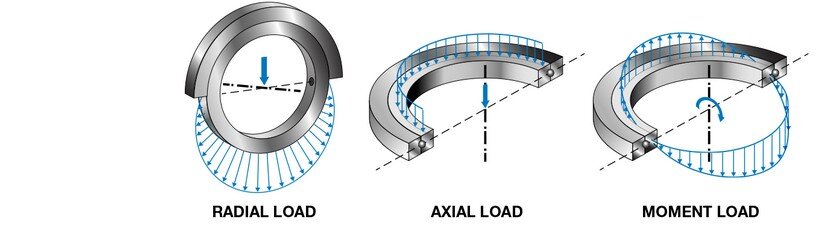

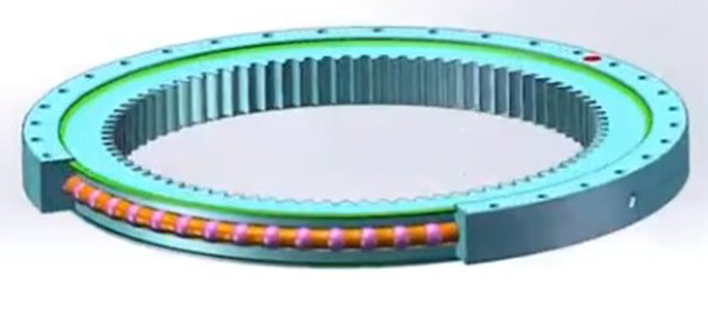

The single row four point contact ball slewing bearing is composed of two seat rings, which design in compact structure and light weight, steel ball contact with the circular raceway at four point, it can bear the axial force, radial force and the tilting moment at the same time.

It can be used for slewing conveyer,welding manipulator, light & medium duty crane, excavator, and other construction machinery.

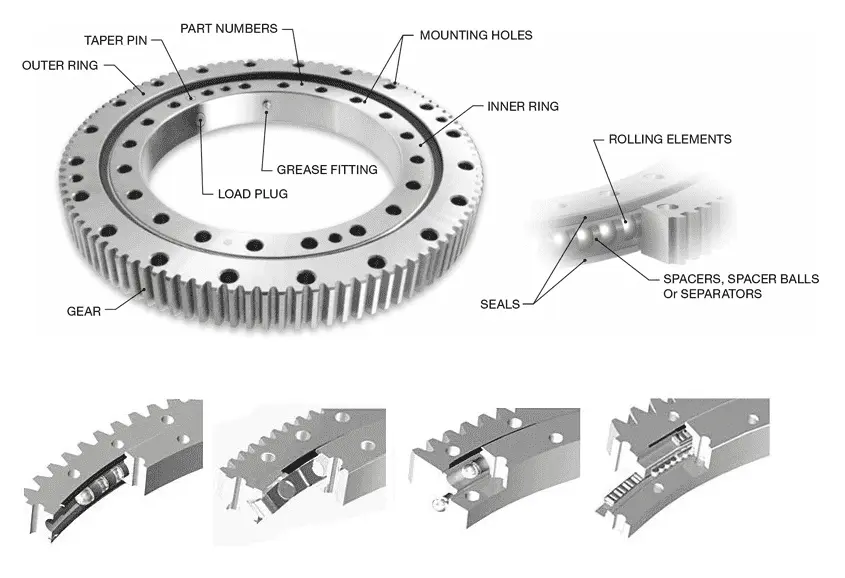

Slewing ring bearings are comprised of two rings, each of which contains a precision raceway that is induction hardened on the surface to a specified depth. Each ring is made from a medium carbon steel forging.

