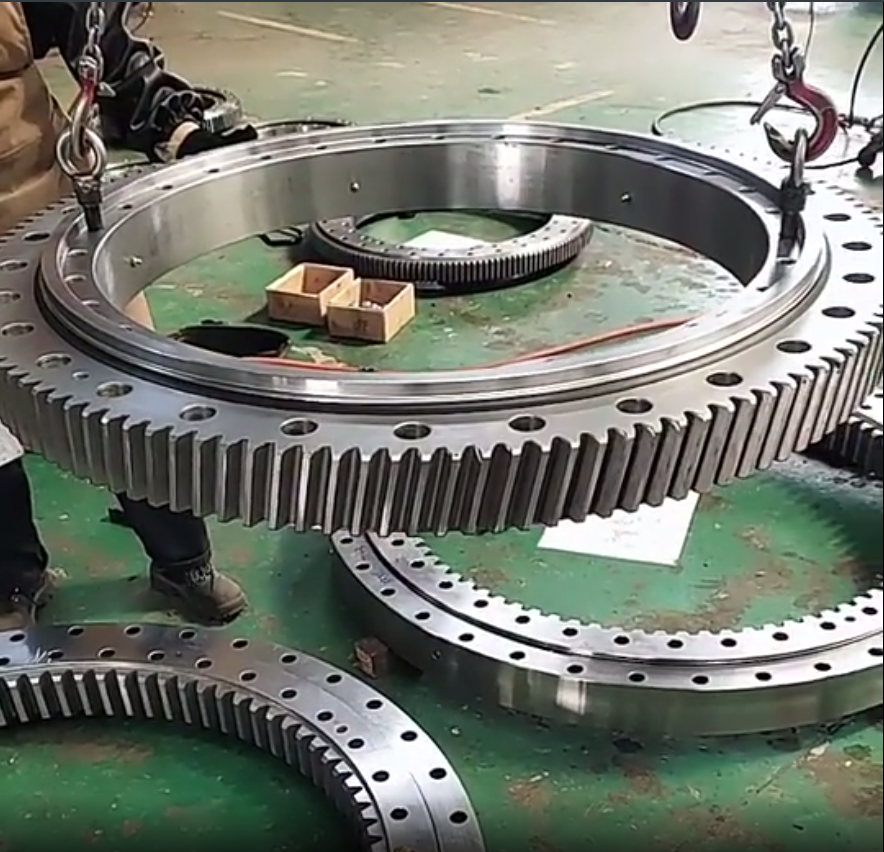

| Products discription | |||

|---|---|---|---|

| Model Number: | 132.40.1120 | Brand name | longwei |

| Production Experience | Since 2004 | Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory |

| Feature: | THREE ROW ROLLER | Gear Options: | Internal Gear |

| Material: | 50Mn/42CrMo/Customized | Seals Type: | Nitrile Rubber or as requirement |

| MOQ | 1 set | CERTIFICATE: | ISO9001:2008/SGS |

| Bore Diameter | 956 mm | Outside Diameter | 1284mm |

| Operating tempereature: | -30°C +70°C | Hardness: | 55-62HRC |

| Product Name: | Three row roller with internal Gear Slewing Bearing | Service: | OEM Service.Design Service |

| Net Weight : | 820kgs | Rolling element: | Roller & Spacer |

| Warranty Period | 1 year | Testing | In house or third party |

| MOQ | 1 SET | Size | Standard OR Customized |

| Height | 182 mm | H.S. Code | 848210900 |

| Packaging Details | 1.First lubricated, Second circled with plastic film,kraft paper,blue belt,then packaged inwooden case,last gathered in Wooden pallet.2 According to your requirements | Product Type: | Three Row Roller |

Our factory,longwei transmission slewing bearing co.,ltd can produce both standard and non-standard products. As meeting customers’ demand is our service principle.

We provide spot, generation processing, drawing processing, sample processing, free design and other services.

The company has complete research and development, verification and inspection equipment, and currently there are more than 20 kinds of equipments in the factory, including automatic turret microhardness tester, microcomputer-controlled universal testing machine, metallographic microscope, magnetic particle flaw detector, digital ultrasonic flaw detector, bearing measuring instrument, Leeb hardness tester, ultrasonic surface quenching layer thickness gauge, three coordinates, etc. A variety of testing and control methods are used to escort the manufacture of high-quality products.

FAQ

1.Are you a factory or a trading company?

.We are a manufacturer of slewing bearing and slewing drive with experience about 20 years.

2 .We have over 90 sets production machines, such as 4m CNC Raceway Quenching Machine,CNC integral tooth quenching machine,Gear Milling machine,5m Vertical Lathe etc.

3.What are your advantages compared with others?

a.Passed ISO9001:2015, CCS, SGS ,BV certificates;

b.Timely & dependable delivery, good quality and competitive price enable our company to maintain 30% increase on annual sales;

c.Patented slewing bearing and slewing drive.

d.Passed the Factory -Audit process and established cooperation with world-famous companies, such as XCMG , SANY, SUNWARD,TEREX etc.

4 ,How do you guarantee the delivery time?

We have strict production schedule and keep stock of material for standard models to ensure the delivery time.

25-30 days for standard model;

45-55 days for customized model.

Reviews

There are no reviews yet.