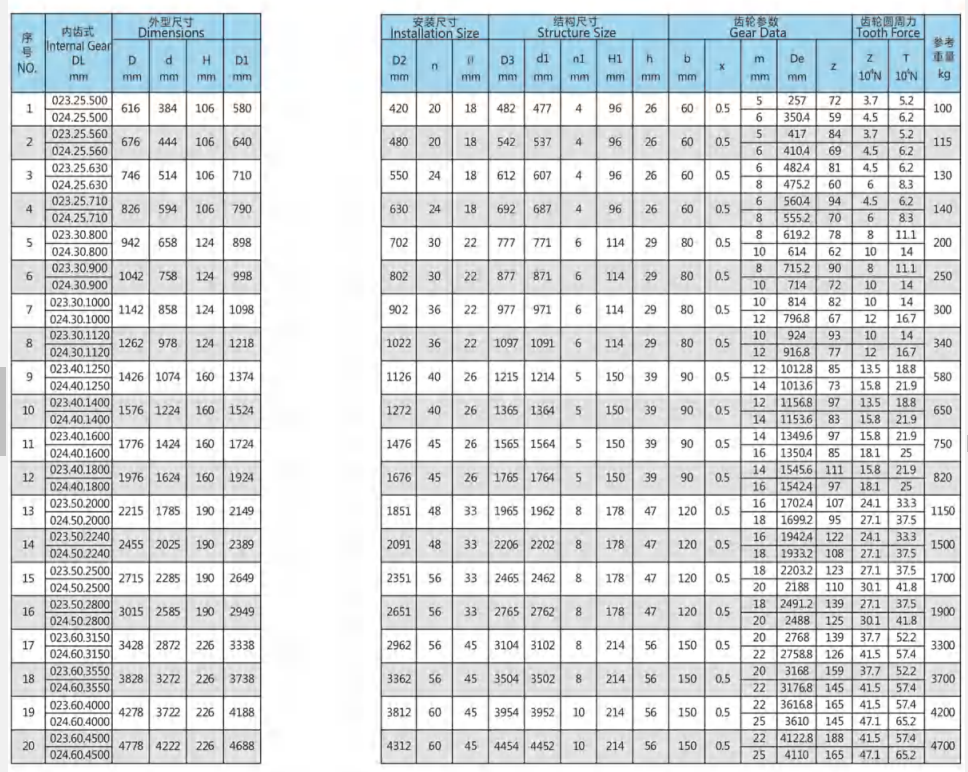

| Products discription | ||||

|---|---|---|---|---|

| Model Number: | 023.30.900 | Brand name | longwei | |

| Production Experience | Since 2004 | Applicable Industries: | Military,Building Material Shops, Construction works ,Energy & Mining, Food & Beverag | |

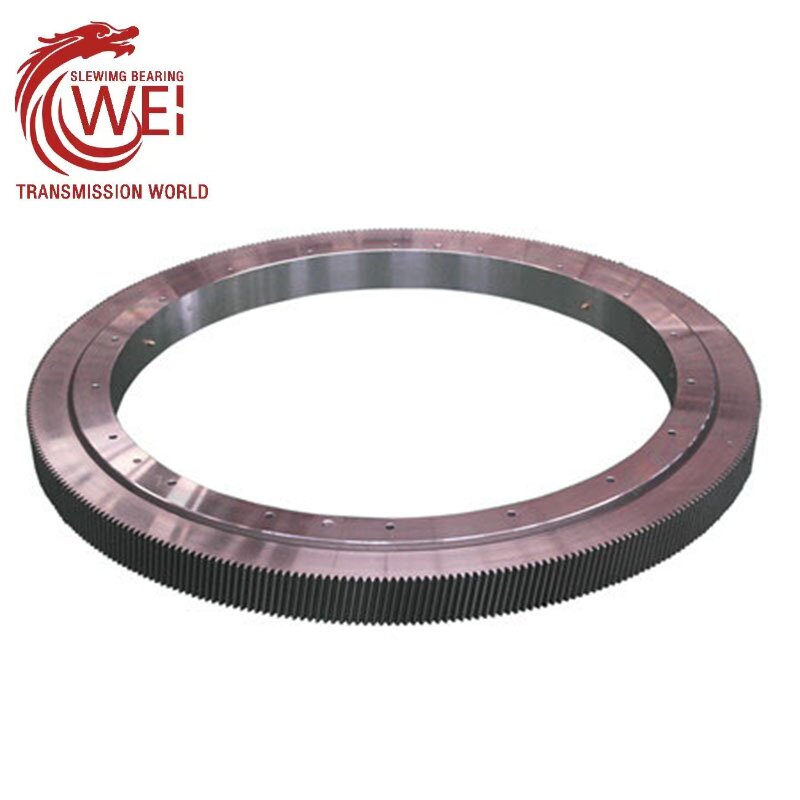

| Feature: | eight point contact double row ball | Gear Options: | Internal Gear | |

| Material: | 50Mn/42CrMo/Customized | Seals Type: | Nitrile Rubber or as requirement | |

| MOQ | 1 set | CERTIFICATE: | ISO9001:2008/SGS | |

| Bore Diameter | 758 mm | Outside Diameter | 1042mm | |

| Operating tempereature: | -30°C +70°C | Hardness: | 55-62HRC | |

| Product Name: | Double row ball with Internal Gear Slewing Bearing | Service: | OEM Service.Design Service | |

| Net Weight : | 250kgs | Rolling element: | steel ball & Spacer | |

| Warranty Period | 1 year | Testing | In house or third party | |

| MOQ | 1 SET | Size | Standard OR Customized | |

| Height | 124 mm | H.S. Code | 848210900 | |

| Packaging Details | 1.Filling with rust-proof oil 2.packing with protective layers 3.Fixed in the plywood 4.Packaging terms:Plywood case/ Pallet/Steel frame | Product Type: | tooth quenched double row ball slewing ring |

