| Products discription | |||||

|---|---|---|---|---|---|

| Model Number: | 111.20.355 | Brand name | longwei | ||

| Production Experience | Since 2004 | Applicable Industries: | Military,Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Energy & Mining, Food & Beverage Shops | ||

| Feature: | Single Row Crossed Roller | Gear Options: | Internal Gear Only | ||

| Material: | 50Mn/Customized | Seals Type: | NBR or as requirement | ||

| MOQ | 1 set | CERTIFICATE: | ISO9001:2008/SGS | ||

| Bore Diameter | 265 mm | Outside Diameter | 448mm | ||

| Operating tempereature: | -30°C +70°C | Hardness: | 207-262HB | ||

| Product Name: | High Precision Single Row Crossed Roller Internal Gear Slewing Ring | Service: | OEM Service.Design Service | ||

| Net Weight : | 55kgs | Rolling element: | Roller & Spacer | ||

| Warranty Period | 1 year | Testing | In house or third party | ||

| Key Word | High Precision Small Diameter Slewing Bearing | Size | Standard OR Customized | ||

| Height | 65mm | H.S. Code | 848210900 | ||

| Packaging Details | 1.Filling with rust-proof oil 2.packing with protective layers 3.Fixed in the plywood 4.Packaging terms:Plywood case/ Pallet/Steel frame | Product Type: | Single Row Crossed Roller |

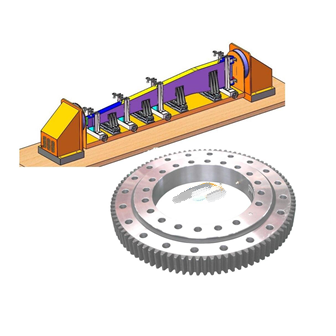

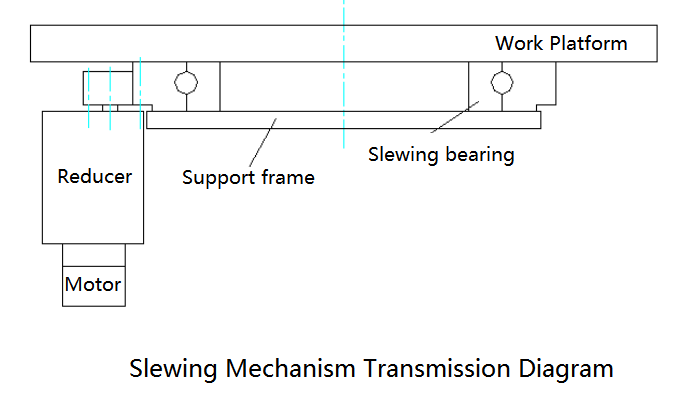

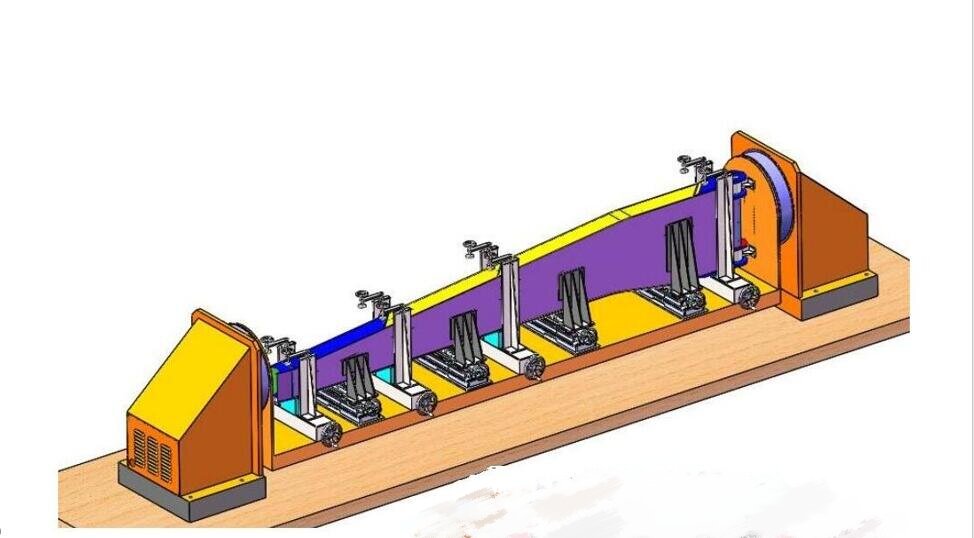

The positioner is mainly composed of a worktable, a slewing mechanism, a turning mechanism, a conductive device, a frame and an electric control box. The positioner is a special welding auxiliary equipment, which is suitable for the welding position of the slewing work to obtain the ideal processing position and the welding speed, can be used in conjunction with the operating machine and the welding machine to form an automatic welding center, and it can also be used for the displacement of the workpiece during manual operation .

