As a long-term practitioner in the slewing bearing market, we are committed to innovation and personalization. As part of this, we develop solutions for the most diverse applications, all of which have something in common: they go beyond ordinary.

As a market leader in slewing bearings, we lead the trend – providing a comprehensive product portfolio for various industries.

With over 20 years of experience, we can specifically meet the different requirements of various industries. We work with customers to develop suitable personalized bearing solutions.

Identify which solutions exist in each industry:

We are involved in the following industries-

Building & infrastructure,Mechanical & plant engineering,Renewable energy,Oil & gas,Precision applications,Transport & conveying engineering

Industry solutions suitable for your application

Is your industry or application not represented? Please feel free to contact us. We will find a suitable solution together.

Construction and infrastructure

Our cities are growing rapidly. Forecasts estimate that in the next 30 years, so within one generation alone, a further three billion people worldwide will move to metropolitan regions. This presents massive challenges, not only for transport and traffic, but, above all, for the infrastructure and construction of buildings.

Here at Longwei transmission , we are actively participating in shaping the cities of tomorrow with our innovative products: whether this is through passenger transport or the implementation of construction projects.

Excavators are put to use wherever the movement of earth is required: This begins with gardening and landscaping, where so-called mini or midi-excavators are used, and extends to street and house construction with medium-sized excavators, culminating in opencast and large-scale mining, where large excavators and mining excavators provide reliable support.

LONGWEI plays a crucial role in ensuring that this machinery is able to perform its hard work on construction sites every day. And it does this all around the world. Designed in close collaboration with the manufacturer, our slewing bearings constitute a key component of the respective excavator models.

A . Small Excavator :

The use of so-called small or mini excavators is becoming increasingly popular for gardening, landscaping, house renovations, and for road reconstruction. The operating weight of these types of excavators is around one to six tons for mini excavators and around seven to ten tons for midi excavators. These excavators mainly move on rubber tracks. The demands on the slewing ring between the chassis and body are particularly high here.

Medium-sized excavators

Medium-sized excavators have an operating weight ranging between 10 and 60 tons, and can have both a wheeled or a tracked chassis. The fields of application for this type of excavator are very diverse. They range from house and street construction to loading and unloading activities. This places particularly high demands on the slewing ring between the chassis and body. Since the slots at the construction site tend to be very tight, downtime must be avoided. Irrespective of whether you have interior of exterior gearing, the slewing ring must be easy to service, durable and robust.

Large excavators and mining excavators

The term mining excavator refers to the group of largest excavators with a bucket capacity of over 50 tons of material weight. These machines are mainly used in mines for the extraction of coal, ores, and other raw materials. Their higher levels of mobility constitute an advantage over bucket excavators. This is achieved by means of the bearing, which ensures a connection between the upper structure and chassis of the excavator, enabling you to swivel around the whole work area.

Large excavators and mining excavators have an operating weight of around 50 to 200 tons. They are used in quarries and other, similar spoil pile areas. These excavators’ chassis generally have a chain drive. Harsh operating conditions and high levels of dust and dirt accumulation are also particularly challenging for the slewing rings between the chassis and body. Thanks to its many years of experience, LONGWEI is always able find a suitable solution for the manufacturer, ensuring that unnecessary operational downtime is avoided.

Crawler cranes

Crawler cranes are used if the field of application is not accessible for a hydraulic excavator, for example, if a large height difference must be overcome but there is not enough space. They can extract from water and also be used in sand and gravel pits. Not even trenches for diaphragm walls are a problem for crawler cranes.

Bucket excavators

Bucket excavators are amongst the largest excavators in the world. They are mainly used to extract raw materials in large-scale and opencast mining. Bucket excavators are particularly well suited to lignite mining, given their considerable output levels of up to 240,000 tons per day.

LONGWEI bearings are used in several parts of these types of excavators to ensure that the several hundred metres high and several thousand tons of heavy machinery can be used effectively. This begins with the paddle wheel bearings, which must be especially protected against dirt, and extends to the portal bearing, which makes the swivelling of the upper structure on the chassis possible. Pivot bearings are used on the conveyor belts and spreaders, which are necessary for the handling of the spoil piles. Other applications include for bridge bucket wheel machines and drumming machines, which are used for the handling and mixing of bulk materials, and for the often 100-metre-long cantilever to which the bucket wheel is attached. Several slewing rings with various rotation axes are also used in a bucket excavator.

