Are you looking for high-quality industrial turntable bearing? As we all know, industrial turntable bearing are mainly used in heavy machinery and industrial fields. These turntable bearing power the seamless rotation of cranes, turbine generators, excavators and more.

This article will explain the types of industrial turntable bearing, how much they cost and how to find a slew bearing supplier near you.

What Are Industrial Turntable Bearing

Table of Contents

Industrial turntable bearings (slewing ring bearing ) are specialized components designed to facilitate the rotation and pivot of heavy machinery and equipment within various industrial applications. These bearings play a critical role in industries where precise and controlled movement is essential, such as manufacturing, construction, material handling, and logistics.

working principle

They work by reducing friction and evenly distributing loads, allowing for precise and efficient movement. These bearings play a vital role in enhancing the efficiency, safety, and reliability of industrial processes, making them indispensable components across a wide range of applications.

Features

Industrial turntable bearings are characterized by their ability to support both axial and radial loads, their large diameter, precision, low profile, and versatility. They play a vital role in applications that require controlled rotation and the distribution of heavy loads while maintaining stability and reliability.

What Are the Types of Industrial Turntable Bearings?

Industrial turntable bearings come in various types, each designed to cater to specific load capacities, operational requirements, and environmental conditions. The most common types include:

- Single Row Ball Bearings

- Double Row Ball Bearings

- Cross Roller Bearings

- Three-Row Roller Bearings

- Wire Race Bearings

- Internal Gear Bearings

- External Gear Bearings

- Non-Gear Bearings

- Thin Section Bearings

- Flanged Bearings

How Are Industrial Turntable Bearings Used?

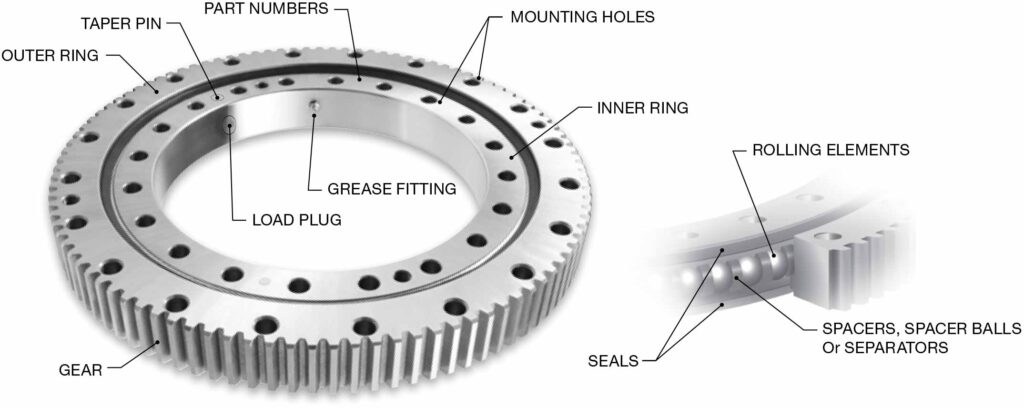

Industrial turntable bearings play a crucial role in affixing themselves firmly to a given structure. Positioned at the terminus of every shaft within machinery designed to deliver rotational movement, turntable bearings exhibit exceptional versatility by efficiently managing both thrust and radial loads. Whether facilitating clockwise rotation or ensuring a continuous, low-speed rotation, these dynamic components prove their adaptability in diverse scenarios.

These multifaceted apparatuses seamlessly integrate with an array of equipment, including cranes, grapples, forklift attachments, and various other products that necessitate the combination of rotational functionality and load-bearing capacity. Our extensive selection of bearings caters to a spectrum of applications, offering options such as flanged, rectangular, high-capacity rectangular, and rectangular cross roller varieties.

In order to align with the specific requirements of your unique applications, we present a comprehensive range of turntable bearings, each distinguished by its distinctive features and capabilities. Whether you seek a flanged configuration for enhanced stability or a rectangular cross-roller design for precision and efficiency, our offerings are meticulously crafted to meet and exceed your expectations.

Why You Need to Buy an Industrial Turntable

Turntable bearings and ball bearings, distinguished by their rugged and versatile nature, play a pivotal role in enhancing performance across a diverse spectrum of applications. The inherent advantages they bring to your operations are manifold and encompass:

Usability: The design intricacies of turntable bearings and ball bearings are manifested in the presence of strategically positioned holes within both the inner and outer rings. This thoughtful engineering facilitates effortless mounting, thereby contributing to enhanced usability.

Performance: Renowned for their robustness and versatility, turntable bearings and ball bearings stand as exemplars of strength in a compact form. Notably, they possess the remarkable ability to occupy minimal space, making them particularly advantageous in situations where spatial conservation is imperative.

Capacity: The intrinsic design and structure of turntable bearings and ball bearings are meticulously crafted to optimize load-bearing capacity. This results in bearings that excel in handling extreme moment loads, showcasing a superior capacity that is essential for applications demanding the resilience to withstand and manage substantial forces.

