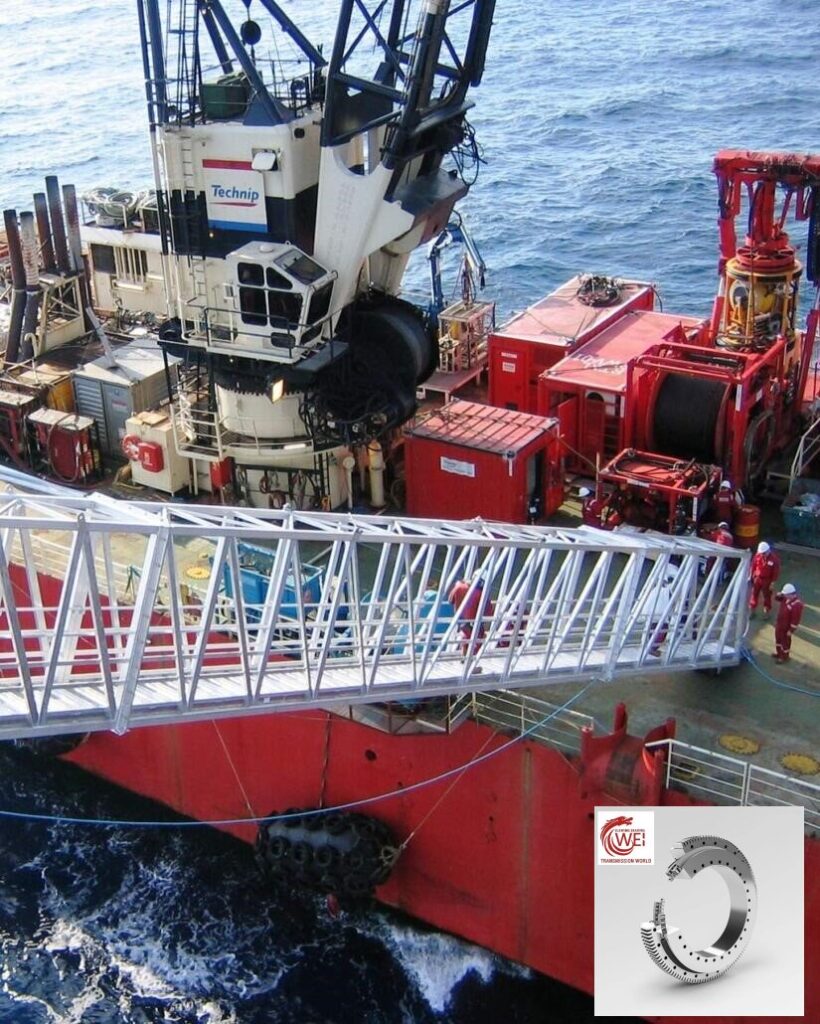

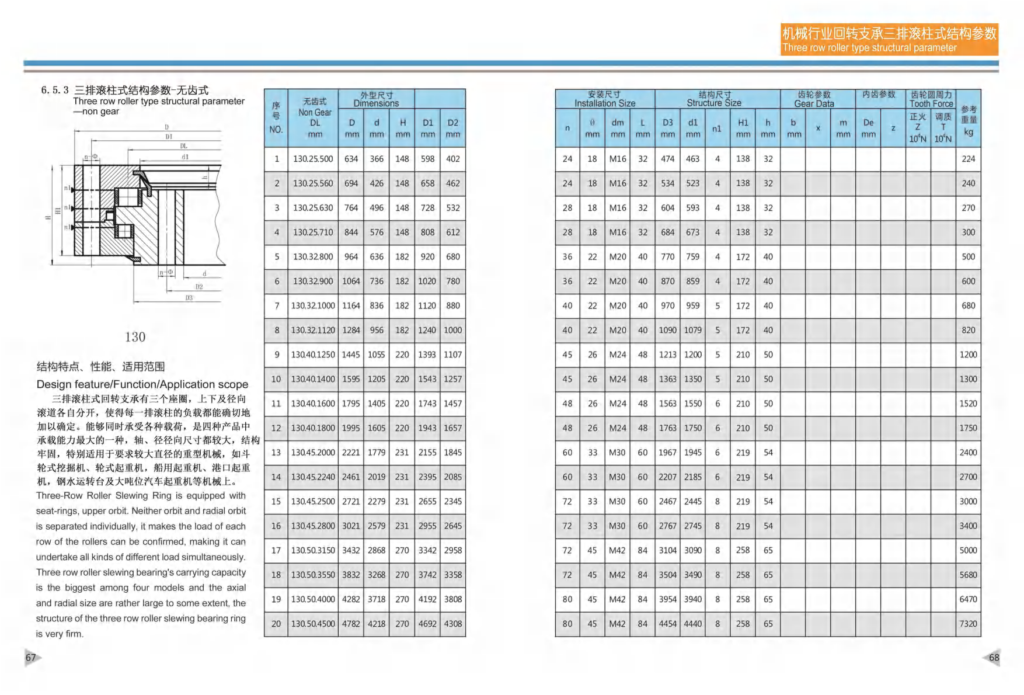

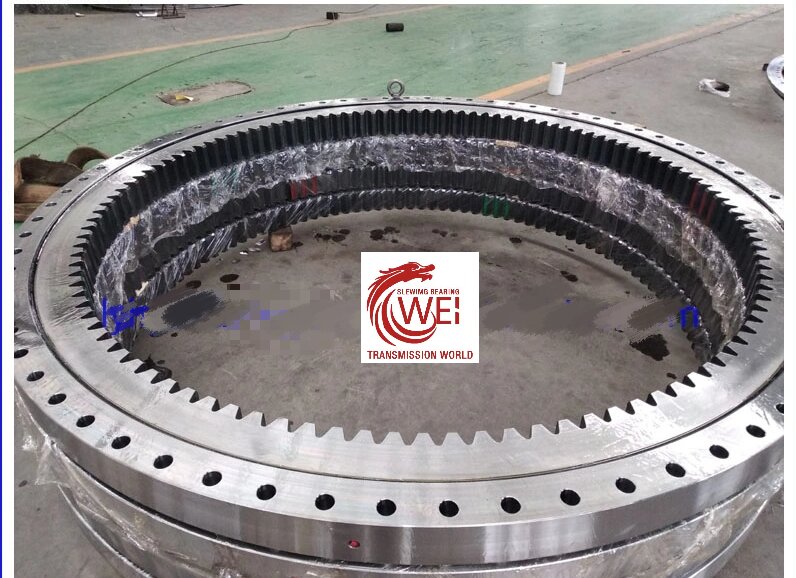

Three row roller type slewing bearing has three seat rings. The upper and lower raceways and radial raceways are separated respectively, so that the load of each row of rollers can be determined accurately. It can bear all kinds of loads at the same time. It is one of the four products with the largest bearing capacity. The shaft and radial dimensions are large and the structure is firm. It is especially suitable for heavy machinery requiring larger diameter, such as bucket wheel excavator, wheel crane, marine crane, port crane, steel water transport turntable and large tonnage truck crane.