The accumulation of dust and dirt during extraction work is a big challenge for the technology. In order to prevent downtime due to defects, we bring our experience into collaborating with manufacturers.

Drilling Equipment

Three row ball slewing bearing for CANYON EQUIPMENT MR-A500 Excavator Drill

If pits are required without pit inclinations, as is the case for fence posts, fountains or heat pumps, drilling equipment can be used. For this, great depths must be conquered, which will result in high speeds and long intervals of operation on the slewing ring.

Their malfunctioning would delay the work, and perhaps even lead to the tool being damaged. LONGWEI can draw on its experience from various different areas of application here and develop robust and long-lasting solutions.

As flexible modes of freight transport, lorries are at the centre of global logistics. The increasing demand for transport capacity is met by ever larger modes of transport. This introduces a unique set of challenges for manufacturers of semi-trailers and trailers since these transportation vehicles must be particularly agile on the narrow streets of our cities.

Slewing bearings by LONGWEI are a key component for controllable axes. They also come in a turntable edition to be used with trailers. Drawing on their many years of experience, our engineers develop economical solutions to ensure freight transport remains safe and efficient.

The reliability, durability and ease of use of the slewing bearings made by LONGWEI not only benefits the transporting of loads, but also of people. They can be found as reliable central swivel joint bearings and motor bogie bearings in many trams and articulated buses.

Our solutions in the field of automotive engineering

Tam

Unbeknownst to passengers, our bearings provide their services smoothly and reliably in trams. Today’s trains are markedly larger and more comfortable than older models, yet travel along as narrow a rail network as before. This poses great challenges for engineers, especially when it comes to curves.

LONGWEI slewing rings help to solve this problem: Our bespoke central swivel bearings and motor bogies impart excellent driving features upon modern trains. Thanks to the durability and easy maintenance of our bearings, vehicles meet even the highest sa Fety demands despite long service intervals.

Typical products

flange type slewing bearing

Single row 4 point contact ball slewing bearing

Steering semi-trailers

The number of goods being transported on the roads is increasing more rapidly than the number of available transporters. In addition, the goods are becoming ever larger, longer and heavier. This means that semi-trailers must be upgraded too since to ensure efficient logistics, they must be able to move around securely in the existing transport network. The turning circle of the vehicle is the crucial factor here. In spite of large dimensions, it must be kept as small as possible.

Here too, slewing bearings made by LONGWEI rothe erde are used. Together with the manufacturer of the semi-trailer, our engineering team will develop a solution which enables large shipments to be carried out without interruptions and in an economical manner. Our bearings make it possible to precisely steer the additional axes of the semi-trailer. The result: good handling, even in narrow spaces. In this way, we make an active contribution to road transport security.

Lorry Trailers

Trailers are vehicles with a loading area but without their own engine. In order to increase the loading capacity of a lorry, trailers are attached to the tractor unit. In most lorry trailers, the front axis is mounted onto a pivot plate. All loads are carried using this pivot plate when driving and braking. LONGWEI turntables, which are based on experience gained from decade of service and subjected to continuous quality controls, assume the loads and make it possible for the front axis to swivel. Should you have any questions or require any information, our engineering team is always at your disposal.

Articulated bus

volvo double articulated bus

In locations where building a network of trams is uneconomical or where this cannot logistically be carried out, articulated buses represent an alternative. Nonetheless, growing cities, narrower roads, badly parked vehicles, and a growing number of passengers present a new set of issues for bus manufacturers. To enable the vehicles to smoothly manoeuvre through the city’s traffic, high-quality joint slewing rings are needed.

Our engineers can draw on their experience in the field of slewing bearings when developing the articulated buses of tomorrow. With the highest quality and reliability standards, we provide manufacturers with the optimal conditions: Buses with joint slewing rings made by LONGWEI rothe erde remain a safe mode of transport, even under the strain of an emergency brake.

Skips also called dumpers, are used on construction sites for the removal of excavation and construction materials. Everyday, hundreds of skips are used in large mining excavation fields. One single vehicle can transport a load of up to 400 tons. The skips bring valuable raw materials and excavation materials to the unloading sites, which are often far away, and where the material is either crushed or stored. A tiltable pit combined with a built-in slewing ring allows for precise unloading. Here too, solutions by Longwei offer the optimal conditions for durable and smooth operation.