What Materials Can Be Used for Industrial Slew Bearings?

Industrial turntable bearings are crafted from a variety of materials, each chosen to meet specific application demands, including load capacity, corrosion resistance, and durability. The most common materials utilized for industrial turntable bearings include:

Carbon Steel: Carbon steel bearings are widely used due to their excellent strength and durability. They are suitable for applications with moderate loads and provide cost-effective solutions.

Stainless Steel: Stainless steel bearings are corrosion-resistant, making them ideal for applications where exposure to moisture, chemicals, or harsh environments is a concern. They are commonly used in food processing, medical equipment, and marine applications.

Chrome Steel: Chrome steel bearings offer a balance between strength and corrosion resistance. They are used in applications requiring moderate to heavy loads and moderate corrosion resistance.

Alloy Steel: Alloy steel bearings are engineered for high-strength applications, especially in heavy machinery and construction equipment. They exhibit enhanced hardness and wear resistance, ensuring longevity in demanding environments.

What Are the Main Applications of Industrial Turntable Bearing?

Industrial turntable bearings are versatile components that play a pivotal role in a wide range of applications, enabling controlled rotation and efficient load-bearing. Their main applications include:

Cranes and Construction Equipment: Turntable bearings support the pivotal movement of cranes, excavators, and construction machinery, allowing for precise positioning and the handling of heavy loads.

Wind Turbines: In wind energy generation, industrial turntable bearings help orient and support the massive rotor blades, ensuring optimal wind capture.

Conveyor Systems: These bearings enable smooth rotation in conveyor systems, facilitating the movement of materials in manufacturing and logistics.

Material Handling Equipment: Turntable bearings are vital in the machinery used for loading and unloading cargo in warehouses, distribution centers, and shipping ports.

Automated Manufacturing: In robotic arms and automated machinery, turntable bearings contribute to precision and controlled movement in various manufacturing processes.

Packaging Machinery: These bearings are employed in packaging machinery to facilitate the smooth and precise rotation of equipment for filling, sealing, and labeling.

Agricultural Machinery: In farm equipment like combine harvesters and sprayers, turntable bearings enable smooth rotation and support the machinery’s functions.

How to Choose Industrial Slew Bearings?

Selecting the right industrial turntable bearings is crucial to ensure the efficiency and longevity of machinery and equipment. To make an informed choice, consider the following factors:

- Load Capacity: Determine the maximum axial and radial loads the bearing will need to support. Select bearings with load ratings that comfortably exceed these requirements to prevent premature wear and failure.

- Size and Diameter: Choose a bearing with an appropriate diameter to fit the available space in your application. Consider both the inner and outer diameters, as well as the overall size, to ensure a proper fit.

- Rotation Speed: Take into account the required rotation speed of the bearing. Bearings are often rated for specific speeds, so choose one that matches your application’s rotational requirements.

- Environmental Conditions: Consider the operating environment, including factors like temperature, moisture, and exposure to contaminants. Opt for bearings made from materials that can withstand these conditions, such as stainless steel for corrosion resistance.

- Precision and Accuracy: Evaluate the level of precision required for your application. If precise positioning is critical, choose bearings with high precision ratings, such as cross roller or angular contact bearings.

- Load Distribution: For applications with varying loads and shock loads, select bearings that can efficiently distribute loads to prevent overloading and uneven wear.

- Mounting and Installation: Ensure that the bearing is compatible with the mounting and installation methods in your application. Check for flanges, mounting holes, and any special requirements.

How Much Does It Cost to Buy Industrial Slew Bearings?

The cost of industrial turntable bearings can vary widely depending on several factors. These factors include the type of bearing, size, load capacity, precision, material, and supplier. Generally, you can expect the following price ranges for industrial turntable bearings:

List of Top Industrial Slewing Bearing Manufacturers

SKF Group:

SKF is a globally renowned manufacturer of various bearing solutions, including slewing bearings. They offer a wide range of slewing ring bearings for industrial and heavy equipment applications. SKF is known for its high-quality, precision-engineered bearings and has a strong presence in the global market.

Rollix:

Rollix is a French company specializing in the design and manufacturing of slewing ring bearings. They are recognized for their precision and reliability, particularly in industries like wind energy, construction, and robotics. Rollix offers custom solutions and a variety of standard slewing ring designs.

ThyssenKrupp Rothe Erde:

ThyssenKrupp Rothe Erde, part of the ThyssenKrupp Group, is a well-established manufacturer of slewing bearings. They provide a broad range of slewing ring products designed for applications in fields such as renewable energy, mining, and construction. ThyssenKrupp Rothe Erde is known for its engineering expertise and high-quality products.

Conclusion

We hope this article has given you a more basic understanding of what an industrial slewing bearing is, why it is vital in the industry, and what are the main applications of industrial slewing bearings.

As a leading manufacturer and supplier of industrial slewing bearings, we can provide you with everything you need to know about slewing bearings. If you need to purchase professional slewing bearings, we can also provide you with related products. We look forward to hearing from you!