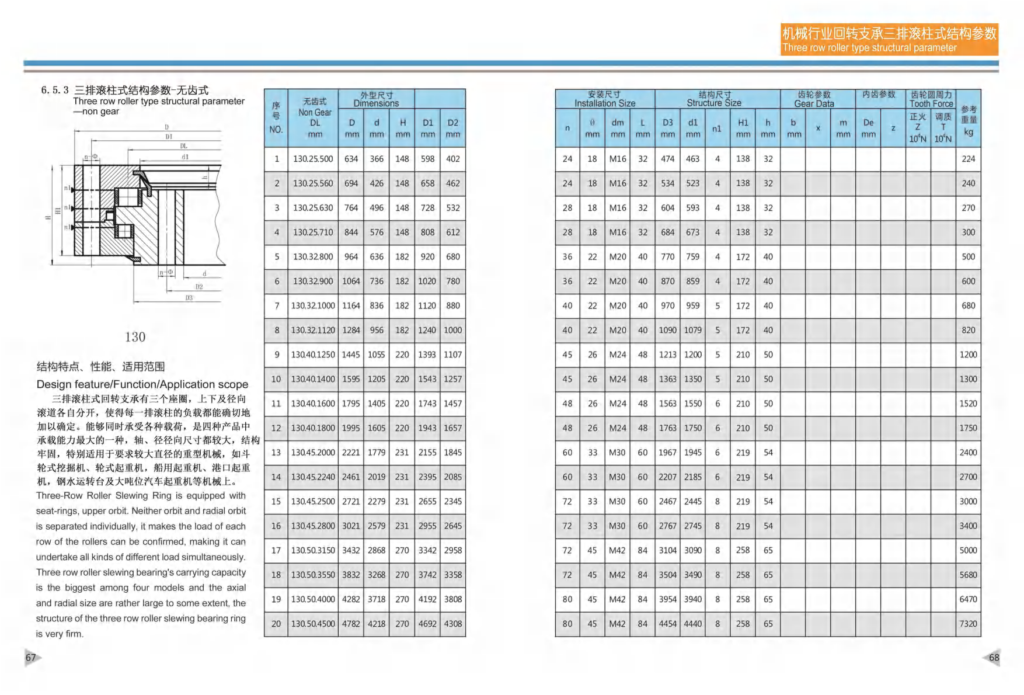

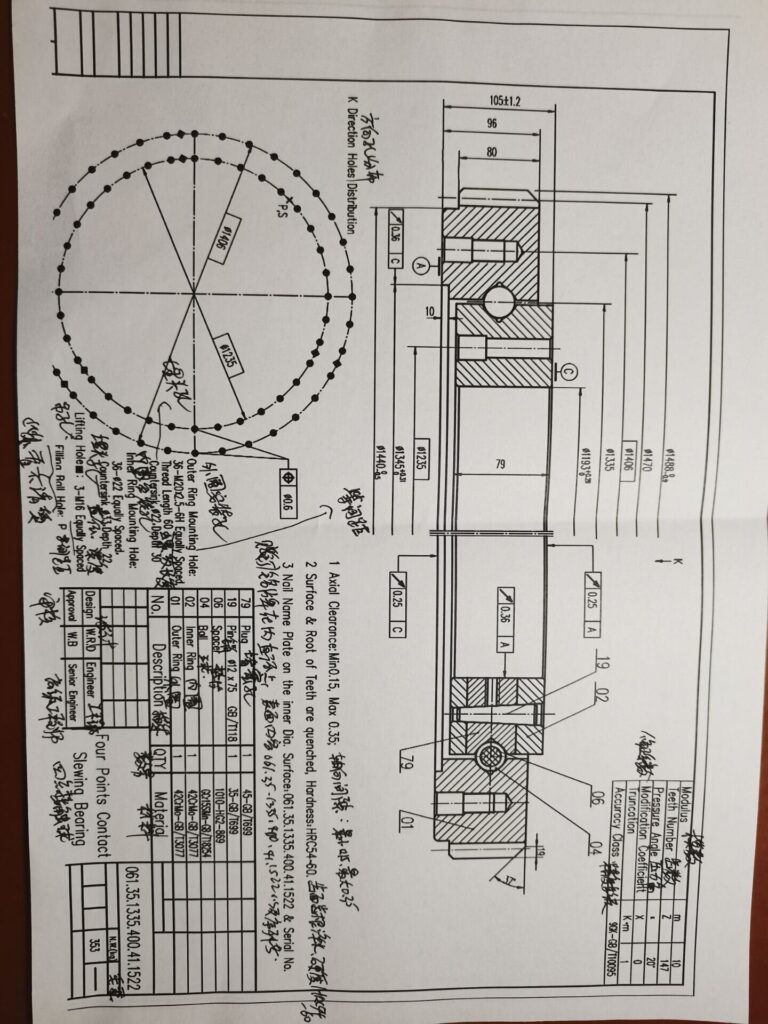

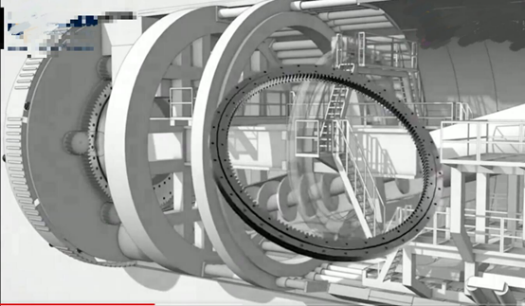

The three row roller slewing bearing is a kind of three row’s roller type pivoting support structures as claimed in claim 1 is characterized in that: the inner ring mounting hole that on inner ring, offers axial setting; On outer ring, offer the outer ring mounting hole of axial setting; Distance between the axis of the axis of inner ring mounting hole and main shaft is less than the distance between the axis of the axis of outer ring mounting hole and main shaft ; Offer a last trim ring mounting hole that cooperates with inner ring mounting hole at last trim ring, last trim ring offers trim ring mounting hole on another that cooperates with outer ring mounting hole.

