The world in motion – where are slewing bearings used?

Longwei slewing bearings prove themselves as important mechanical components in very diverse areas of applications. The applications and products are as varied as the slewing bearings themselves: they are individually designed and manufactured for each application. Find out which solutions are available in each industry:

Slewing ring bearings have unique load-bearing characteristics and are usually used in hoisting machinery, excavators, slewing tables, wind power generators, telescopes and tank turrets. Through the improvement of processing methods and the renewal of design concepts, slewing bearings can be applied to occasions with smaller dimensions, more complex structures and more precision.

In the machine tool industry, the slewing bearing of the standard structure adopts high-precision grades and applies preload to eliminate clearance and reduce vibration. The radial runout and diameter tolerance range of the bearing are within the controllable design range, the structure is compact, the cross-sectional size is small, and the diameter size can be as small as 50 mm, which prompts designers to reconsider the traditional bearing configuration.

Slewing bearings are used in crane bearings, crane bearings, bucket wheel bearings, marine crane bearings, shield machine bearings, ladle large bearings, and other turntable equipment bearings that are subject to radial, axial, and moment loads.

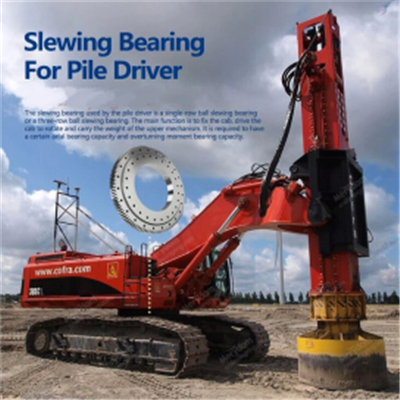

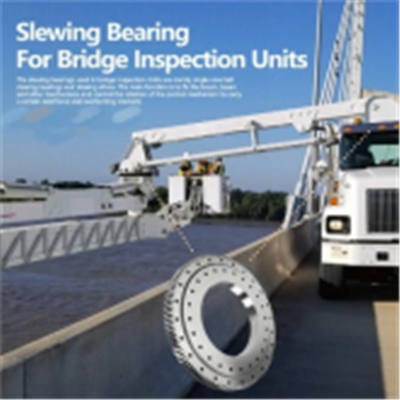

Slewing bearings are widely used. Construction machinery is the initial application field of slewing bearings and is also widely used, such as earthmoving machinery, excavators, dismantling machines, stackers and reclaimers, graders, road rollers, dynamic compaction machines, rock drilling machinery, roadheaders, etc.

A. Concrete machinery: concrete pump truck, concrete mixing and distributing boom integrated machine, belt distributing machine

B. Feeding machinery: disc feeder, sand mixer,Conveyor Type Charging Machine

C. Hoisting machinery: wheeled cranes, crawler cranes, portal cranes, tower cranes, fork cranes, cranes, gantry cranes

D. Ground treatment machinery: impact reverse circulation drilling rig, rotary drilling rig, impact rotary drilling rig, rotary drilling rig, reverse circulation rotary drilling rig, positive circulation rotary drilling rig, long spiral engineering drilling rig, diving engineering drilling rig, static pressure pile machine, pile driver

E. Engineering ships and port equipment: dredgers, sand dredgers, ship loaders, ship unloaders

F. Special vehicles: bridge inspection vehicles, fire trucks, Clean Skyscraper Windows Machine, flat beam transport vehicles, aerial work vehicles, self-propelled aerial work platforms

Add: Yicheng Village Committee Yicheng Village Committee Industrial Park,New District Street ,Xuzhou High -Tech Zone , Xuzhou,jiangsu Province ,China

sales@islewingbearing.com

Tel:+86-516-85558998

Fax:+86-516-85819994

In order to save you a lot of time and effort, the LONGWEI team created the 3D model as well as the drawings of the slewing bearings and manufacturing parts that we provided. All you need to do is put the slewing ring into your design and it will work normally. If you cannot find the right part online, we will customize slewing bearings to your exact specifications.