The worktable rotation adopts frequency converter stepless speed regulation with high speed regulation accuracy. The remote control box can realize remote operation of the worktable, and can also be connected with the operating machine and the welding machine control system to realize linkage operation. The welding positioner is generally composed of a worktable rotating mechanism and a turning mechanism. Through the lifting, turning and rotating of the worktable, the workpiece fixed on the worktable can reach the required welding and assembly angles. The worktable rotation is frequency conversion stepless speed regulation. Satisfactory welding speed can be obtained.

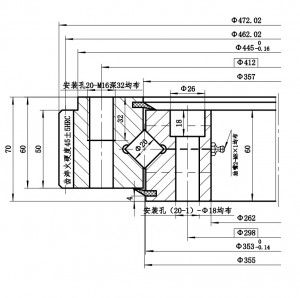

Slewing bearings for positioners generally require high-precision products with small clearances. Our company’s Single row cross roller slewing ring bearing 111 series can meet this application very well. Generally use 111.20.315 or 111.20.355. Please see the below drawing.

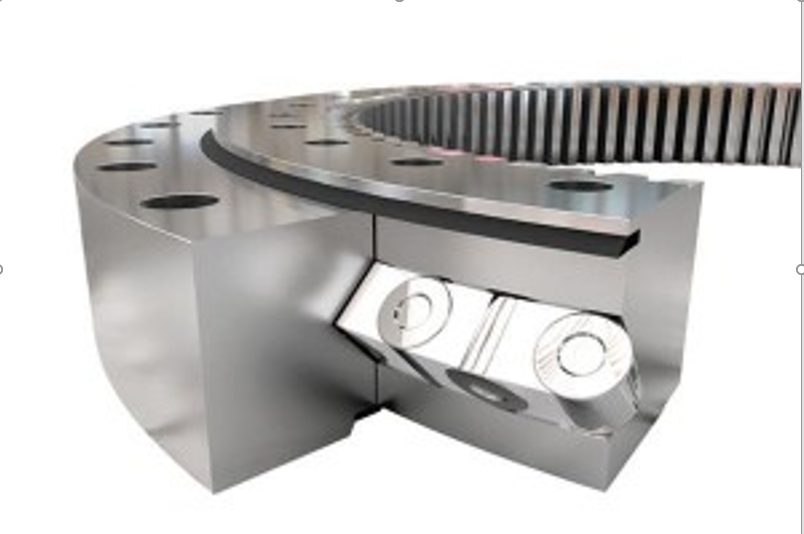

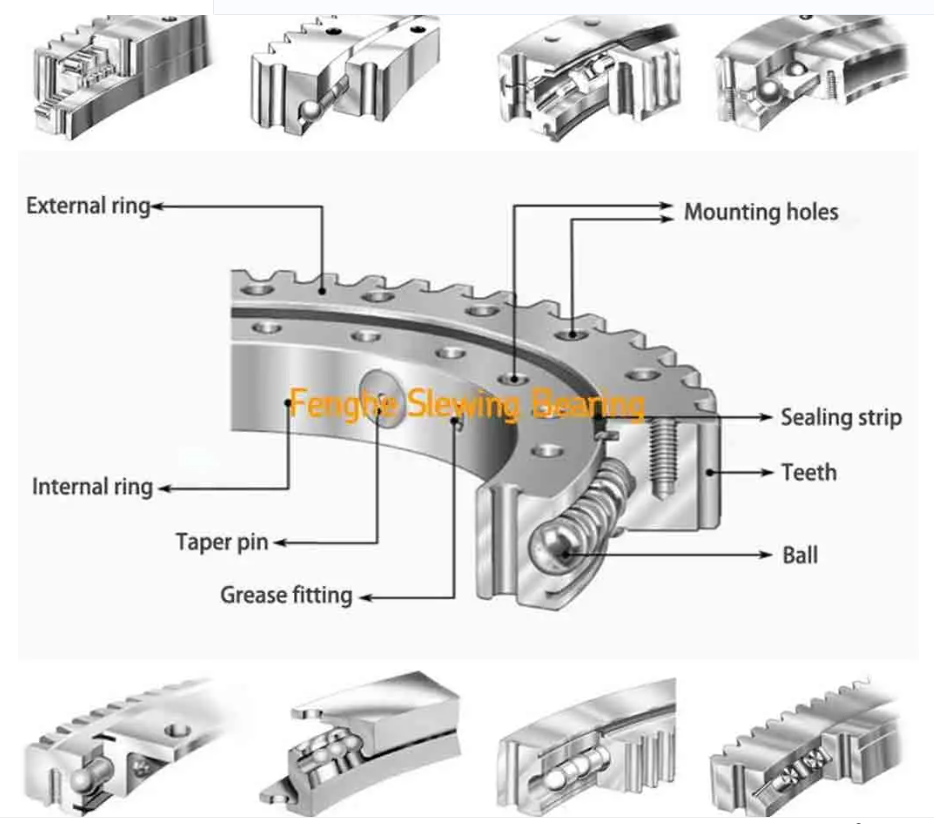

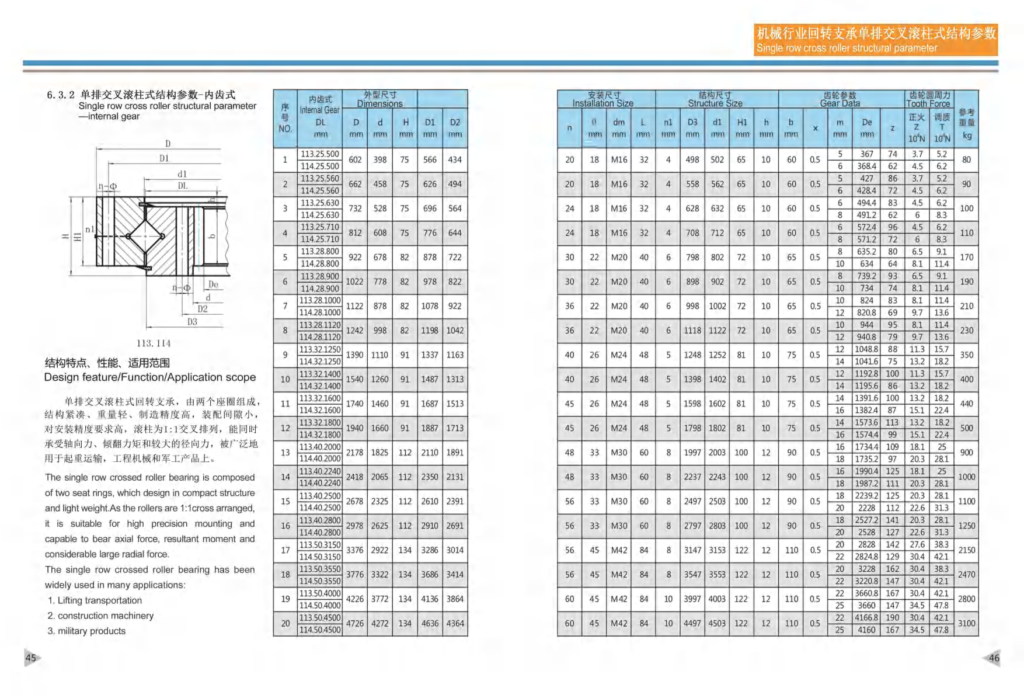

The single row crossed roller bearing is composed of two seat rings, which design in compact structure and light weight; this single row crossed roller type slewing bearing has the steel roller for the rolling element, not for the steel ball. As the rollers are 1:1cross arranged, it is suitable for high precision