Construction machinery is the initial application field of slewing bearings and is also widely used ground treatment machinery, such as impact reverse circulation drilling rig, rotary drilling rig, impact rotary drilling rig, rotary drilling rig, reverse circulation rotary drilling rig, positive circulation rotary drilling rig, long spiral engineering drilling rig, diving engineering drilling rig, static pressure pile machine, pile drive

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

6.Flange type slewing bearing teeth type

–external gear slewing bearing

–internal gear slewing bearing

–Non-gear slewing bearing

| products discription | |||

|---|---|---|---|

| Model Number: | 061.25.1644 | Brand name | longwei |

| Production Experience | Since 2004 | Applicable Industries: | construction machinery, cranes,shipyard crane |

| Rolling-Element Number | single row four point contact ball slewing bearing | Gear Options: | with External gear |

| Material | 50Mn/42CrMo/ Customized | Sealing Glan | Sealed On Both Sides(NBR or As requirement) |

| Precision | P0. P6. P5 | CERTIFICATE: | ISO9001:2008/SGS |

| Bore Diameter | 1536 mm | Outside Diameter | 1791mm |

| Roller Type | Deep Groove Raceway | Forging hardness: | Hb229-269 |

| Products Name | single row four point contact ball slewing bearing, ring bearing, slewing gear | Service: | OEM Service.Design Service |

| Net Weight : | 237kgs | Material of Rolling element: | GCR15 |

| Warranty Period | 1 year | Testing | In house or third party |

| Origin | CHINA | Size | Standard OR Customized |

| Height | 68MM | H.S. Code | 848210900 |

| Transport Package | 1. Industrial Neutral Packing 2. Package as your requirements.3. Small size Bearings:Plastic vacuum packaging bag+Paper Box/Neutral Carton 4.Large size Bearings:Plastic film+pergamyn paper+Roll tape+Wooden Box | MOQ | 1 SET |

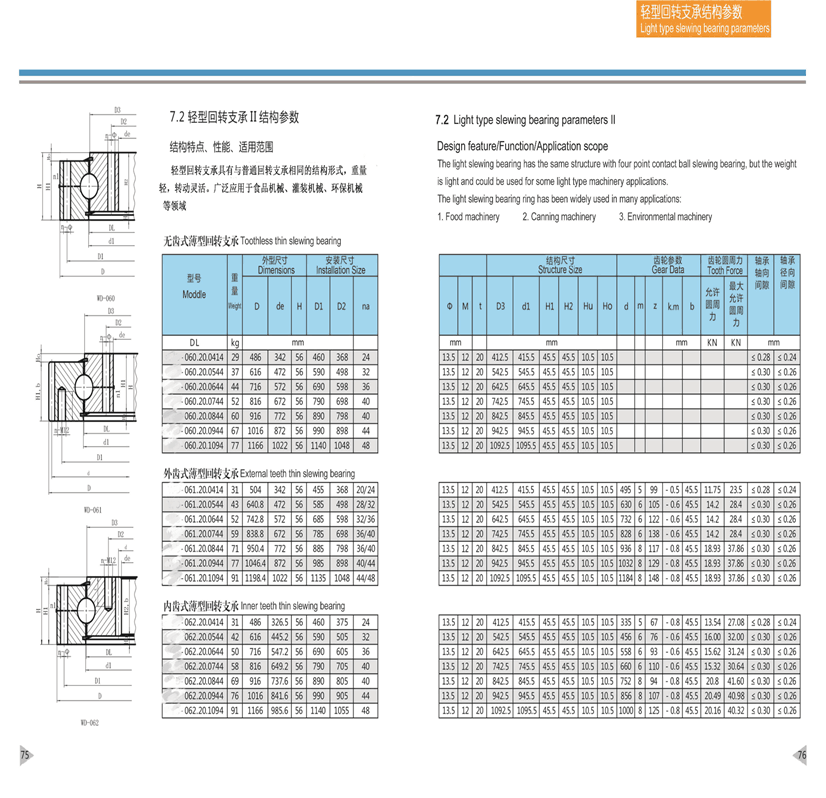

Flanged type Slewing Bearing

Flanged type slewing bearing has the same structure with four points contact ball slewing bearing, but the weight is lighter; the outer or inner ring of the flanged slewing bearing has the “L” edge, like a flange, that’s why we called it flange type bearing. Flange light slewing bearing ring is also used for some applications which has weight limit for the bearing, the weight for the flange type slewing ring is much lower than normal type. The materials of the flange slewing ring are mainly 50Mn, 42CrMo and C45.