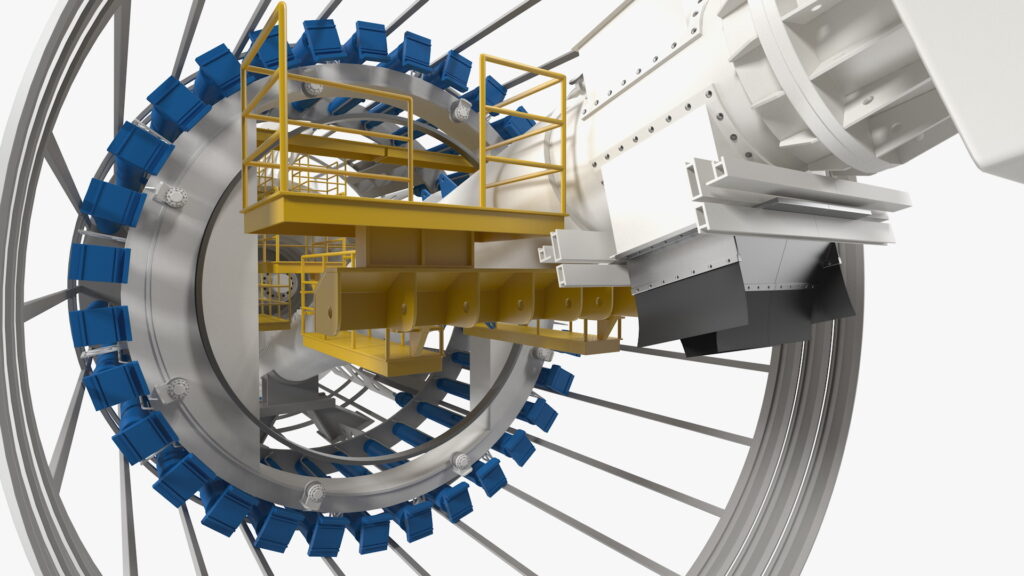

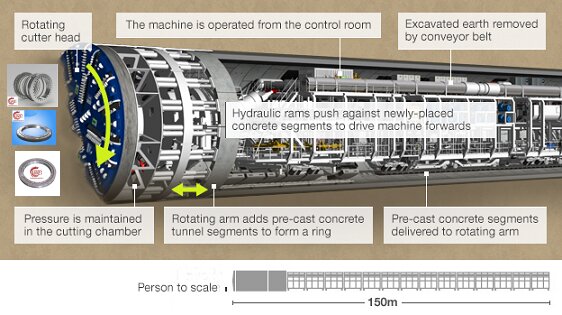

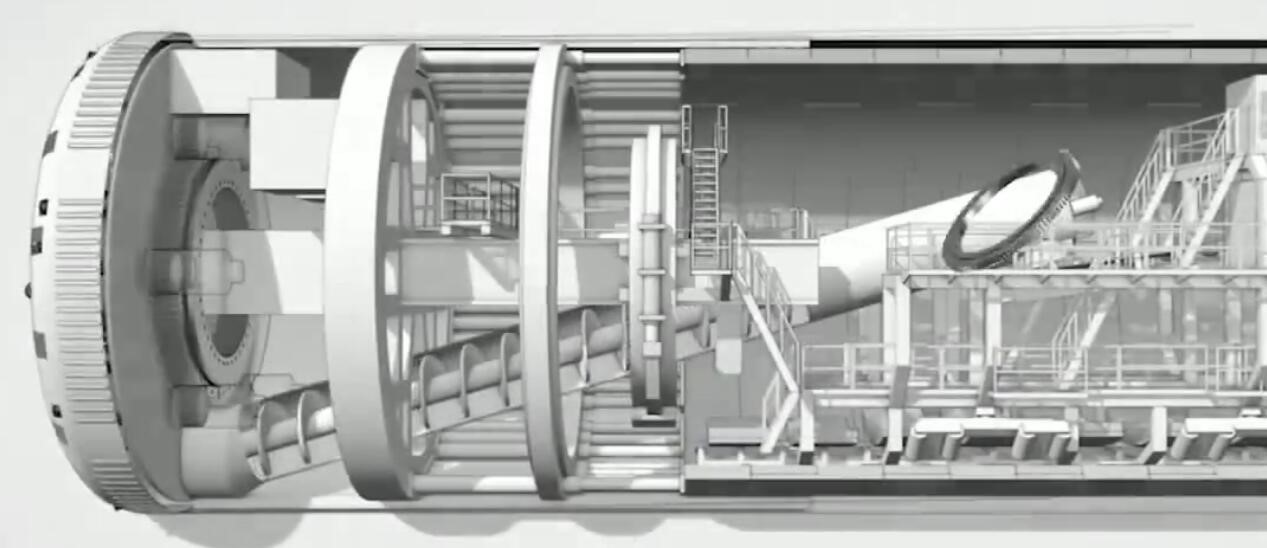

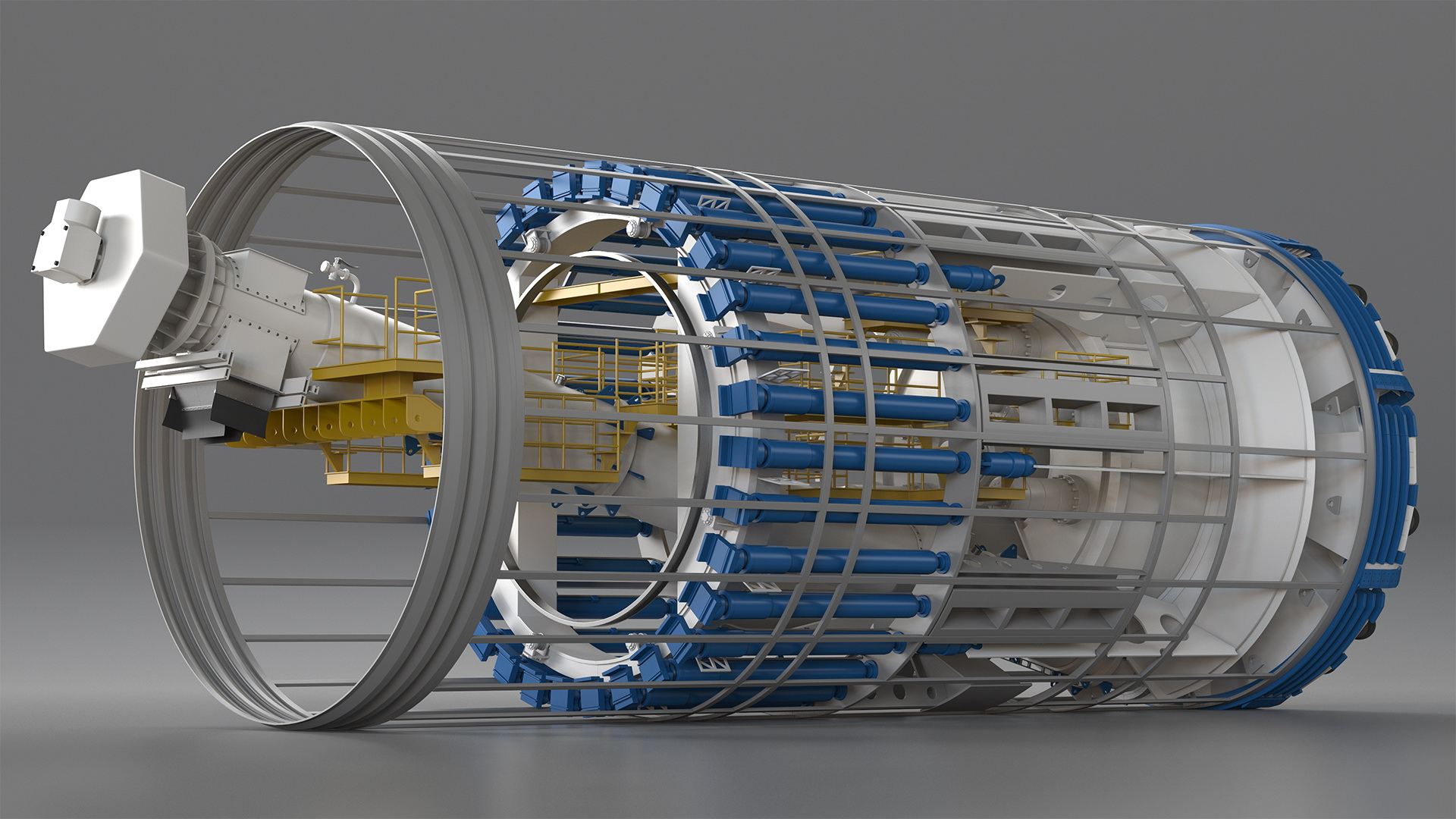

.A tunnel boring machine (TBM), also known as a “mole”, is a machine used to excavate tunnels with a circular cross section through a variety of soil and rock strata. They may also be used for microtunneling. They can be designed to bore through anything from hard rock to sand. It always use the three row roller slewing bearing.

The slewing bearing can rotate independently in three directions; the slewing bearing has simple, compact and reasonable structure; and the slewing bearing has high cost performance, is convenient to maintain, and satisfies the requirements of accuracy, bearing and multi-function of the device.

Longwe Transmission slewing bearing team is committed to keep the spirit of continuous improvement and focus our strategy of strict quality control standards, quick response, prompt delivery and low price.We look forward to working on all of our customers’ growing demands. Our ability to optimize the bearing design for your specific needs is unparalleled and we will assist you throughout the design, manufacturing and implementation process.

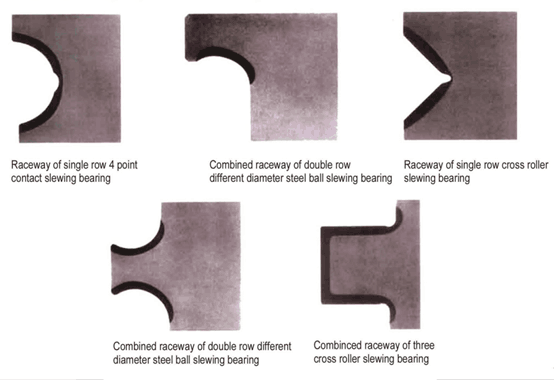

Products type | 1.single – row four – point contact ball |

Special services | 1.slewing bearing design |

Business type | manufacturer,trading company |

Advantages | 1.ISO 9001:2008 certificate,12 years experience2.High qualified material,low MOQ,excellent quality,competitive prices, |

Material | 50Mn/42CrMo or as your requirements |