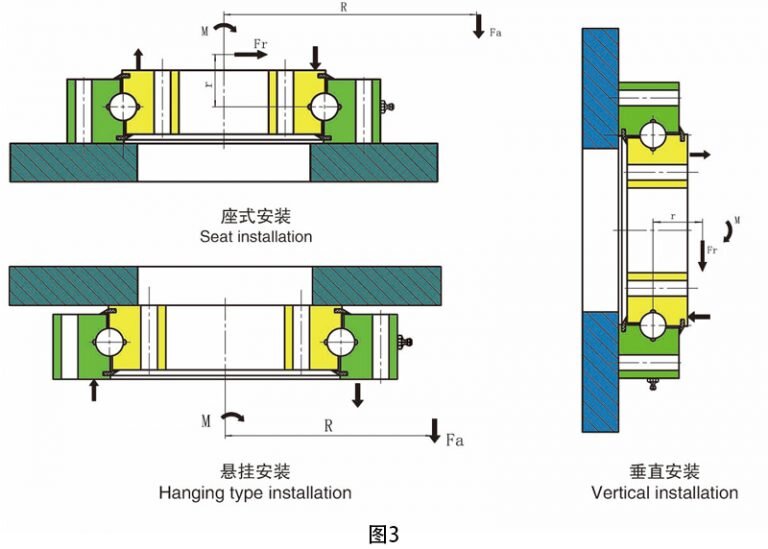

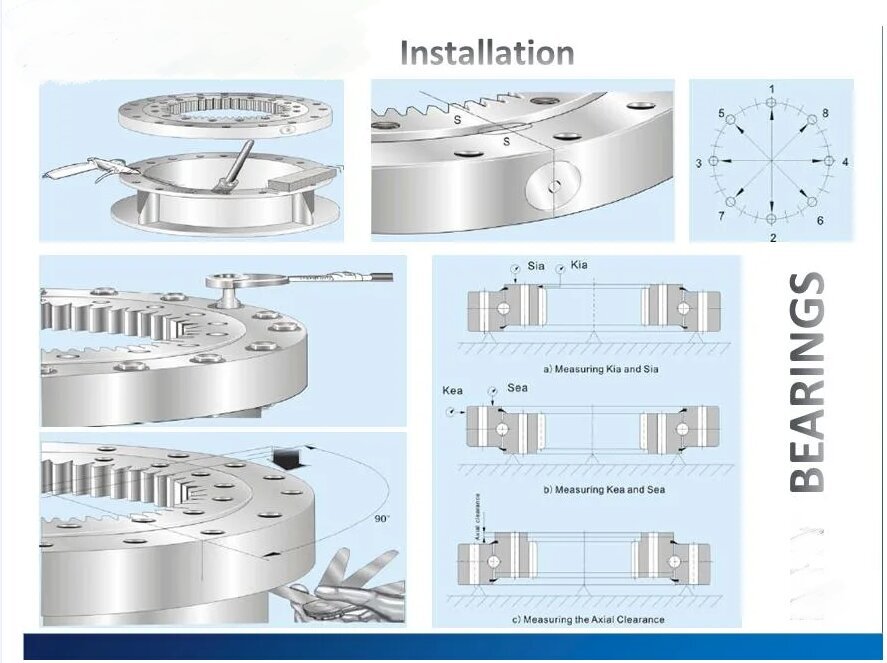

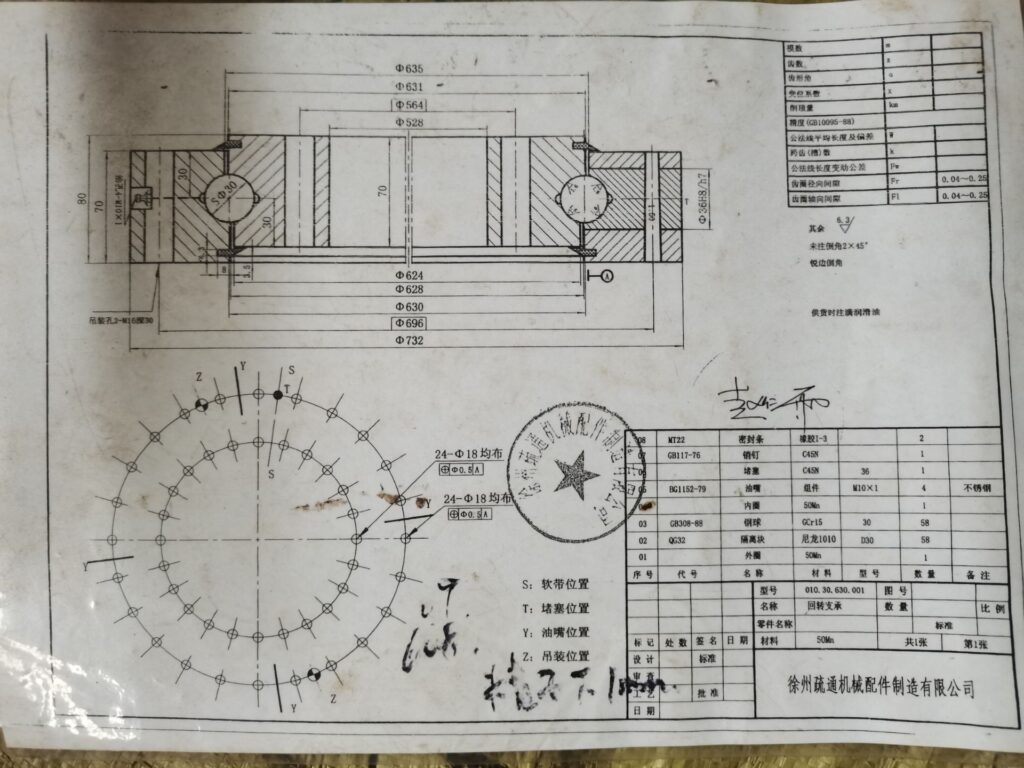

Mounting holes are generally spaced around the faces of the inner and outer ring along a uniform bolt circle and equal spacing. These holes can be thru holes, tapped holes, blind tapped holes, counter-bored holes, etc. Sometimes bolt circle or spacing requirements need to be customized to meet the demands of a specific application, in which case custom options are available. In the case of either the standard part numbers listed in this catalog, or other custom versions provided the equipment designer, manufacturer, or user is responsible to determine that the mounting design is adequate.

Slewing ring bearings can be supplied as ungeared, or with gears on either the ID of the inner ring or the OD of the outer ring. Gears are typically a standard stub involute spur gear with backlash provisions and AGMA Q8 quality minimum.

Details for each bearing can be found in the enclosed dimensional tables, and drawings are available. Custom gear configurations are also available.

At least one grease fitting is included in one of the rings. The quantity may increase with the diameter of the bearing. For bearings with gears, the grease fitting(s) are located on either the ID or OD of the ungeared ring. For ungeared bearings,come equipped to accommodate grease fittings on either the inner or outer ring. Custom quantities, locations and configurations for grease fittings are available.

- Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

- We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

- With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

- Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

- Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

FAQ :

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

5.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

Reviews

There are no reviews yet.