| Plane deviation of mounting bracket P (mm) | ||||

|---|---|---|---|---|

| Raceway center diameter | Plane deviation of mounting bracket P (mm) | |||

| DL(mm) | single row four ball | double row ball | cross roller | |

| ~1000 | 0.15 | 0.2 | 0.1 | |

| >1000~1500 | 0.19 | 0.25 | 0.12 | |

| >1500~2000 | 0.22 | 0.3 | 0.15 | |

| >2000~2500 | 0.25 | 0.35 | 0.17 | |

| >2500~4000 | 0.3 | 0.4 | 0.2 | |

| >4000~6000 | 0.4 | 0.5 | 0.3 | |

| >6000~8000 | 0.5 | 0.6 | 0.4 | |

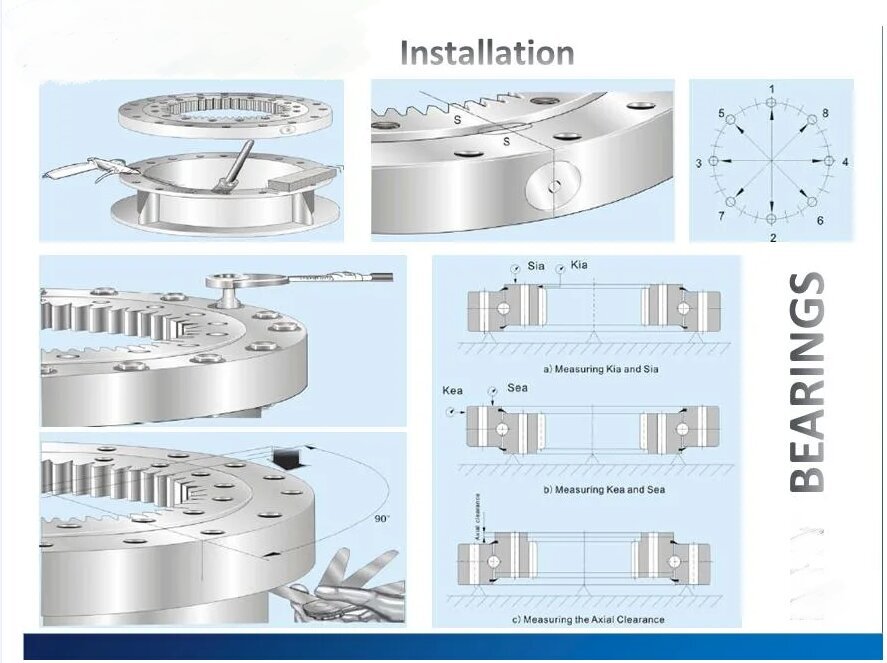

INSTALLATION OF Longwei transmission SLEWING BEARINGS

Preparation:

Make sure that the model is correct and slewing bearing isn’t damaged during transportation.

2. Check the appearance and rotational state of the bearing, such as rotational precision clearance, rotating flexibility, seals position, lubrication grease etc.

3. The installation datum plane and bracket installing plane should be clean, grease, burr, paint and other foreign body should be wiped off.

Installation:

1. The screws in the installing plane should be fit with the mounting holes in the slewing bearing

2. The slewing bearing has a soft zone marked with an “s” on the upper surface, when installing the bearing, it is important to ensure that this area is placed in a non-load or infrequent load zone.

3. When the bearing is placed on the supporting frame work it is important to check the interface between these two surfaces. This check should be carried out with the insertion of feel gauges between the two surfaces. If a gap should exist then it is recommended to plane/resurface the effective area so as to remove the gap.

4. Install slewing bearing with high strength screws, and choose appropriate strength bolts. All bolts are required to be tightened evenly. The sequence of this tightening process is shown in Pic. Welding of bearing is not allowed, in the event of welding any adjacent parts, heat transfer shall be avoided so as to cause the bearing to become deformed or change the hardness.

5. After installation, the bearing should be rotated to check for smooth operation and any emission of unusual noise. If either of the aforementioned are noted, then the bearing should be adjusted to eliminate them. The teeth of the largest run-out are coated with green paint.

FAQ:

Q: Are Longwei transmission slewing bearings trading company or manufacturer?

A: Longwei transmission slewing bearings is a professional manufacturer for slewing bearings, thin section bearings, ball bearings and rolling bearings

Q: How do Longwei Transmission Slewing Bearing control quality of their bearing?

A: Longwei transmission slewing bearings has established strict quality control systems, all the products and services has passed ISO9001-2008 Quality Certificate and third party such as CCS, LR,ABS,BV

Q: What is the MOQ?

A: MOQ is 1pc, pls message us for detailed information.

Q: How about the package for Longwei Transmission Slewing Bearing?

A: Standard Industrial packing in general condition (Plastic tube+ professional plastic belts+ plywood case). Accept design package when OEM.

Q: How long is the production time?

A: It takes about 7-40 days, depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have your own forwarder.

Q: Is sample available?

Reviews

There are no reviews yet.