Package | 1.First lubricated, Second circled with plastic film,kraft paper,blue belt,then packaged inwooden case,last gathered in Wooden pallet.2 According to your requirements

|

Delivery time | 1.For general product , our delivery time need only 5 days is enough (goods in stock).2.If you have special technical requirements or need additional processing,we first rder need only 45 ys, if that is roller continuous order, our delivery time only need 35 ys.

|

Application fields | Mine machine, port hoisting machine, port oil transfer equipment onshore and offshorecrane,excavator,concrete machine,paper machine, plastic and rubber machine, weavemachine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipment.

|

We supplied high quality product & good service to every end user and valued distributors all over the world. We’ve enjoyed a very good reputation up to now.

Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements and has acquired certificate of China Classification Society .

If you have any questions, pls do not hesitate to contact us.

Gear Heat Treatment

Special heat treatment design is carried out according to the different needs of specific industries for gears, mainly including induction single-tooth quenching and induction-type integral tooth quenching. Single tooth quenching is divided into tooth surface quenching and tooth surface and root quenching. After quenching, tempering treatment is carried out to make the surface hardness and the depth of the hardened layer meet the design standards. The most advantageous process is the special process of integral tooth quenching, which can improve the transmission efficiency and increase the wear resistance and impact resistance of the tooth surface, so as to meet the needs of customers.

The raceway heat treatment of the slewing bearing is realized by induction heat treatment technology. Longwei transmission Slewing Bearing has advanced heat treatment equipment (processing equipment and testing equipment) and scientific processing technology, so that the depth and hardness of the hardened layer conform to JB /T2300-2018 slewing bearing standard.

FAQ

1: How to order?

Please refer to the help under the single payment.

2.What are the shipping methods?

Ocean shipment to the port close to your city; Air shipment to the airport close to your company; Door to door service by international express.

3.When can I get the price?

We usually quote within 12 hours after we get your inquiry. If urgent to get the price, please call us or tell us by email , we will regard your inquiry priority.

4.You are a trader or a manufacturer?

We are an industry and trade integration business, our factory located on Xuzhou City.

5.How about the payment terms?

We usually accept T/T or L/Cat sight . other terms also could be negotiated.

6.What is your minimum order?

It depends on what you are buying. Normally, our minimum order is 1pcs.

7.What is your delivery time?

If there are any parts in stock , our delivery time is only 3-7 days. If our standard model,the delivery time is around 25 days,if non-standard model,the delivery time is 38~45 days.

Reviews

There are no reviews yet.