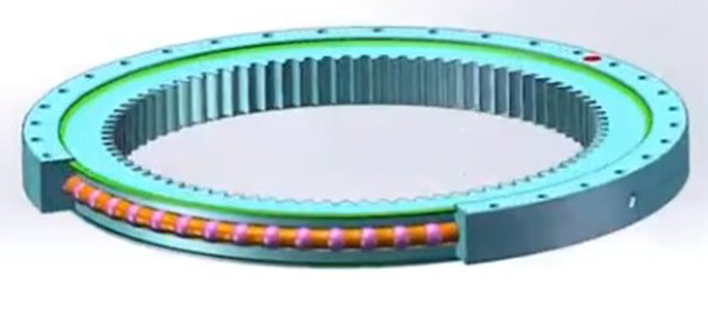

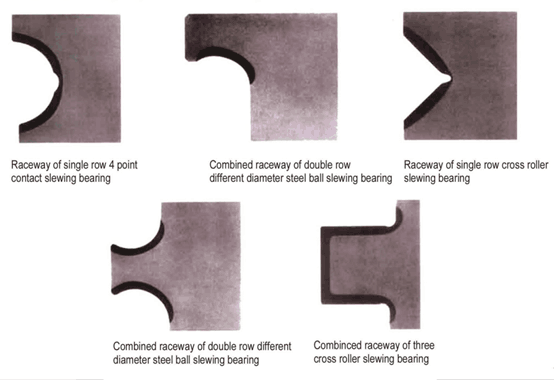

Single-row four point contact ball type slewing bearing is composed of two socket sleeves and is compact in structure and light in weight .Due to its steel balls contact with circular rollingtrack on four points,it can bear axialforce ,radial force and overturning moment at the same time

Note:

- n1 is No. of lube holes, the user can specify the lube hole position.

- n-φ can be changed to threading holes, hole diameter M, thread depth 2M.

- There are standard products in the catalog, and the inner and outer diameters are random tolerances. If there is a locating requirement for slewing bearing, please indicate the site and tolerance.

- It is standard type of our products, if you need more please contact with engineer.

| Plane deviation of mounting bracket P (mm) | ||||

|---|---|---|---|---|

| Raceway center diameter | Plane deviation of mounting bracket P (mm) | |||

| DL(mm) | single row four ball | double row ball | cross roller | |

| ~1000 | 0.15 | 0.2 | 0.1 | |

| >1000~1500 | 0.19 | 0.25 | 0.12 | |

| >1500~2000 | 0.22 | 0.3 | 0.15 | |

| >2000~2500 | 0.25 | 0.35 | 0.17 | |

| >2500~4000 | 0.3 | 0.4 | 0.2 | |

| >4000~6000 | 0.4 | 0.5 | 0.3 | |

| >6000~8000 | 0.5 | 0.6 | 0.4 | |

Gear Heat Treatment

Special heat treatment design is carried out according to the different needs of specific industries for gears, mainly including induction single-tooth quenching and induction-type integral tooth quenching. Single tooth quenching is divided into tooth surface quenching and tooth surface and root quenching. After quenching, tempering treatment is carried out to make the surface hardness and the depth of the hardened layer meet the design standards. The most advantageous process is the special process of integral tooth quenching, which can improve the transmission efficiency and increase the wear resistance and impact resistance of the tooth surface, so as to meet the needs of customers.

The raceway heat treatment of the slewing bearing is realized by induction heat treatment technology. Longwei transmission Slewing Bearing has advanced heat treatment equipment (processing equipment and testing equipment) and scientific processing technology, so that the depth and hardness of the hardened layer conform to JB /T2300-2018 slewing bearing standard.

About Longwei

Longwe Transmission slewing bearing team is committed to keep the spirit of continuous improvement and focus our strategy of strict quality control standards, quick response, prompt delivery and low price.We look forward to working on all of our customers’ growing demands. Our ability to optimize the bearing design for your specific needs is unparalleled and we will assist you throughout the design, manufacturing and implementation process.

Products type | 1.single – row four – point contact ball |

Special services | 1.slewing bearing design |

Business type | manufacturer,trading company |

Advantages | 1.ISO 9001:2008 certificate,12 years experience2.High qualified material,low MOQ,excellent quality,competitive prices, |

Material | 50Mn/42CrMo or as your requirements |

Package | 1.First lubricated, Second circled with plastic film,kraft paper,blue belt,then packaged inwooden case,last gathered in Wooden pallet.2 According to your requirements

|

Delivery time | 1.For general product , our delivery time need only 5 days is enough (goods in stock).2.If you have special technical requirements or need additional processing,we first rder need only 45 ys, if that is roller continuous order, our delivery time only need 35 ys.

|

Application fields | Mine machine, port hoisting machine, port oil transfer equipment onshore and offshorecrane,excavator,concrete machine,paper machine, plastic and rubber machine, weavemachine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipment.

|

We supplied high quality product & good service to every end user and valued distributors all over the world. We’ve enjoyed a very good reputation up to now.

Technical parameters required for slewing bearing selection as below:

1).Slewing bearing load (Includes axial load, radial load and tilting moment)

2). Percentage of each load and its occupation time

3). Speed or number of revolutions of the slewing bearing under each load

4).Circumferential force acting on the gear

5).Dimensions of the slewing bearing

6). Other operating conditions

The material, compressive property, abrasive resistance and hardness of balls will affect the load condition and service life of slewing bearing. Longwei slewing bearing Co., Ltd purchase balls from suppliers with high quality, and we will conduct test for the compressive property, abrasive resistance and hardness to eurens the quality of balls will meet the requirement.Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements and has acquired certificate of China Classification Society .

If you have any questions, pls do not hesitate to contact us.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.