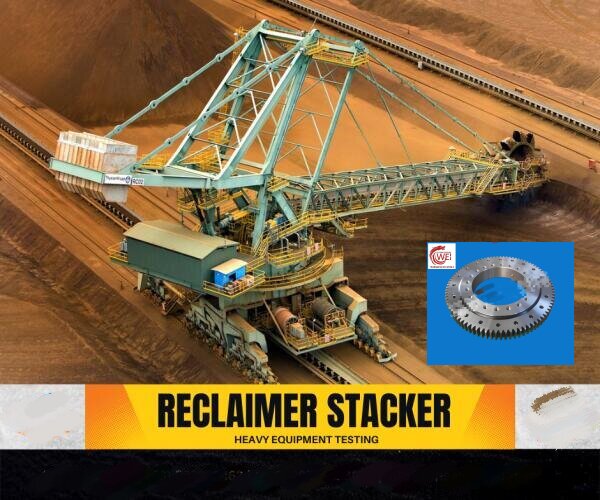

The use of continuous bucket wheel material, with the belt conveyor on the machine continuous stacking rail loading and unloading machinery. It is a special machine for bulk materials (bulk materials) storage yard, which is evolved on the basis of bucket wheel excavator. It can be used as a storage yard transportation mechanized system with unloading (ship) machine, belt conveyor and loading (car) unit. The production capacity can reach more than 10,000 tons per hour. The operation of bucket wheel stacker and retake machine has strong regularity and is easy to realize automation. The control mode includes manual, semi-automatic and automatic.

The boom type bucket wheel stacker is composed of bucket wheel mechanism, rotary mechanism, belt conveyor, tail car, pitching and running mechanism. The lifting slewing mechanism is composed of slewing support and driving device to make the boom turn around. In order to ensure that the bucket shovel can be filled when the boom is at any position, the rotation speed is required to realize automatic adjustment within the range of 0.01 ~ 0.2 RPM according to certain rules need use dc motor or hydraulic drive mostly.

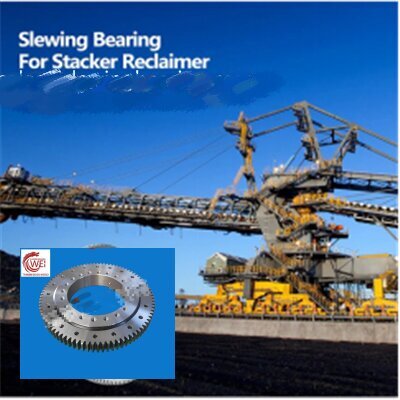

The slewing bearing used by the stacker and reclaimer is generally a heavy-duty slewing bearing, and the tail end bearing needs to carry a large axial force and overturning moment. The main function is to support and rotate, and to control the direction of the cantilever. The slewing bearing used for front-end stacking and reclaiming generally carries radial force or axial force and a certain overturning moment, and its main function is to rotate.

Selecting the appropriate slewing bearing can effectively increase the bearing capacity, prolong the service life, and ensure the smooth and efficient operation of the equipment.

The motor drives the pinion to rotate, generates radial torque through axial motion, drives the slewing bearing to rotate, and makes the platform or mechanism connected to the slewing bearing rotate with the slewing bearing.

The reclaimer is a lifting device for heaped material, which needs to be transported from a stockpile for further processing. The diverse selection of models ensures all kinds of storage locations are catered to. These can visually resemble bucket excavators. Since swivel movements have to be carried out to remove a stockpile, our slewing bearings of varied dimensions are also put to use here.

Three row roller slewing bearings are widely used on heavy-duty machines which demand large working radius.