Fire brigade Turntable ladders

Turntable ladders are the vehicles most commonly used by the fire brigade. With these, people can be rescued from burning buildings and from great heights. For fire-fighting operations from above and at night, fire brigade turntables can also be used as mobile lighting masts. In order to be able to safely erect and turn the ladder, the precise, horizontal alignment of the vehicle is necessary. Uneven surfaces beneath can be manually evened out using extendible supports. Depending on the terrain, however, this procedure can be time-consuming and delay life-saving operations.

For this purpose, level-evening slewing rings made by LONGWEI are the optimal solution: Special slewing rings even out the placement of the vehicle without losing any time and, thus, make safe work on the extended ladder possible.

Heavy-duty transport vechicles

Shipments of goods which exceed a given dimension or weight are classified as special shipments. For these, special vehicles are required, which allow for heavy loads and excessively long goods to be safely transported along narrow and bendy roads. Controllable wheel axes are needed for this.

LONGWEI manufactures slewing rings with which vehicle manufacturers can separately control individual axes or take forced control of the axes.

Forklifts slewing attachment

40 tons Forklifts

Forklifts are becoming increasingly important in internal logistics: The loading and unloading of lorries, internal transport and the assembling of high-bay warehouses can all be rapidly carried out by these vehicles. Moving around the smallest of spaces and swivelling the lifted load are the most significant challenges to be solved by forklift manufacturers. A forklift swivel attachment, strengthened with durable slewing rings made by LONGWEI offers manufacturers an economical and technically-sophisticated solution.

communal utility vehicles

sweep machine

Slewing rings made by LONGWEI are used in the field of communal utility vehicles, especially in the construction of refuse collection vehicles. In urban spaces, they are predominantly used for emptying comparatively small bins. In order to make the best use of the vehicles, the waste must be permanently compressed. For this reason, rear loaders with a main shaft bearing press system are popular: The waste is emptied into rotating chambers, then pulled over a screw conveyor in the direction of the tailgate which continuously presses it together. This process must function smoothly and be adjusted to suit low-maintenance, long operations. LONGWEI’S engineering team accurately design the slewing rings used to match the specified loads.

LONGWEI has been supplying high-quality, robust and reliable bearing solutions for the tunneling industry for over 10 years. Since then, over 20 bearings have been manufactured for use in tunnel boring machines.

The leading equipment manufacturers in the field of tunneling technology rely on the expertise of LONGWEI in a variety of bearing applications. Longwei is the perfect partner for these critical applications. In addition to the know-how, customers appreciate the all-round package of reliable bearing solutions that we provide, which include: engineering, production and after-sales service.

The requirements for the components of a tunnel boring machine (TBM for short) are immense, as a failure during the construction of the tunnel can not only result in unimaginably high costs and delays resulting in missed deadlines, but in the worst case also result in damage to the image and loss of reputation of the TBM manufacturer. In cases where the a bearing needs to be removed from the machine during operation, this will certainly result in significant project delays.

As a leading bearing manufacturer, LONGWEI works closely with the machine designer for each individual case to develop the optimal bearing solution for the cutter head as well as for the segment erector. Our scope of supply includes bearings for:

Customers of LONGWEI particularly value the wealth of experience in design and manufacture of slewing bearings for tunneling of up to four meters and even much larger.

Our product solutions for tunnel construction

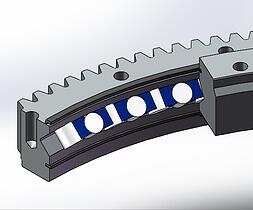

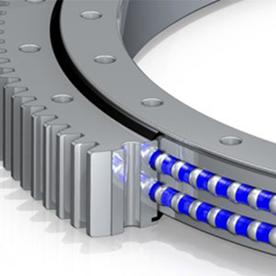

Single row Four Point Contact Ball slewing Bearing

Single Row Crossed Roller Slewing Bearing

Three Row Roller Slewing Bearing

013.50.1830 Internal Gear Single Row Ball Slewing Ring for Shield Tunneling Machine_

Cranes and lifting devices – Strong products for high loads and tilting moments

Since 2008, LONGWEI has been manufacturing and supplying rings and bearing solutions for cranes and lifting devices worldwide. Our products are the connecting element between the superstructure and substructure and thus enable the precise and safe rotation of the crane boom.

