About Longwei

About US : The story of Longwei began in 2004, As the main technical director and one of the production workshop directors of Xuzhou Rote Eide Slewing Ring Manufacturing Co., Ltd., Mr. Zhao chose to leave due to the expiration of his labor contract and started his entrepreneurial career.

Our factory is located in Xuzhou City, Jiangsu Province, China, which is known as the capital of construction machinery in the world.

Due to the presence of XCMG, Caterpillar, and ThyssenKrupp Xuzhou Rothe Erde slewing-bearing companies, the region has gathered a large number of the world’s most outstanding talents, funds, and technology related to construction machinery and its accessories.

For 20 years, we have been committed to the R&D, design, manufacturing, and service of various slewing bearing products, LONGWEI is a professional slewing solution supplier with slewing bearing, The company has strong technical strength, strong production capacity, and complete testing equipment, enabling us to provide 2000 sets of slewing bearing per month.

Renyu Zhao: The CEO of LONGWEI

TRANSMISSION : We help global customers and provide the best solutions when they face serious challenges

Products

Special Applications Require CustomsEd Solutions. This is why our products are depended and constructed in completion. GH Close Collaboration, We Develop Solutions Which are unrivalled in Terms of Construction, Material Quality and Performance.

Day after day, LONGWEI slewing bearings prove themselves as reliable rotational connection elements in a wide range of application areas. Worldwide, we always offer solutions that are unique in terms of design, quality, material selection and performance. The design and pro induction are exactly carried out according to the individual customer requirements.

We manufacture all main components in-house. The diversity of applications and the function of the slewing bearings is also reflected in the range of dimensions in which they are supplied:

Over the past twenty years, the guests we have served and will serve include SANY, KOMATSU, XCMG, CATERPILLAR, ZOOMLION, DOOSAN, VOLVO Construction Equipment, SUNWARD, KOBELCO, KUBOTA, HITACHI, BOBCAT, GOLDWIND, ANKE , GE Healthcare, SIEMENS Healthineers , PHILIPS Healthcare, KUKA YOUNG POTENTIAL AWARD , Seiko Epson Corporation, Yaskawa Electric Corporation, FANUC ABB, GROUP , Rolls-Royce , BAE SYSTEMS , Aenta,SANDVIK ,METSO QUTOTEC ,Epiroc ,Terex ,TetraPak ,KRONES ,KHS,SYNTEGON ,Sidel ,YOUNGSUN ,ZHONGYA ,HUALIAN & LiuGong etc.

Thanks to our extensive experience in both slewing bearing designing an production ,develops and manufactures high-quality components for customers from production develops and manufactures high-quality components for customers from diverse industries. As an experienced partner, we boast extensive know-how and expertise and optimize our components for specific applications. As a customer you benefit from customized solutions with compatible components.

President Sales & Marketing : MR.PARKER

Our slogan: Quality is gold, price is silver, delivery time is iron

Low failure rate

We have developed industry leading calculation procedures and adhere to strict quality requirements in order to provide the highest quality products.

Flexible, individual bearing design

From single piece requirements to volume production demands – customized solutions are developed for every project.

Future-oriented product portfolio

The portfolio is continuously developed and improved so that the product portfolio is always state-of-the-art.

As broad as the areas of application of slewing bearings are, their individual designs are equally diverse.

As the leading manufacturer of slewing bearings, our aim is to create solutions and manufacture products that have an above average service life, even while being subjected to harsh operating conditions.

How Does a Slewing Bearing Work

A slewing bearing, also known as a slewing ring, is a machine element that absorbs all axial and radial forces and the resulting tilting moments, in a single, self-retaining and ready-to-install bearing unit.

The goal is to quickly and easily transfer the forces acting on the slewing bearing to the adjacent structural machine elements. The overall design of the product, including the inner and outer rings, the gear cutting, rolling elements and mounting holes, enables it to transmit the applied loads and allow smooth rotation at the same time while maintaining a compact footprint. Slewing bearings enable and facilitate the rotational motion of wind turbines, excavators, cranes and tunnel boring machines, just to name a few. The slewing bearing offers many advantages compared to other solutions, including taking up significantly less space, weighing less and being more cost-effective in most cases.