Note

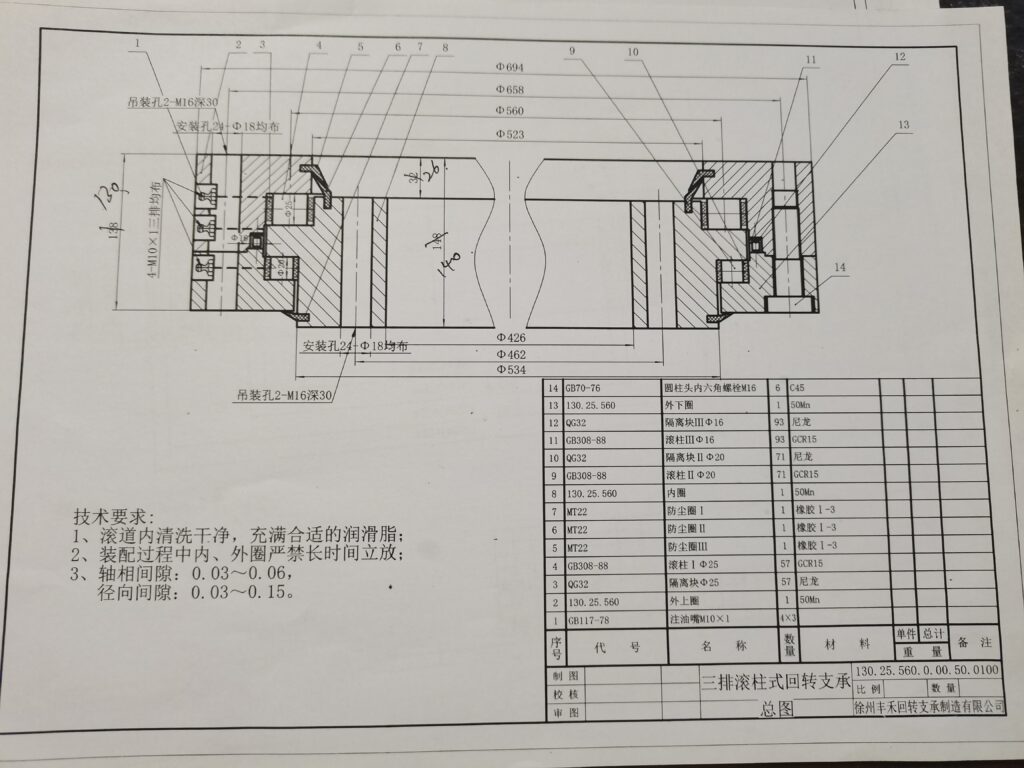

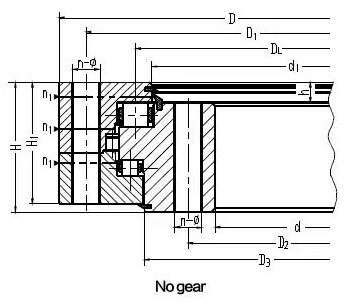

- n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2.The Oil nipple’s location can be change according to the user’s application.

2. n-φcan change to tapped hole,the diameter of tapped hole is M,depth is 2M.

3. The tangential tooth force in the form is the max tooth force,the nominal tangential tooth force is 1/2 of the max one.

4. “K” is addendum reduction coefficient.

Xuzhou XZWD Slewing Bearing Co.,Ltd. is a slewing bearing manufacturer specializing in standard and non-standard slewing bearing.Over the years, we supplied high quality product & good service to every user and gain good credit.We have strict quality control system in our own factory,meanwhile, we have passed ISO9001-2008

| Products discription | ||||

|---|---|---|---|---|

| Model Number: | 130.45.2240 | Brand name | longwei | |

| Production Experience | Since 2004 | Applicable Industries: | Onshore & Offshore Gangways and Bridges Tyne Gangway | |

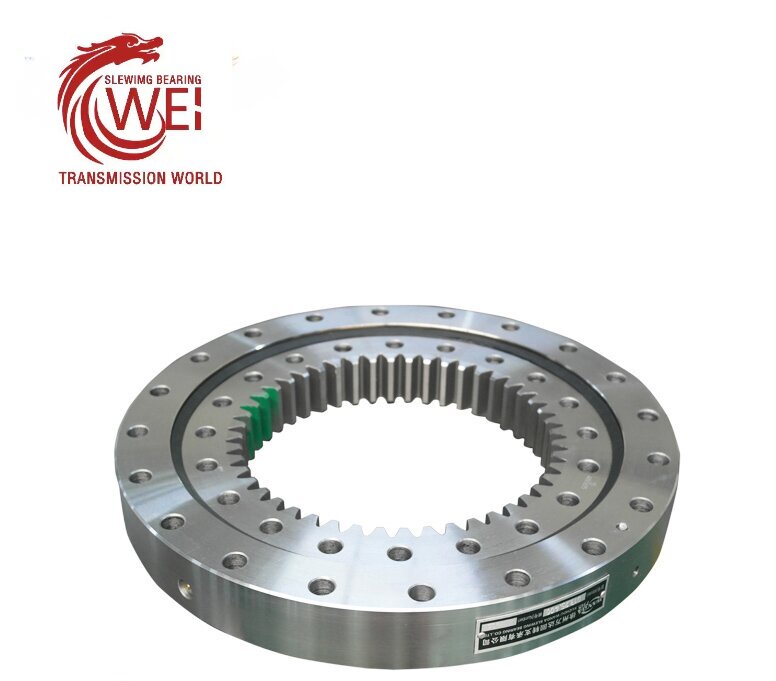

| Feature: | Multi-column, ROLLER | Gear Options: | Non Gear | |

| Material: | Bearing Steel/Customized | Seals Type: | Nitrile Rubber or as requirement | |