From mobile harbor cranes to shipyard cranes, offshore cranes or mobile cranes/ truck-mounted cranes – LONGWEI products are reliable components in all applications:

hoisting machinery Hydraulic crance XGC180T

Concrete mixing and distribution rod integrated machine

Our product solutions in cranes and lifting devices

multifunctional disassembly machine

Kobelco SK210D-10 multifunctional disassembly machine

Our product solutions in cranes and lifting devices

Our products are used in these cranes and lifting devices

Deck cranes

Hydraulic Telescopic Knuckle Boom Marine Ship Deck Crane

As the ship’s own loading gear, deck cranes load and unload goods from cargo ships with a very high lifting capacity. Here, robust slewing bearings are in demand. They guarantee the swivel capacity of a deck crane under adverse maritime conditions: whether at irregular intervals with heavy loads or during high periods of operation when handling lighter and mid-sized loads.

Deck cranes have replaced traditional derricks on freight ships as the on-board loading gear. Today, this term comprises all ship cranes and lever mechanisms which load or unload goods. They are an important player in fast cargo handling, especially when no cranes with sufficient lifting capacity (SWL) are available in the destination port. The lifting capacity of modern ship deck cranes lies at between 5 and 1000 tons, depending on the profile of requirements.

· Typical products: Four-point bearings, double four-point bearing, three-row cylindrical roller bearing, double-row ball bearing slewing ring

Handling cranes / shipyard cranes

In port operations, handling and shipyard cranes are an essential support in transporting products, goods, and parts. These cranes are often rail-bound and characterized by their reliable technology and high durability. Since our bearings can withstand even the highest demands and loads, they have already been used around the world for several years.

Konecranes shipyard cranes

Hose handling (HH) crane

Typical products: four-point bearing, double four-point bearing, three-row cylindrical roller bearing, double-row ball bearing slewing ring

Lifting platforms

In the crane segment, lifting platforms represent a special variant. They are primarily used to lift people to places that are difficult to access. Whether the use is intended for mobility outdoors, on roofs, over shafts or in construction sites: The security aspect plays a central role. Our components combine cost-effective designs with high precision, which are characterized by a high safety factor.

Typical products: Single row four-point bearing ball , double-row ball bearing slewing ring

Rotating crossbars / container spreaders

Container lifting spreader beam

The operation sites for crossbars are very different. These include production halls, factory premises, logistics centers and container terminals, amongst others. Resilient and powerful components are needed to transport the relevant goods. We offer specially designed slewing bearings and rings for different requirements. In addition, we also deliver reliable and cheap standard models suitable for several deployment scenarios.

Typical products: four-point bearing, double-row ball bearing slewing ring

Mobile cranes / truck-mounted cranes

Mobile cranes / truck-mounted cranes

Typical products: four-point bearings, double four-point bearings, three-row cylindrical roller bearing, profile bearings, blanks, and machined rings

Forest crane

Forest cranes are used in all fields of forestry, whether as mobile machines in the forest or as stationary units in sawmills. Working in the forest presents a special set of challenges. These include uneven ground, working on steep slopes and in the smallest of spaces. Thus, high-quality flexible units with mobile pivot arms designed for heavy loads are in demand. Our products fulfill these demands reliably and with high economic efficiency as construction and connection components.

Forestry cranes and trailers of STEPA

Machine used to load timber, mainly tree trunks, onto trailers and trucks.

Typical products: four-point bearing, double four-point bearings, three-row cylindrical roller bearings

Revolving tower cranes

A revolving tower crane can be found at almost every construction site in the world. This crane allows for the powerful vertical and horizontal movement of goods, particularly in structural engineering. Revolving tower cranes can transport loads across long distances within the radius of action. Our product portfolio offers an economically attractive range of models, extending to sophisticated special designs with high levels of resilience and durability.

Typical products: four-point bearings, double four-point bearings, three-row cylindrical roller bearing, double row- ball bearing slewing ring, profile bearing

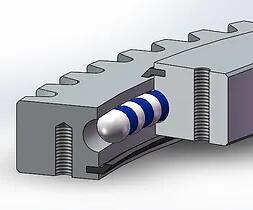

Sheaves / Pulleys

Sheaves and pulleys are used in almost every field of industry and are standard equipment in many types of cranes. Pulleys serve as suspension rope guides in the hook blocks. This requires special sheave bearings that are able to withstand the effects of sudden loads and multiple changes in direction of rotation. They are designed to be very rigid fixed bearings which not only absorb high, radial forces but also axial forces in both directions and are ideally suited for complex load distribution requirements.