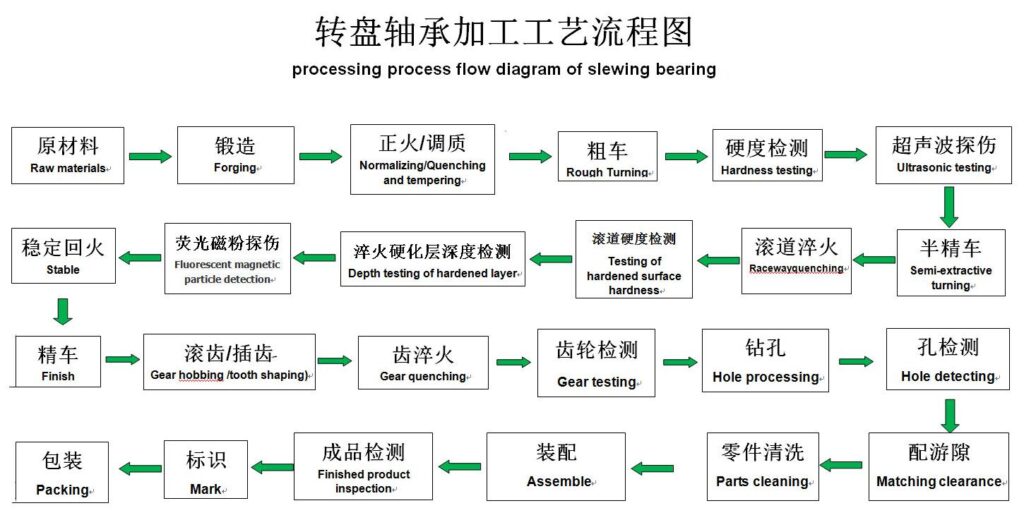

The Production Process –

How a Billet Steel is Turned into a Slewing Bearing

The challenge of the production process is to manufacture a product that can withstand the intended operating conditions over the long term. Among others, these are:

- Installation, also in extreme conditions, e.g. in offshore wind turbines.

- High axial and radial forces, e.g. in machines used in the construction industry and infrastructure development.

- Tilting moments, e.g. in large crane systems.

- Heavy loads, e.g. in transport and conveying technology.

Find out how a slewing bearing is created through processing a billet steel :

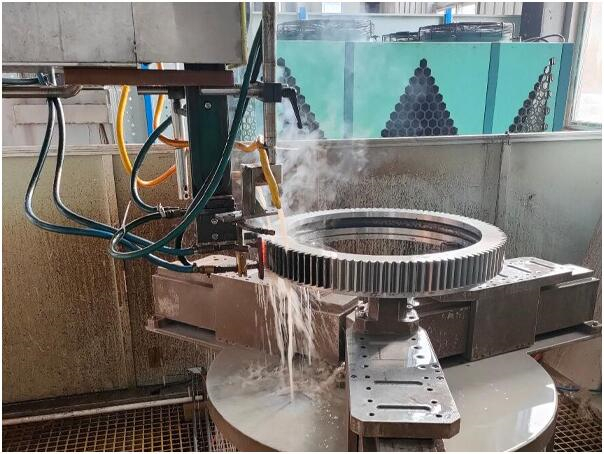

Factory Tour

Why Choose Us

Exceptional services

We provide exceptional services to all of our customers and put them at the heart of our decisions.

Fast Delivery

We have established a core project improvement team to ensure the delivery time of our customers.

Quality Assurance

Quality inspection runs through the entire project. We strictly follow the ISO 9001 quality standard.

Contact Us for the Best Quote

We help you avoid pitfalls and deliver the quality and value your slewing bearings demand, on time and on budget.