| Load Direction: | Axial Bearing | CERTIFICATE: | ISO9001:2008/SGS | |

| Bore Diameter | 2019 mm | Outside Diameter | 2461mm | |

| Operating tempereature: | -30°C +70°C | Hardness: | 55-62HRC | |

| Product Name: | Internal Gear Slewing Bearing 133.45.3150 | Service: | OEM Service.Design Service | |

| Net Weight : | 2700kgs | Rolling element: | Roller Bearings & Spacer | |

| Warranty Period | 1 year | Testing | In house or third party | |

| separated | Unseparated | Size | Standard OR Customized | |

| Height | 231 mm | H.S. Code | 848210900 | |

| Packaging Details | 1.Filling with rust-proof oil 2.packing with protective layers 3.Fixed in the plywood 4.Packaging terms:Plywood case/ Pallet/Steel frame | Product Type: | Three Row Roller | |

| Plane deviation of mounting bracket P (mm) | ||||

|---|---|---|---|---|

| Raceway center diameter | Plane deviation of mounting bracket P (mm) | |||

| DL(mm) | single row four ball | double row ball | cross roller | |

| ~1000 | 0.15 | 0.2 | 0.1 | |

| >1000~1500 | 0.19 | 0.25 | 0.12 | |

| >1500~2000 | 0.22 | 0.3 | 0.15 | |

| >2000~2500 | 0.25 | 0.35 | 0.17 | |

| >2500~4000 | 0.3 | 0.4 | 0.2 | |

| >4000~6000 | 0.4 | 0.5 | 0.3 | |

| >6000~8000 | 0.5 | 0.6 | 0.4 | |

Three row roller slewing bearing has three seat rings, upper and lower and radial raceways are separated respectively, so that the load of each row of rollers can be accurately determined and can bear various loads at the same time. It is one of the four products with the largest bearing capacity. The axial and radial dimensions are large and the structure is firm. It is especially suitable for heavy machinery requiring larger diameter, such as bucket wheel excavator and wheel type lifting machine Heavy machinery, marine crane, ladle slewing and large tonnage truck crane and other machinery.

Three row roller slewing bearing is an important transmission component. In order to achieve relative rotation, it needs to bear a lot of force during the operation. With the wide use of various mechanical equipment, three row roller slewing bearing is the most important part of the equipment. Essential accessories are widely used in various construction machinery, medical machinery and industrial equipment, and have been highly recognized. The external gear of light series slewing bearing is an essential product in three row roller slewing bearing. If the equipment is worn during operation, it can be lubricated between multiple parts to reduce friction and tear. It is better to stop the equipment and conduct detailed inspection to enhance the operation of the whole mechanical equipment. Meanwhile

is usually best to pay attention to the corrosion of the product to the corrosive product and take anti rust measures. Usually, clean the surface regularly and use the cleaning effect. It is better to keep the product surface dry at the same time, pay attention to the application of anti rust oil, if you encounter special circumstances, you can choose to use antirust oil. In fact, three row roller slewing bearing is a very good product. It is better not to touch it with hands when not in use, so as not to corrode the bracket.

Slewing bearing its gear precision grade should be between 7 to 11, which determines the smoothness of the slewing bearing drive, load distribution uniformity and transmission accuracy. The higher the slewing bearing gear precision, the more intensive the mesh tooth surface contact spots, so that the noise value is reduced, the smoothness of operation improved.

The contact and bending strength of gears under ultimate and fatigue loads were calculated and verified according to ISO6336-1:2006, ISO6336-2:2006 and ISO6336-3:2006 respectively. Sf is 1.48 and the gear mesh clearance is adjusted for the highest point of radial run out of the slewing gearing gear pitch circle. The minimum tooth clearance is typically 0.03 to 0.04x modulus, and the gear mesh clearance of the pinion gears on the entire circumference needs to be re-checked after final fastening of the slewing bearing .

Slewing bearing its gear precision grade should be between 7 to 11, which determines the smoothness of the slewing bearing drive, load distribution uniformity and transmission accuracy. The higher the slewing bearing gear precision, the more intensive the mesh tooth surface contact spots, so that the noise value is reduced, the smoothness of operation improved.