Typical products: two-row cylindrical roller bearing, four-point bearing

Mobile harbor cranes

Railway cranes

Rail Cranes Lifting Capacity 15 Tons to 250 Railroad Crane COLMAR T10000FSCG

Portal crane

Heavy duty / special cranes

Offshore cranes

Liftboat Solutions for deck crane

TSC pedestal cranes

Offshore cranes are specially designed for use on the high seas and fulfill an important function in the field of oil and gas extraction, as well as in the installation and maintenance of offshore wind turbines. Our product portfolio offers a wide range of bearing designs. We will advise you comprehensively on which bearing solution ensures maximum safety for your application and represents an economically optimal design. This ensures maximum safety and an economically optimal design.

Typical products: four-point bearings, double four-point bearings, three-row cylindrical roller bearing

Truck loading cranes

If particularly bulky or heavy goods have to be loaded or unloaded onto or from trucks or other vehicles, loading cranes are needed. Irrespective of the operation site, our components fulfill the bearing requirement and load capacity for every application purpose. In doing so, we focus on solutions which remain economical for customers.

Typical products: four-point bearing, double four-point bearings, profile bearings

Construction machinery

Our solutions in the field of construction machinery

Drilling devices and attachments

Three row roller slewing bearing for CANYON EQUIPMENT MR-A500 Excavator Drill

In order to complete construction projects in as little time as possible, machines such as soil drilling devices, skips, concrete pump cantilevers, vibrating rollers, wheel bearings and pivot bearings are indispensable.

LONGWEI slewing bearings are developed to withstand hard operating conditions around the world. In close collaboration with customers, our engineers develop economic solutions, which are perfectly tailored to individual demands.

A basic device with different attachments: Here, provides the optimal solution. Our experiences gained from the field of stand-alone devices are indispensable when it comes to attachments’ application scenarios and their specific operational conditions. slewing rings are designed to dependably meet expectations in terms of ease of service, reliability and durability.

SKIPS

Skips, also called dumpers, are often used on construction sites for the removal of excavation and construction materials, since the tilting device enables fast and precise emptying. delivers bearings for the built-in slewing ring, which allow for durable and uninterrupted operation.

Concrete pump cantilevers

Three row ball slewing bearing for XCMG concrete pump truck dimensions Concrete

Concrete is the most commonly used construction material. A concrete pump is used to transport the mass of concrete quickly and efficiently to areas which are difficult to access. A pivot arm which aligns the concrete pump’s nozzle with the desired location is required for this. A slewing ring makes sure that the pivot arm can be perfectly controlled. When developing and constructing slewing rings, pays close attention to ensuring the latter’s precision and robustness meet the demands of construction sites around the world. High tilting moments when extending the concrete pump cantilever are reliably transmitted to ensure the pump operates safely.

Vibration rollers

compress soil and asphalt. A slewing ring in the break joint makes this type of roller very flexible. The front roller can be precisely controlled. This allows the vibration roller to reach the ground which needs to be compressed without the need for manoeuvring. This results in great time savings by reducing operational time at the construction site and by making the ground areas worked on more quickly accessible again. Our engineers have developed a product that withstands the hard operational conditions and strain caused by dust, dirt and heat that remains economical for roller manufacturers and guarantees reliability and ease of service for users.

Typical products

Wheel and swing loaders

Double row ball slewing bearing for KOMATSU WE1150 Wheel

loaders Light type slewing bearing for Caterpillar 988G Wheel loaders

Wheel and swing loaders are amongst the most versatile machines used for the transporting and removal of goods on a construction site. Since the attachments can be changed, there is a large range of operational areas. slewing rings in the break joint make it possible for these construction machines to move fast and flexibly around a small space. Of course, we also ensure the slewing rings are as robust and durable as possible.

Typical products

Add: Yicheng Village Committee Yicheng Village Committee Industrial Park,New District Street ,Xuzhou High -Tech Zone , Xuzhou,jiangsu Province ,China

sales@islewingbearing.com

Tel:+86-516-85558998

Fax:+86-516-85819994

In order to save you a lot of time and effort, the LONGWEI team created the 3D model as well as the drawings of the slewing bearings and manufacturing parts that we provided. All you need to do is put the slewing ring into your design and it will work normally. If you cannot find the right part online, we will customize slewing bearings to your exact specifications.