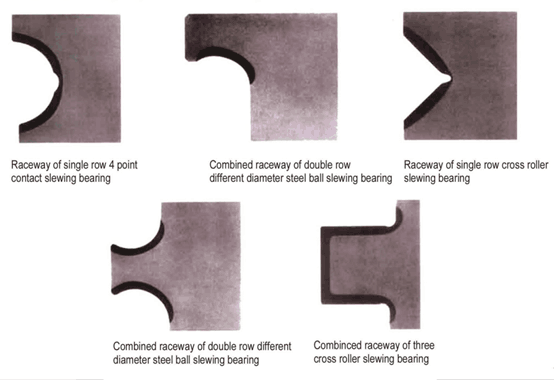

The double row ball slewing bearing has two row steel balls for structure, it has bigger load capacity comparing to single row type slewing bearing and better safety factor, and it could bear axial load, radial load and tilting moment at the same time. Double row ball slewing ring has three seat rings, the steel ball and the spacing block can be directly arranged into the upper and lower races, two rows of upper and lower steel balls with differently diameter are fitted according to the stress condition. Double row different ball slewing bearing ring’s axial and radial size are relatively large and solid in structure, so it is usually used in diameter tower cranes, truck mounted cranes etc.

| Plane deviation of mounting bracket P (mm) | ||||

|---|---|---|---|---|

| Raceway center diameter | Plane deviation of mounting bracket P (mm) | |||

| DL(mm) | single row four ball | double row ball | cross roller | |

| ~1000 | 0.15 | 0.2 | 0.1 | |

| >1000~1500 | 0.19 | 0.25 | 0.12 | |

| >1500~2000 | 0.22 | 0.3 | 0.15 | |

| >2000~2500 | 0.25 | 0.35 | 0.17 | |

| >2500~4000 | 0.3 | 0.4 | 0.2 | |

| >4000~6000 | 0.4 | 0.5 | 0.3 | |

| >6000~8000 | 0.5 | 0.6 | 0.4 | |

Compared to other rolling-element bearings, slewing bearings are thin in section and are often made in diameters of a metre or more; Slewing bearings resemble oversize aircraft control surface bearings.

Slewing bearings often use two rows of rolling elements. They often use three race elements, such as an inner ring and two outer ring “halves” that clamp together axially.

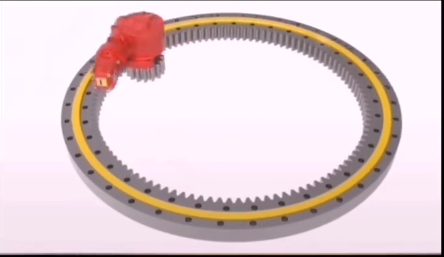

Slewing bearings are often made with gear teeth integral with the inner or outer race, used to drive the platform relative to the base.

As for other bearings that reciprocate, rather than rotating continuously, lubrication can be difficult. The oil wedge built up in a continuously rotating bearing is disrupted by the stop start motion of slewing. Instead, a hydrostatic bearing with pumped oil flow may be used.

Gear Heat Treatment

Special heat treatment design is carried out according to the different needs of specific industries for gears, mainly including induction single-tooth quenching and induction-type integral tooth quenching. Single tooth quenching is divided into tooth surface quenching and tooth surface and root quenching. After quenching, tempering treatment is carried out to make the surface hardness and the depth of the hardened layer meet the design standards. The most advantageous process is the special process of integral tooth quenching, which can improve the transmission efficiency and increase the wear resistance and impact resistance of the tooth surface, so as to meet the needs of customers.

The raceway heat treatment of the slewing bearing is realized by induction heat treatment technology. Longwei Transmission Slewing Bearing has advanced heat treatment equipment (processing equipment and testing equipment) and scientific processing technology, so that the depth and hardness of the hardened layer conform to JB /T2300-2018 slewing bearing standard.

Technical parameters required for slewing bearing selection as below:

1).Slewing bearing load (Includes axial load, radial load and tilting moment)

2). Percentage of each load and its occupation time

3). Speed or number of revolutions of the slewing bearing under each load

4).Circumferential force acting on the gear

5).Dimensions of the slewing bearing

6). Other operating conditions

The material, compressive property, abrasive resistance and hardness of balls will affect the load condition and service life of slewing bearing. Longwei slewing bearing Co., Ltd purchase balls from suppliers with high quality, and we will conduct test for the compressive property, abrasive resistance and hardness to eurens the quality of balls will meet the requirement.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.