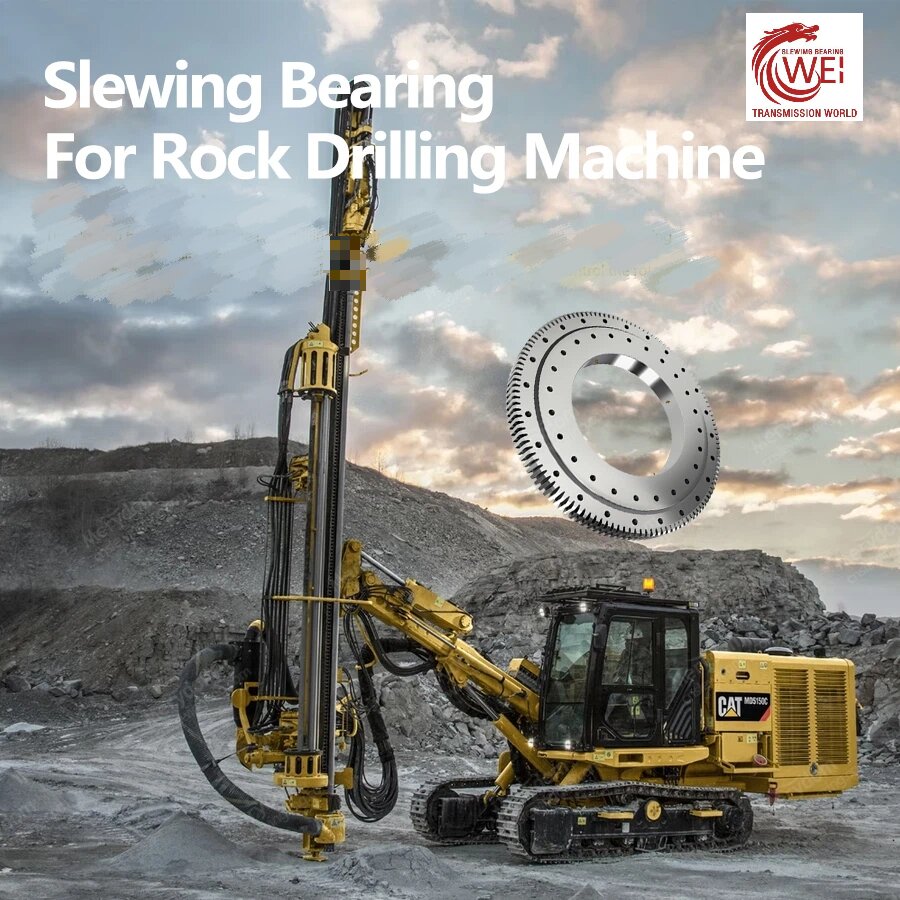

Selecting a suitable slewing bearing can effectively improve the safety and stability of the equipment, and tooth quenching can improve the wear resistance of the teeth, thereby increasing the service life of the slewing bearing.

Application principle of slewing bearing

The motor or reducer drives the pinion to rotate, and the pinion drives the slewing bearing to rotate, so that the upper mechanism connected to it rotates with it, so as to control the steering of the cab and the mechanical arm. The slewing bearing used in rock drilling machinery is required to carry large axial force, overturning moment, impact force and gear circumferential force, and has higher requirements on the clearance, installation size, gear wear resistance, heat treatment process and material of the slewing bearing.

| Plane deviation of mounting bracket P (mm) | ||||

|---|---|---|---|---|

| Raceway center diameter | Plane deviation of mounting bracket P (mm) | |||

| DL(mm) | single row four ball | double row ball | cross roller | |

| ~1000 | 0.15 | 0.2 | 0.1 | |

| >1000~1500 | 0.19 | 0.25 | 0.12 | |

| >1500~2000 | 0.22 | 0.3 | 0.15 | |

| >2000~2500 | 0.25 | 0.35 | 0.17 | |

| >2500~4000 | 0.3 | 0.4 | 0.2 | |

| >4000~6000 | 0.4 | 0.5 | 0.3 | |

| >6000~8000 | 0.5 | 0.6 | 0.4 | |

Why choose Longwei transmission slewing bearings

A pioneer in slewing bearing field, rich experience, can do design, produce, mounting guide

Small order accepted

ISO certified company

Variorum models

7*24hours hotline to help you with your cranes

Strict quality control system to ensure quality for slewing bearing

Longwei transimission Slewing Bearing Types

Longwei transmission slewing bearings can be divided into the following types as per their structures:

single row four point contact ball slewing bearing,

single row cross roller slewing bearing,

double row different ball diameter slewing bearing,

three row cylindrical roller slewing bearing and roller/ball combination slewing bearing.

And all these types of slewing bearings can be further divided into bearings without gears, bearings with external gears and bearings with internal gears.

Slewing Ring Bearings——Packaging Details:

Step 1: Covered with the anti-rust oil

Step 2: wrapped with the plastic film;

Step 3: Packed with Kraft paper and professional belts;

Step 4: Put into wooden box to avoid the rust or the moist;

Remark: Normally, plastic film+ Kraft +belt+ wooden box, but customized packing available,

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.