The contact and bending strength of gears under ultimate and fatigue loads were calculated and verified according to ISO6336-1:2006, ISO6336-2:2006 and ISO6336-3:2006 respectively. Sf is 1.48 and the gear mesh clearance is adjusted for the highest point of radial run out of the

The contact and bending strength of gears under ultimate and fatigue loads were calculated and verified according to ISO6336-1:2006, ISO6336-2:2006 and ISO6336-3:2006 respectively. Sf is 1.48 and the gear mesh clearance is adjusted for the highest point of radial run out of the slewing bearing gear pitch circle. The minimum tooth clearance is typically 0.03 to 0.04x modulus, and the gear mesh clearance of the pinion gears on the entire circumference needs to be re-checked after final fastening of the slewing bearing gear pitch circle. The minimum tooth clearance is typically 0.03 to 0.04x modulus, and the gear mesh clearance of the pinion gears on the entire circumference needs to be re-checked after final fastening of the

The contact and bending strength of gears under ultimate and fatigue loads were calculated and verified according to ISO6336-1:2006, ISO6336-2:2006 and ISO6336-3:2006 respectively. Sf is 1.48 and the gear mesh clearance is adjusted for the highest point of radial run out of the slewing bearing gear pitch circle. The minimum tooth clearance is typically 0.03 to 0.04x modulus, and the gear mesh clearance of the pinion gears on the entire circumference needs to be re-checked after final fastening of theslewing bearing .

If the weld quality is not up to standard, the weld defect needs to be reworked and rewelded. In the repair welding repair will not only produce new welding stress and the flatness of the machined mounting surface will also have a great impact, at the same time the welding current generated in the slewing bearing through the internal rolling body and slewing ring raceway will also cause some damage. In addition, assembly errors in manufacturing assembly, field installation of the pin threading and bolt preload can also produce abnormal noise or chatter if the requirements are not met.

slewing ring main forms are external and internal type, the large and small gears mesh poorly, sometimes tight, sometimes loose, in the slewing ring tooth run out maximum position meshing too tight produce noise. So the manufacturing process is critical. Slewing bearing just left the factory in idling will issue a steel ball rolling uniform sound, which is normal. Such as in the uniform normal ringing accompanied by another abnormally large ringing is abnormal. There are many reasons for the failure.

FAQ :

1 LW Slewing Bearing Heat Treatment

Heat Gear Slewing Bearings are in the majority of cases supplied with spur tooth. Stub teeth also is ok.There are two kinds of tooth hardening. They are normalizing and tempering, According to the different applications, there are two ways of quenching. They’re whole tooth quenching and single-tooth quenching. Single-tooth quenching can be divided into tooth surface & root quenching and tooth surface quenching.

2 . The Calculation of Slewing Bearing.

Static load capacity

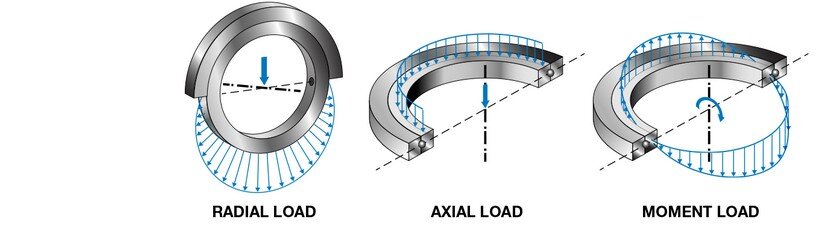

The determined loads must be multiplied with a factor fstat allocated to the application. The product Fa’ or Mk’ must be below the static critical load curve of the selected bearing.

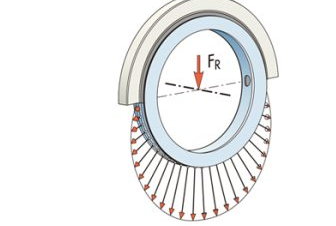

With regard to radial loads in load combinations

Fa = axial load

Fr = radial load

Mr = tilting moment

3 Protection Against Corrosion

We make Protection Against Corrosion on surface of bearing,and make couple of packing paper.

4.Customize.

Yes,we have professional technical terms.

5.Warranty:

General 1 year.

- Reliable reputation.

Reviews

There are no reviews yet.