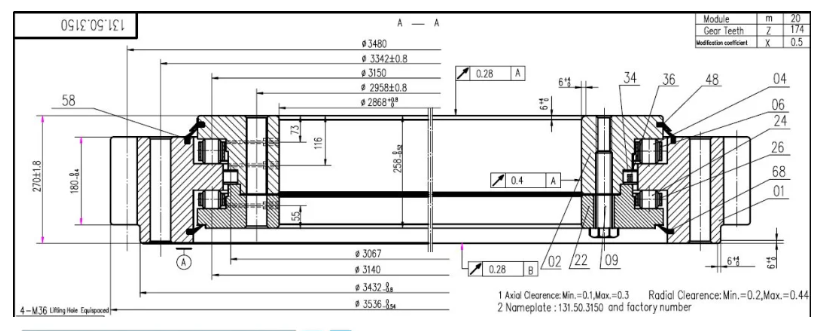

Product Detail

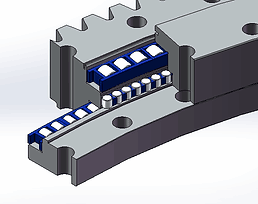

Three row roller slewing ring bearing has three seat-rings, which separate the upper, lower and radial raceway, via which the load of each row of the rollers may be specified. Thus it can carry different load simultaneously and its load capacity is the largest one of the four types.

- Structure:

Triple row roller slewing bearing has three different types:

no gear

external gear

internal gear

- Features

Triple row roller slewing bearings have following features:

Larger axial and radial dimension, compact structure

- Application

three row roller slewing bearings are widely used on heavy-duty machines which demand large working radius, such as bucket-wheel excavators, wheeled cranes, ship cranes, ladle turret, auto cranes etc.

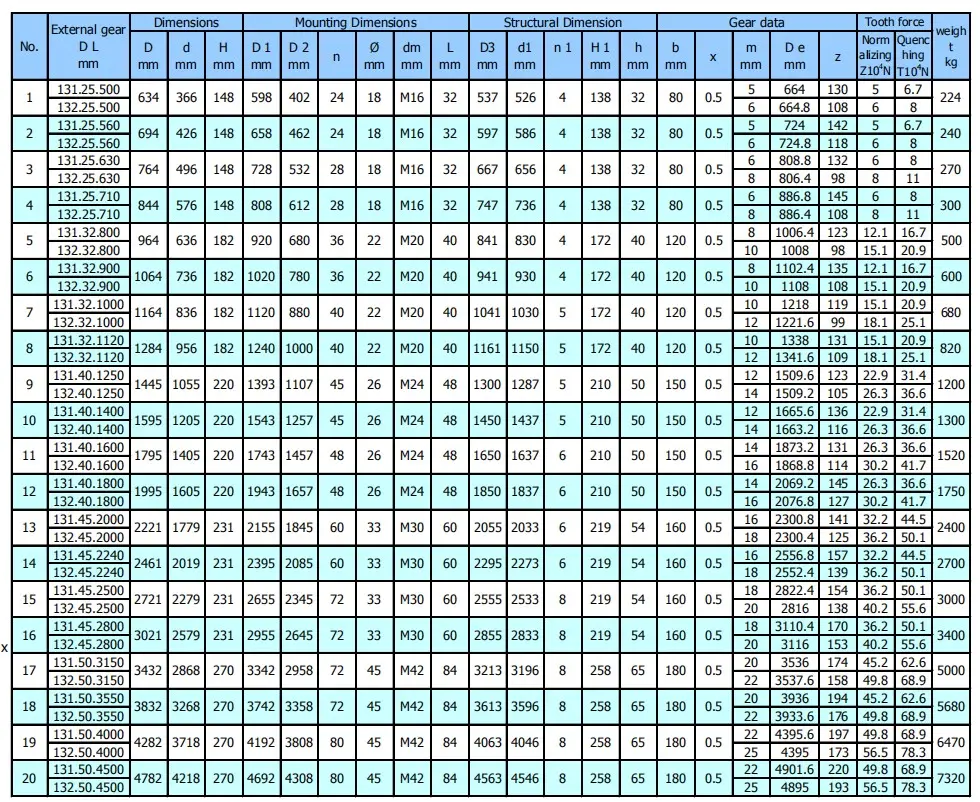

Attached is the catalogue for triple row roller slewing bearing, you can choose the suitable slewing bearing according to your demand.

Our advantages:

1.Fast delivery

2.Good quality and competitive price

3.Trial order accepted

4.ISO certified company

5.OEM

6. Custom-design is available.

7. We can do replacement slewing bearing for differenct type like Rothe Erde,Rollix,INA,SKF,IMO,TG,Kaydon etc.

Packaging&shipping

1.Filling with rust-proof oil

2.packing with protective layers

3.Fixed in the plywood

4.Packaging terms:Plywood case/ Pallet/Steel frame

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.