In addition to various construction machinery, the scope of application of slewing bearings has gradually expanded. At present, equipment platforms such as port equipment, metallurgical equipment, Artificial intelligence , Military industry, Food industry , and drilling platforms have began to use slewing bearings to replace original bearings on a large scale.

these slewing rings without preload are robust and proven under very demanding operation; they place only slight demands on the flatness and perpendicularity of the adjacent construction

– they are suitable for applications with low requirements for accuracy and rigidity of the bearing arrangement, for example in simple metalworking machines, wind power equipment and construction machinery

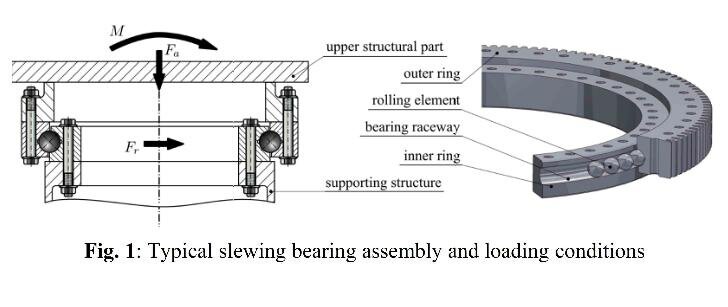

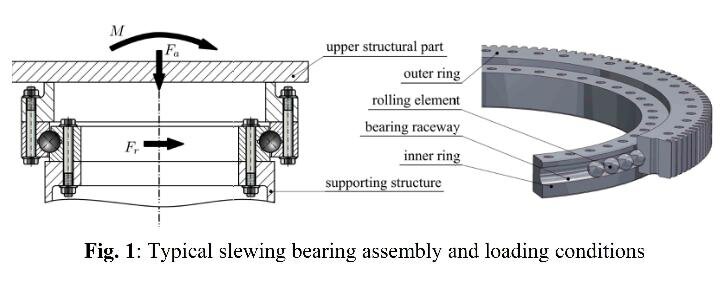

The Single Row Four Point Contact Ball Slewing Bearing is composed of 2 seat rings.It features compact in design,and light in weight.The balls contact with the circular race at four points,via which the axial force,radial force and resultant moment may be born simultaneously.

It may be used for slewing conveyer, welding arms and positioners,light,medium duty cranes,excavators and other engineering machines.

Product available including: Single and Double Row Ball, Three Row Roller, Cross Roller Sealed and Unsealed Internal Geared, External Geared and Non-Geared Clearance or Preloaded

–We respected for our quality and cost effective

–We provide custom bearing designs that meet specific customer requirements

— Timely reply.Quotes are turned around in 24 to 48 hours.

FAQ :

1 LW Slewing Bearing Heat Treatment

Heat Gear Slewing Bearings are in the majority of cases supplied with spur tooth. Stub teeth also is ok.There are two kinds of tooth hardening. They are normalizing and tempering, According to the different applications, there are two ways of quenching. They’re whole tooth quenching and single-tooth quenching. Single-tooth quenching can be divided into tooth surface & root quenching and tooth surface quenching.

2 . The Calculation of Slewing Bearing.

Static load capacity

The determined loads must be multiplied with a factor fstat allocated to the application. The product Fa’ or Mk’ must be below the static critical load curve of the selected bearing.

With regard to radial loads in load combinations

Fa = axial load

Fr = radial load

Mr = tilting moment

3 Protection Against Corrosion

We make Protection Against Corrosion on surface of bearing,and make couple of packing paper.

4.Customize.

Yes,we have professional technical terms.

5.Warranty:

General 1 year.

- Reliable reputation.

Reviews

There are no reviews yet.