mounting and capable to bear axial force, resultant moment and considerable large radial force. The axial and radial clearance is smaller than single row ball slewing bearing. The rotating is not so flexible as the one row ball bearings, usually it use for some higher precision applications.

Our single row crossed roller slewing bearing ring’s axial and radial clearance’s precision is high.

Single row crossed roller ring bearings are mainly made of 50 Mn, 42CrMo and C45.

The single row crossed roller bearing has been widely used in many applications:

Note:

- N1 is the numbers of lubricating holes. Oil cup M10×1JB/T7940.1~JB/T7940.

2.The Oil nipple’s location can be change according to the user’s application.

- n-φ can change to tapped hole, the diameter of tapped hole is M, and depth is 2M.

- The tangential tooth force in the form is the max tooth force; the nominal tangential tooth force is 1/2 of the max one.

- “K” is addendum reduction coefficient.

Our advantages:

- Germany technology and made-in-China with good quality and competitive price;

- Rich experience in OEM and ODM;

- stable and fast delivery;

- prompt and responsible after-sales service;

- Certified by ISO9001:2008, SGS, CCS and BV.

Packaging&shipping

1.Filling with rust-proof oil

2.packing with protective layers

3.Fixed in the plywood

4.Packaging terms:Plywood case/ Pallet/Steel frame

Reviews

There are no reviews yet.